3D printing makes the car lighter and stronger

October 20, 2017 -The Chinese University Student’s Formula Race Car Competition has always been intense and the use of 3D printing has accelerated the designs. Farsoon has contributed to the development of these race cars for several years and in 2014 the Hunan University racing team, sponsored by Farsoon, won the championship. This annual car design and manufacturing competition is organized by college engineering students in automotive and related engineering and sciences. Now in its fifth year of collaboration, Farsoon will provide technical support for the Changsha University of Technology.

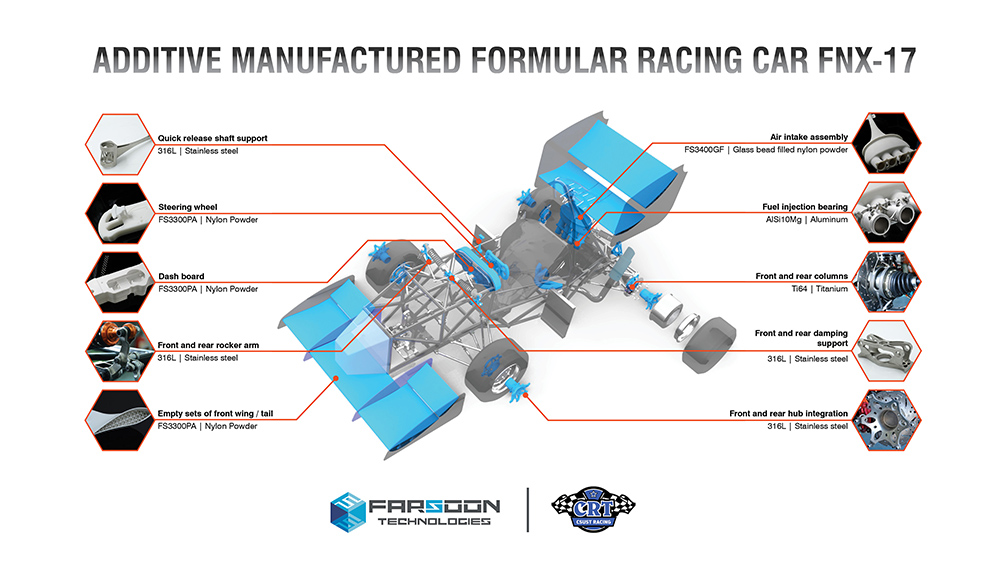

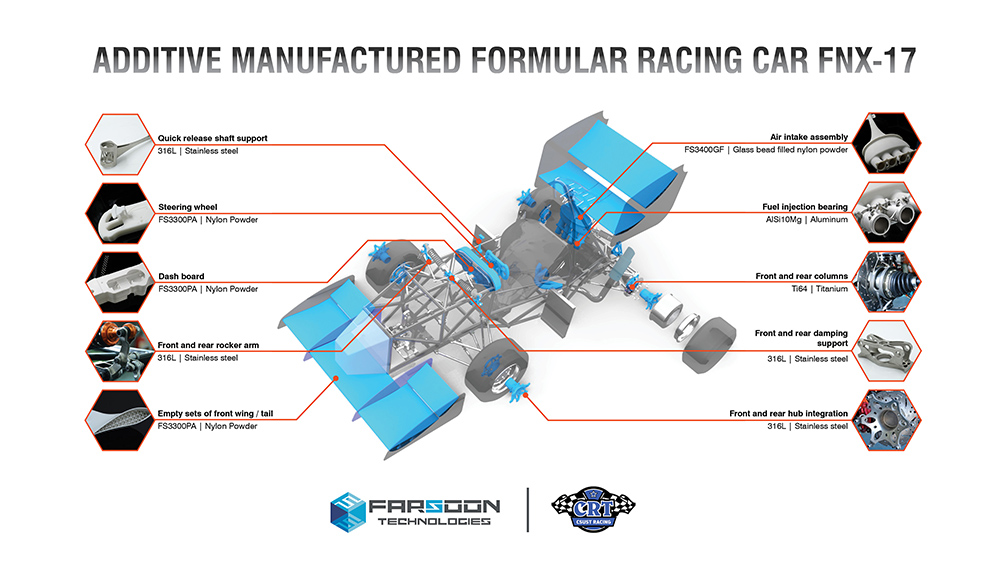

This FNX-17 car builds on years of experience and the use of 3D printing technology to achieve the required lightweight, high strength parts. The steering control, column, intake assembly, rocker and others more than 30 key components were created using Farsoon 3D printing technology. Parts for the race car were manufactured using high strength polymers and metals. In fact, 41 parts were created using metal 3D printing technology. Many of the components create a seamless body design making the structure lightweight and stiff, resulting in a design that is only 250KG with a maximum speed of 100Km / h.

Compared with the traditional forging, casting and other complex processes, 3D printing technology can reduce the production time to a fraction of the original 6–8-month production cycle time. 3D printed parts have mechanical properties that meet or exceed castings, making them a reliable alternative to other manufacturing methods.

“3D printing technology has completely changed the development process of college students’ formula racing,” said Mr. Yuan Xiang, associate professor of the formula race car racing team of Changsha University of Science and Technology, said: “3D printing racing parts can meet the needs of personalized customization, not only to ensure that parts are assembled precisely and quickly, but they can also be used to ensure the effectiveness of key functions.”

Yuan added: “The use of Farsoon 3D printing technology produced performance parts that were more stable. The use of aluminum and other materials, making the entire body lightweight, is conducive to speeding the car while withstanding the durability test. Through a series of tests and experiments, 3D printing technology is widely and maturely applied to the formula race car racing design and production to achieve a higher performance of the car.”

3D printing key parts of the race car

The application of 3D printing technology in the racing industry is well established. A successful car must have high precision, be lightweight, and have exceptional mechanical properties. The advantages of 3D printing technology will enhance the performance of the car by lowering the weight and improving the design performance. Farsoon and Long Science and Technology racing team have collaborated to redesign these prototypes for analysis while striving to achieve the best results to win on race day.

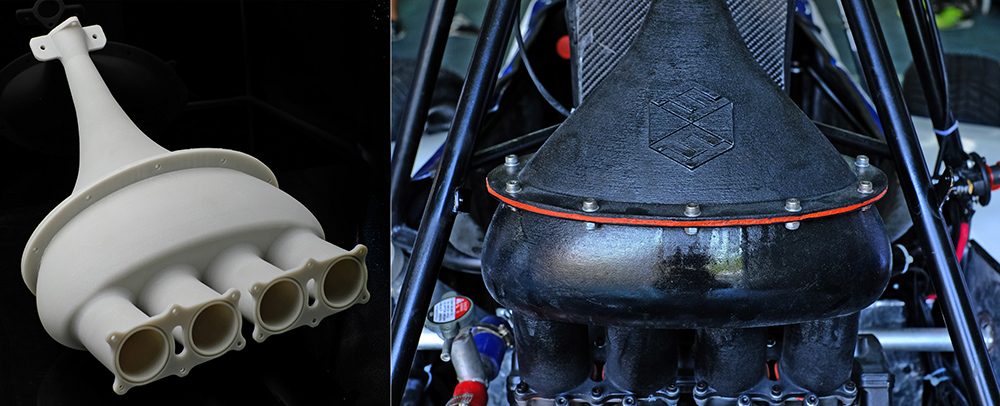

Because the use of traditional manufacturing techniques can be difficult or costly, the FNX-17 racing efforts have modified some of the more complex race car components to be optimized for 3D printing using Farsoon technology. Components, such as the exhaust system of the two-in-one interface, stabilization chamber, intake manifold, steering wheel, suspension and steering system support structure, and aerodynamic kit support structure were all 3D printed to achieve the perfect assembly, high strength and other design requirements.

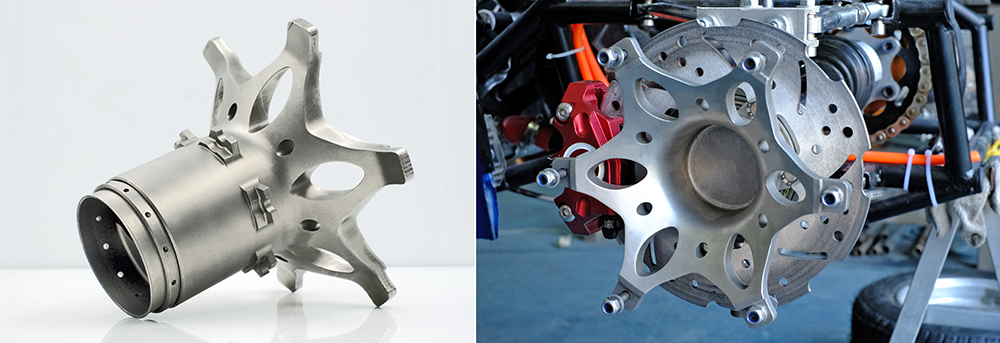

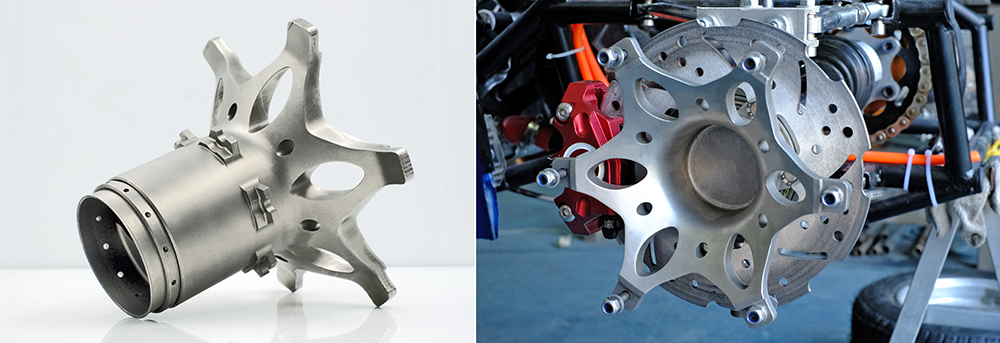

Front and rear hub integration

Material: Stainless Steel

The hub is a cylindrical metal part that connects the wheel to the car while supporting the vehicle’s weight. Any reduction in weight reduces the rotating mass, it’s this reduction in mass that allows the race car to accelerate and decelerate faster.

Front and rear Column

Material: Titanium alloy

Traditionally manufactured with CNC machining, the front and rear column requires a high material removal rate of up to 94%; Still the final product turns out heavy. Thanks to Farsoon’s Metal AM technology, the part is optimized with improved functional design and additively produced using Titanium alloy. The final column is light-weight of only 478 grams, achieved 44% reduction compared to the conventional processed part.

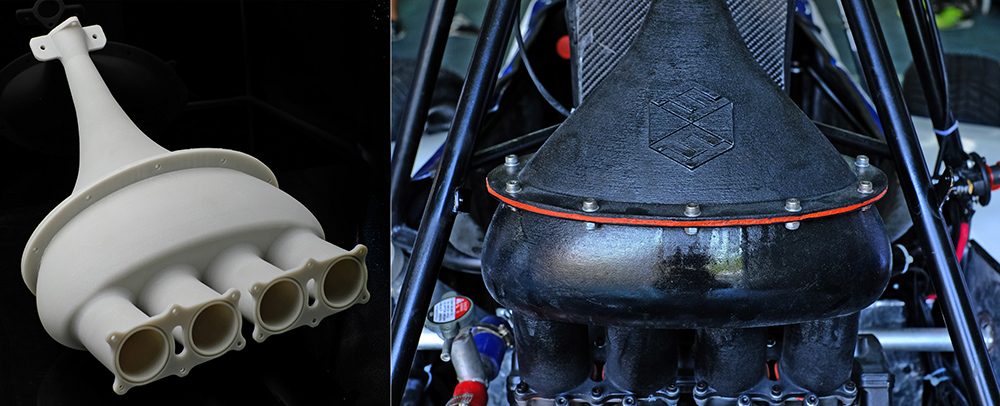

Air intake assembly

Material: Glass Bead reinforced PA12

The nylon 3D printed air intake chamber effectively avoids the limitations of traditional processing technology while aiding in the lightweight, durability, and additional requirements of the race car.

Fuel injection bearing

Material: Aluminum alloy

Traditional manufactured & 3D printing fuel injection bearings

The design of the support structure and the wall thickness was modified to be made using metal 3D printing where strength can be retained and the weight reduced from the original 948g reduced to 397g, a weight loss of 58.12%.

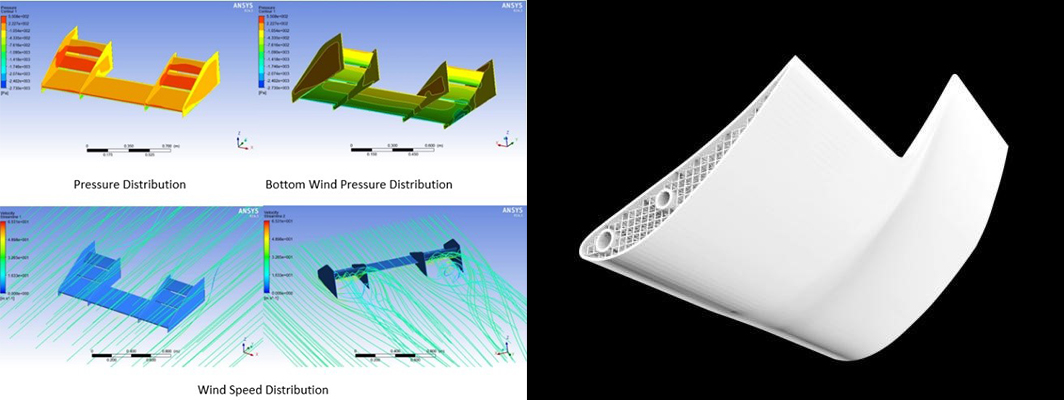

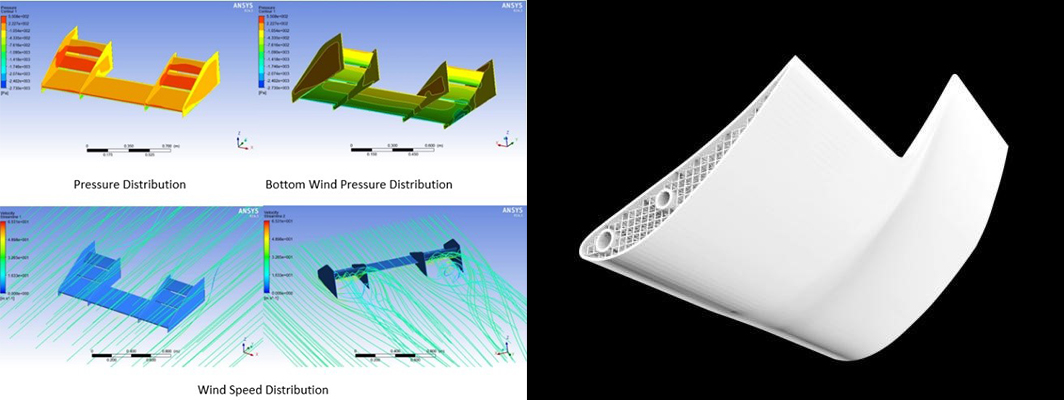

Empty sets of front wing / tail

Material: PA12

The aerodynamics kit provides a significant lift for high-speed race cars, helping increase the grip and traction. While traditional manufacturing methods resulted in poor precision and heavier weight the 3D printing truss structure flaps effectively avoids these defects, providing the part with aesthetics, high-performance, and additional advantages.