As industries continue to evolve, molds play a critical role in sectors like automotive, electronics, aerospace, and medical devices, where up to 80% of components rely on mold production. Metal 3D printing is now leading the way in reshaping the traditional tooling industry, offering new opportunities in applications such as injection molding and die casting. This technology is rapidly unlocking exciting potential by boosting efficiency, reducing lead times, and enhancing design flexibility in mold manufacturing.

Figure 1: Kiben3D metal 3D printing factory with Farsoon FS200M systems. Image courtesy: Kiben3D

Kiben3D Technology is one of China’s pioneering teams in metal 3D printing for molds. With 14 years of experience in industrial 3D printing—8 years dedicated to innovative solutions like conformal cooling and exhaust systems, Kiben3D is at the forefront of advanced mold manufacturing. Currently, Kiben3D operates a fleet of Farsoon FS200M metal 3D printers, enabling high-volume production of injection and die-casting molds.

“Metal 3D printing, known for its precision, flexibility, efficiency, and sustainability, has proven to streamline the production cycles of injection molding and die casting while greatly enhancing product quality. This technology is becoming an essential driver of productivity in the mold industry and is poised to transform traditional manufacturing processes.” Said Mr. Zhang Lei, General Manager of Kiben3D.

Since its founding, Kiben3D has helped over 600 leading manufacturers worldwide reduce costs and improve efficiency using 3D printing technology. Kiben3D has also spearheaded the drafting of key industry standards in China, including the Conformal Cooling Water Channel Design and Maraging Steel Process Specifications for additive manufacturing. With its professional services, consistent quality, and exceptional cost-effectiveness, Kiben3D is generously sharing its unique industry insights and innovative collaboration with Farsoon.

Figure 2: Kiben3D metal 3D printed injection mold insert for packaging. Image courtesy: Kiben3D

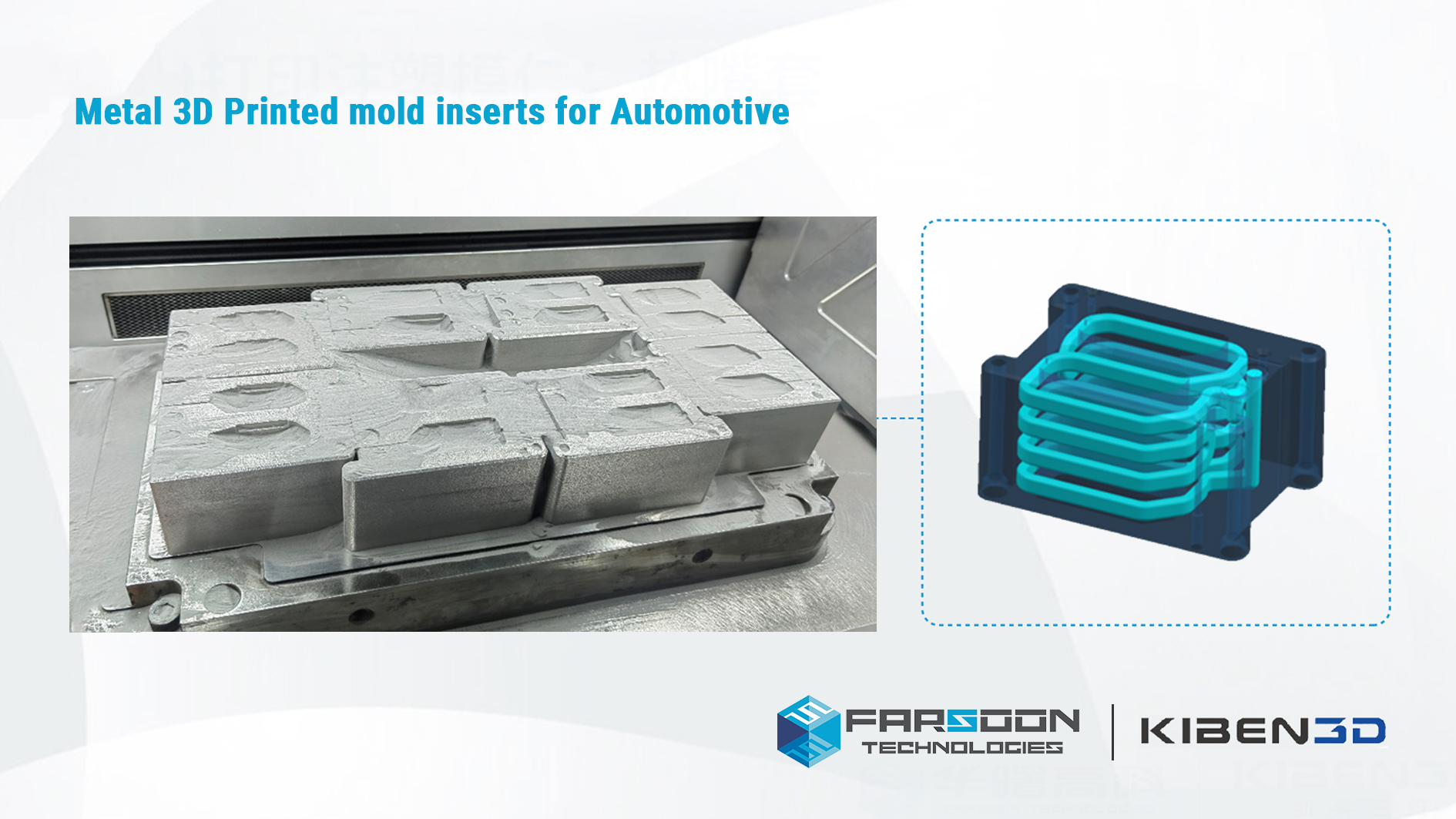

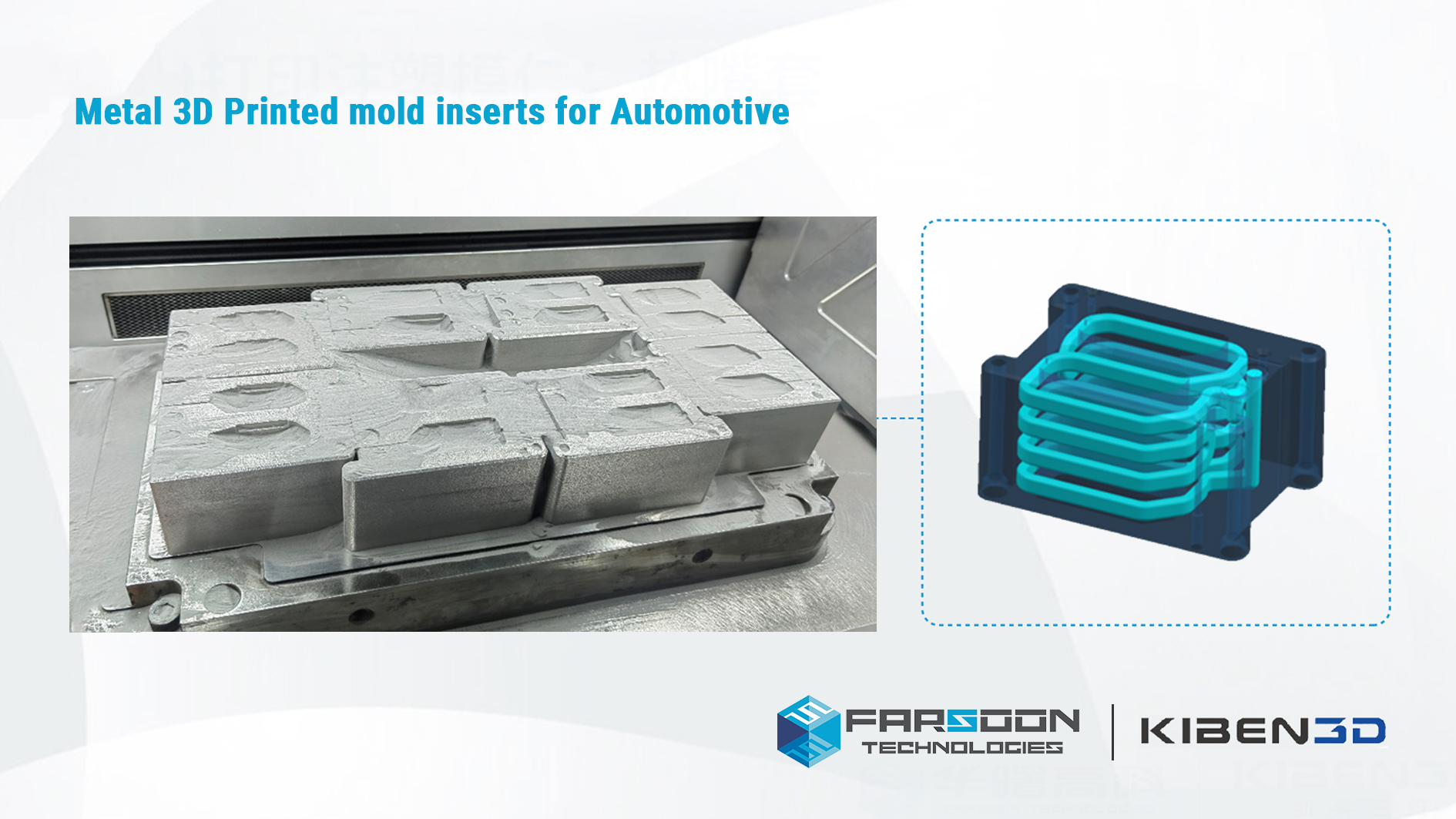

Figure 3: Kiben3D metal 3D printed injection mold insert for automotive. Image courtesy: Kiben3D

Figure 4: Kiben3D metal 3D printed injection mold insert for bottle cap. Image courtesy: Kiben3D

01 Which tooling designs are most suited for metal 3D printing?

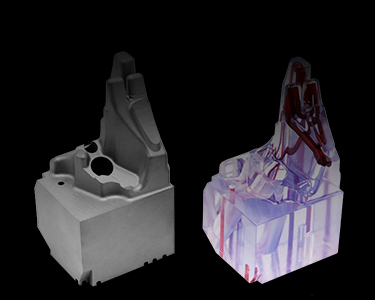

According to Mr. Zhang, metal additive manufacturing can greatly enhance the cooling efficiency of most injection and die-casting molds. However, due to cost and lead time considerations, it is especially well-suited for structurally complex components like inserts and mold cores featuring conformal cooling designs, such as sprue bushings, angled ejector pins, core backing plates, front and rear mold inserts, and sliders.

Additionally, metal 3D printing offers superior dimensional accuracy compared to traditional methods. It also addresses common quality issues such as gate burns, flow lines, weld marks, and trapped air, providing a more effective solution for these challenges through advanced 3D printing technology.

02 What are the typical post-processing of the metal 3D printed molds?

According to Kiben3D, metal 3D printed molds are typically considered rough parts that require additional finishing work. The as-printed molds have a dimensional accuracy of ±0.2mm and a surface roughness of Ra8-12. To prepare for post-processing, a 0.8mm allowance is included during printing. The finishing workflow of 3D printed molds can follow the same practices in traditional maraging steel processing.

Currently, Farson as-printed metal 3D molds can achieve nearly 100% part density and a polishing grade of A2 or higher after post-processing, meeting the needs of most molds, including those for cosmetic packaging and transparent containers. For parts requiring even higher polishing standards, such as A1 grade or above, specialized process parameters are developed in-house to fulfill specific application requirements.

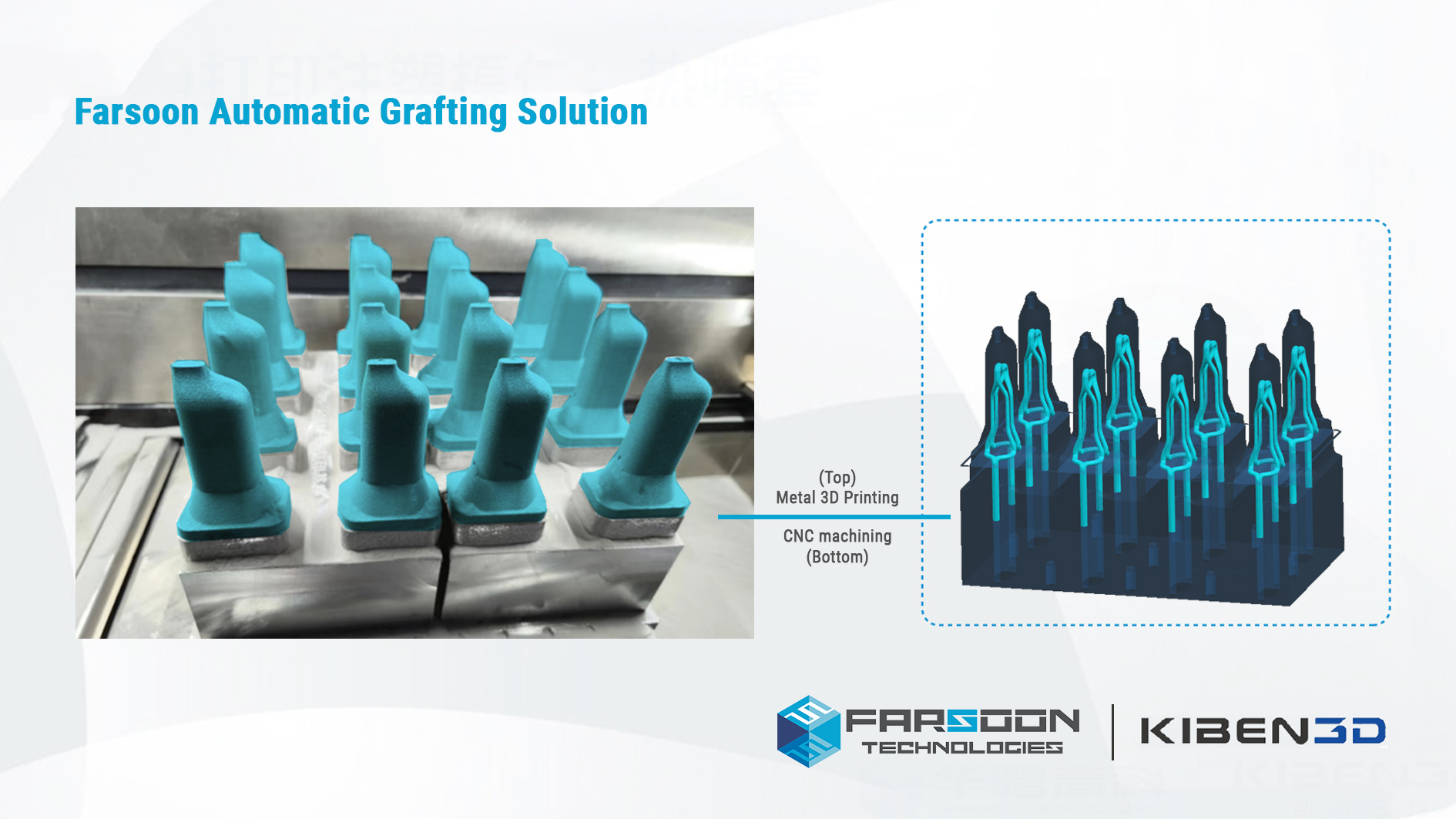

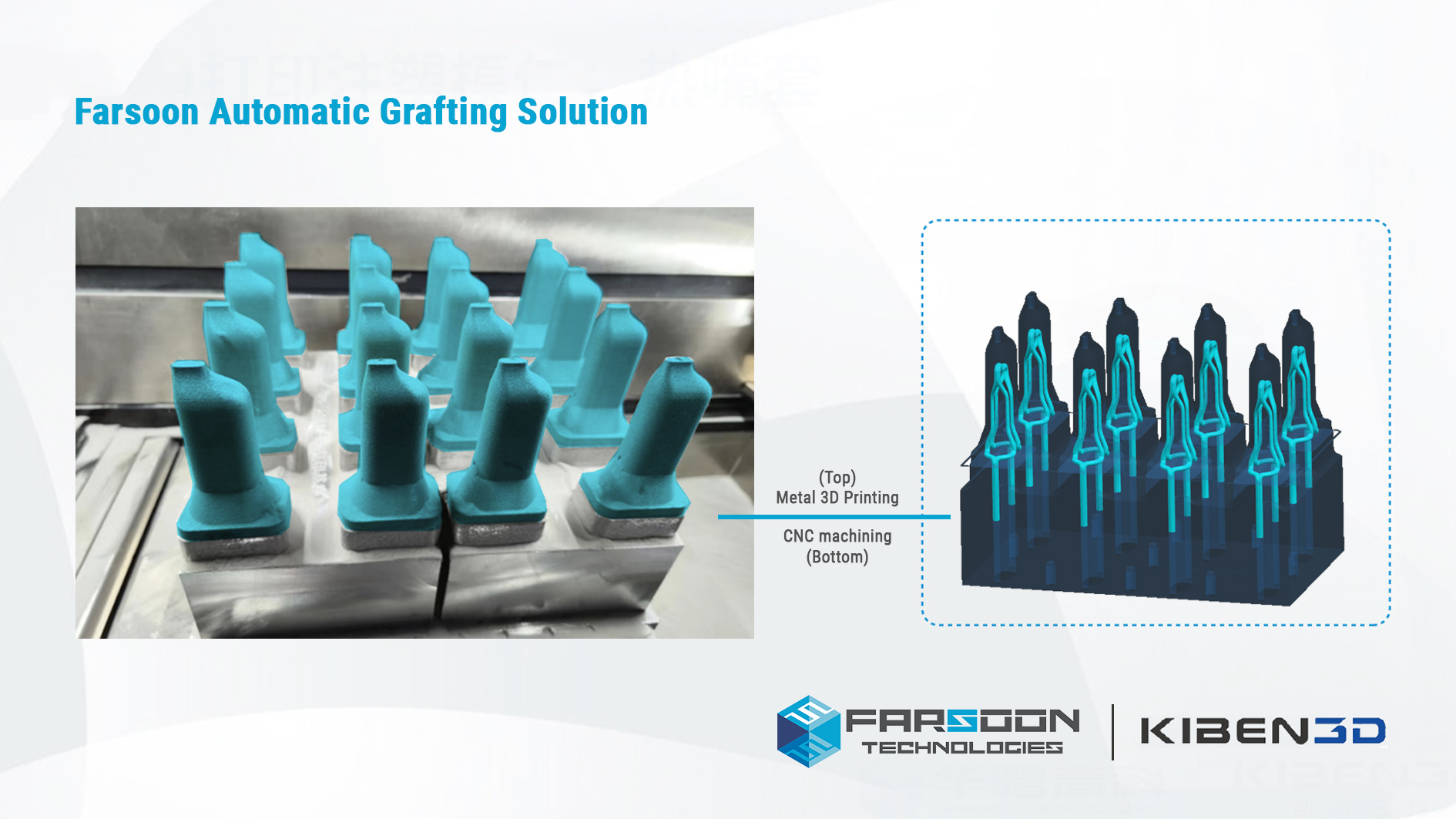

Figure 5: Automatic grafting solutions integrating CNC and metal 3D printing. Image courtesy: Kiben3D

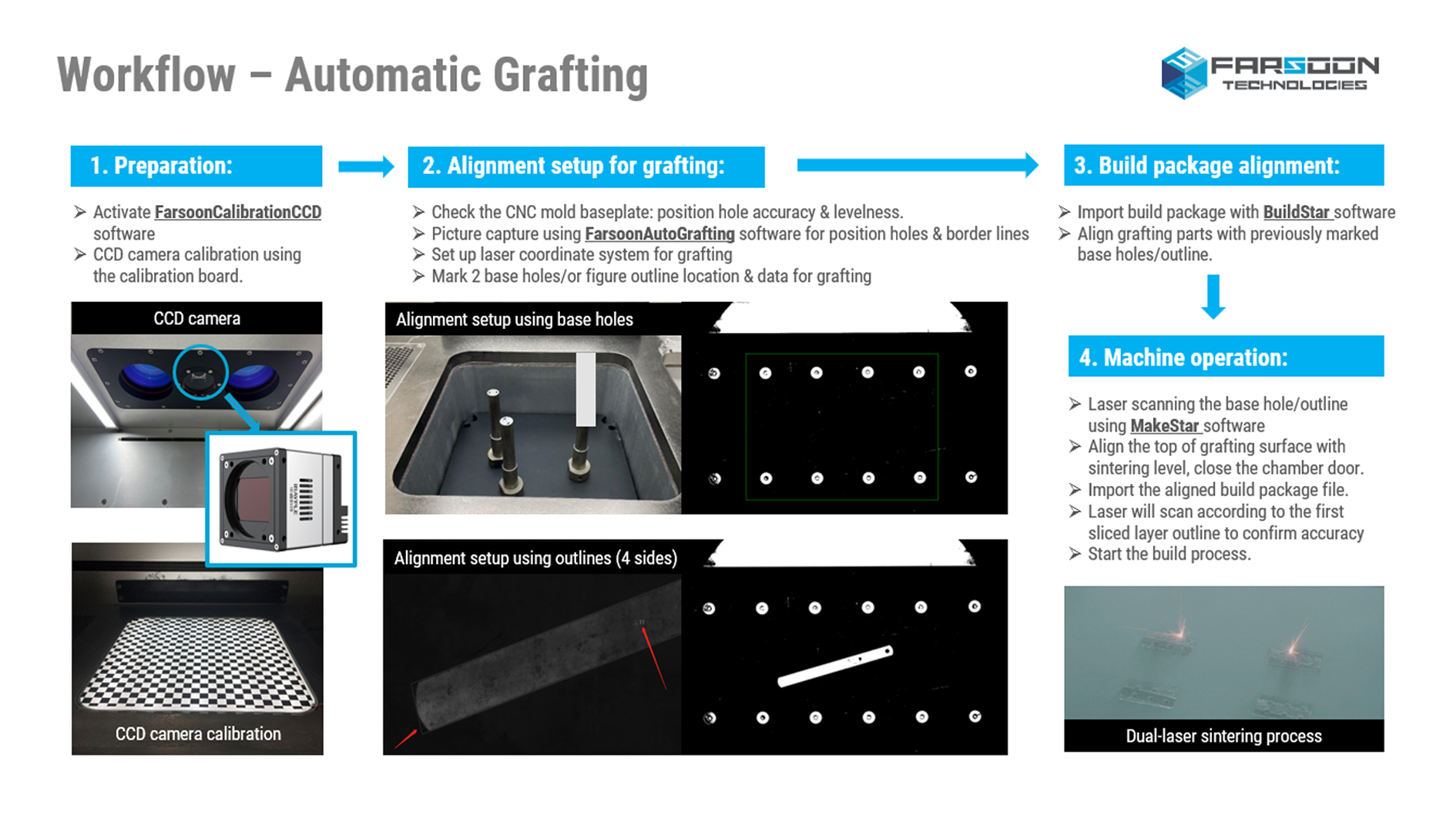

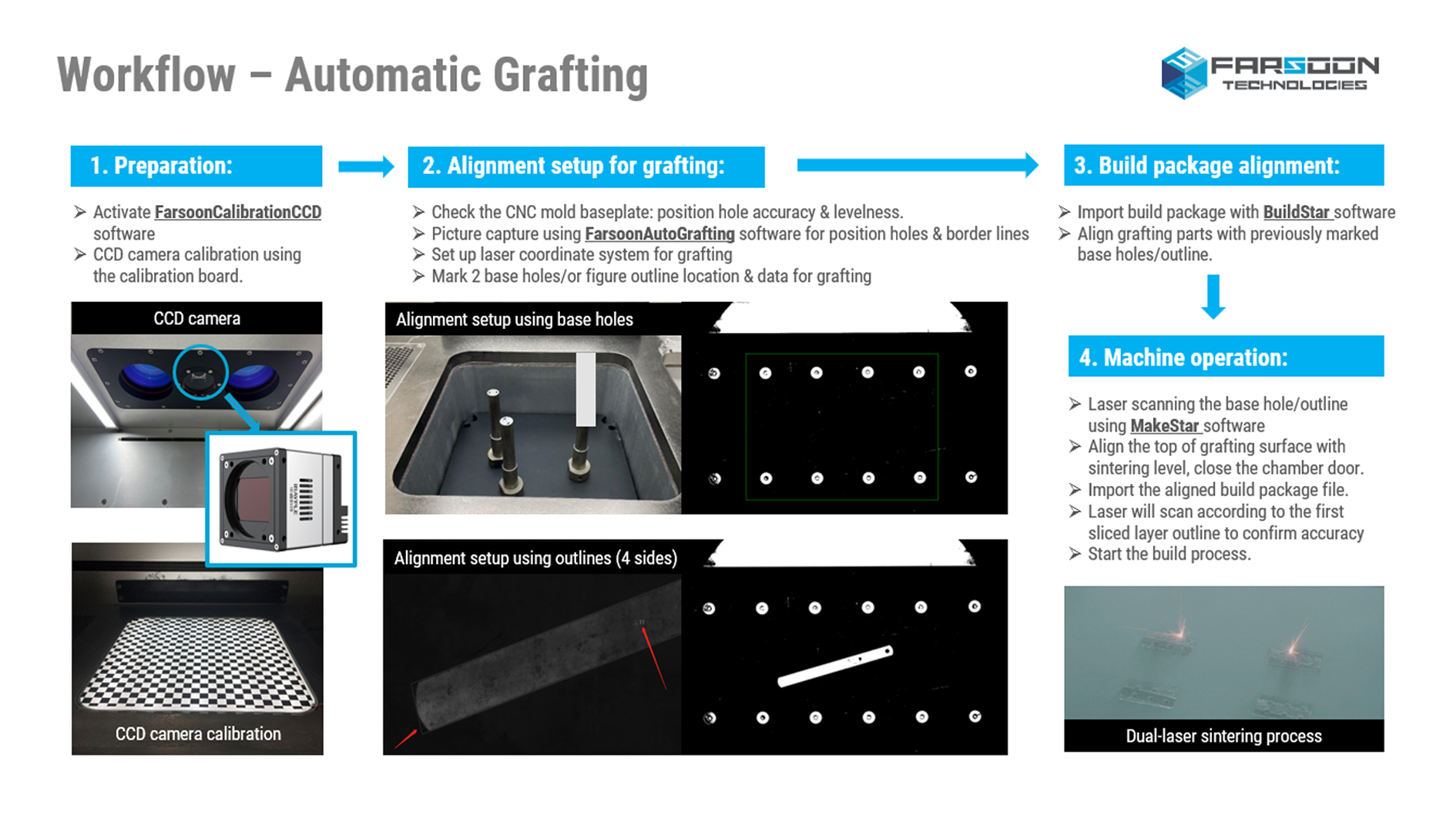

Figure 6: Automatic grafting solutions workflow. Image courtesy: Farsoon

03 How to achieve the best quality and productivity using metal 3D printing?

As early as 2019, Farsoon began collaborating with industry partners to explore the integration of two key processes—CNC machining and metal 3D printing. The base section can be machined using traditional methods, while additive manufacturing continues to build on top of the machined base, creating intricate mold features with precision. To enhance the speed and precision of transitioning between these processes, an advanced automatic grafting solution was introduced.

The process is straightforward:

1. Auto-grafting: Set up the 3D printing laser coordinate system for grafting and define the CNC base outlines for metal 3D printing.

2. Build Preparation: Import the build package and align the grafting parts with the previously marked baselines.

3. Machine Operation: Perform a laser scan of the baselines to ensure alignment between the grafting surface and the sintering level.

By using Farsoon’s automatic grafting, the positioning accuracy can reach up to 0.05mm, ensuring seamless structural integration without cracks or leaks. Today, over 70% of Kiben3D’s tooling products utilize automatic grafting technology, enabling the production of high-quality molds with reduced costs and faster lead times.

04 Cost of metal 3D printing in molds?

While the initial investment for metal 3D printing can be higher, its advantages in enhancing part quality, reducing production time, and minimizing waste make it a cost-effective solution for complex tooling needs. In rapid conformal cooling processes, de-molding time can be reduced by 20-40% per cycle, leading to higher production yields and lower costs per product. The cost of mold printing is mainly influenced by the complexity of the design, part volume, structure, and processing time. As technology advances, the application of metal 3D printing in injection mold manufacturing is expected to become more widespread.

To meet the demands of the mold industry, Farsoon Technologies has developed a comprehensive solution that integrates additive manufacturing equipment, materials, software, processes, and services. Supported by a dedicated process team, Farsoon helps users achieve industrial-scale production. For inquiries, customers are encouraged to contact: globalinfo@farsoon.com.

About Kiben3D:

With over ten years’ expertise in additive manufacturing industry, Kiben3D team is dedicated to provide high value-added 3D printing solutions for industrial users. The company’s main business focuses on SLM (Selective Laser Melting) metal 3D printing for conformal cooling and exhaust inserts application services. Customers interested in application development and product manufacturing are welcome to contact: allen.zhang@kiben3d.com.cn