The 2022 Beijing Winter Olympics draw to a close on last Sunday, with Chinese Short Track Speed Skating team cemented their new legacy with 2 gold medals and a record-setting performance in the 500m. Being one of the three skating disciplines at the Winter Olympics alongside Figure Skating and Speed Skating, Short Track Speed Skating evolves higher level of competitiveness of positioning in a shorter distance. High quality skate blades, are the essential equipment in assuring the best performance for the skaters.

In early 2021, Farsoon Technologies signed a collaboration agreement with the Chinese Olympic Committee to develop the new generation skate blades for the athletes. Taking the unique advantage of the additive manufacturing, the brand-new ice skate blades are produced with the innovative AlMgSc alloy material, featuring light-weight, improved strength and customized design for comprehensive performance.

Material Innovation with High-performance AlMgSc alloy

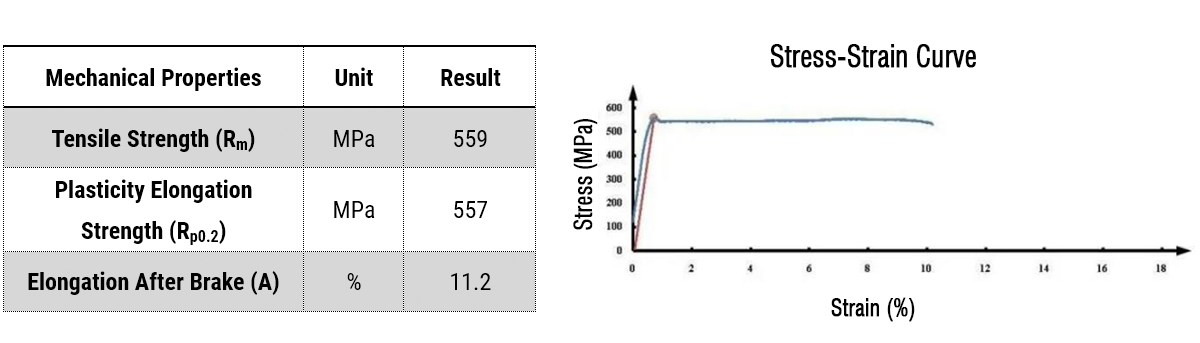

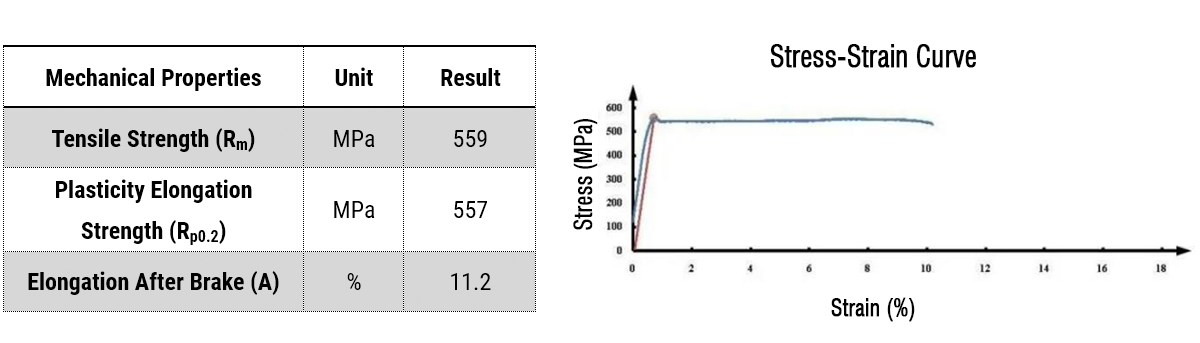

The skate blades are typically made of tempered carbon steel with chrome coasting or aluminum for a reduced weight. Developed from the traditional AlMg alloy, the AlMgSc (aluminum-magnesium-scandium) alloy is a new generation material customized for structural parts used in aerospace and automotive industries; the material features higher strength, excellent plasticity, and high temperature resistance (250°C).

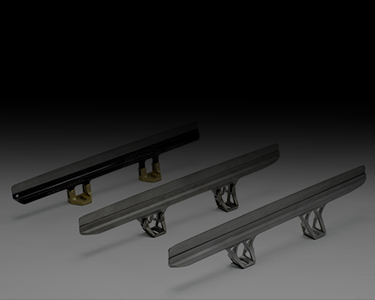

Figure 1: Design iteration process: skate blades featuring light-weight and topology optimization. Image Courtesy: Farsoon Technologies

Thanks to the truly open Farsoon metal systems, Farsoon R&D team is able to fine-tuned the processing parameters of AlMgSc alloy and tested the mechanical properties such as strength, toughness, and fatigue. After a series of iterations, AlMgSc blades are additively produced with Farsoon’s metal laser sintering system FS421M with the best optimized parameters; the performance of the AlMgSc blades offers increased performance of lateral and tangential strength of the blades during the complex and rapid movements, compared to traditional aluminum alloy blades.

Figure 2: Tensile test result. Image Courtesy: Farsoon Technologies

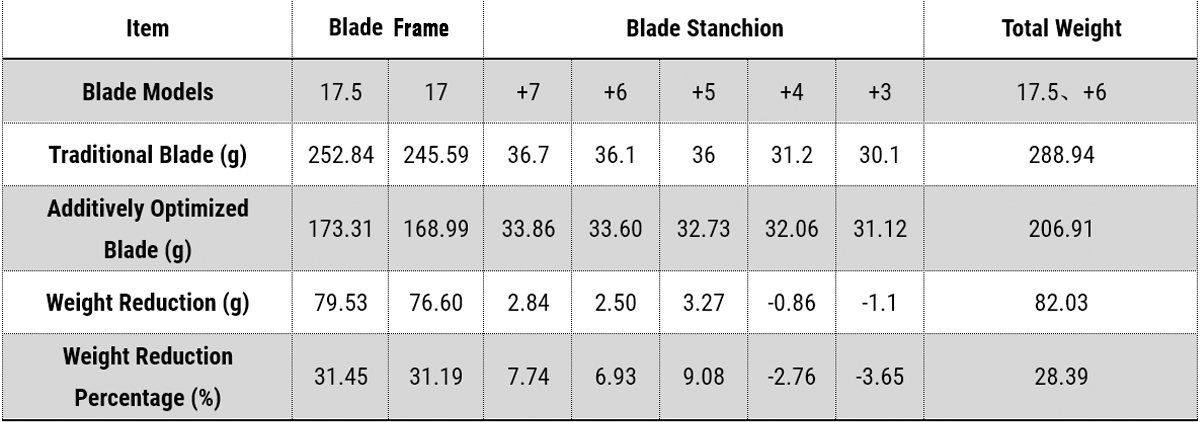

Topology optimization achieves lightweight & streamlined design

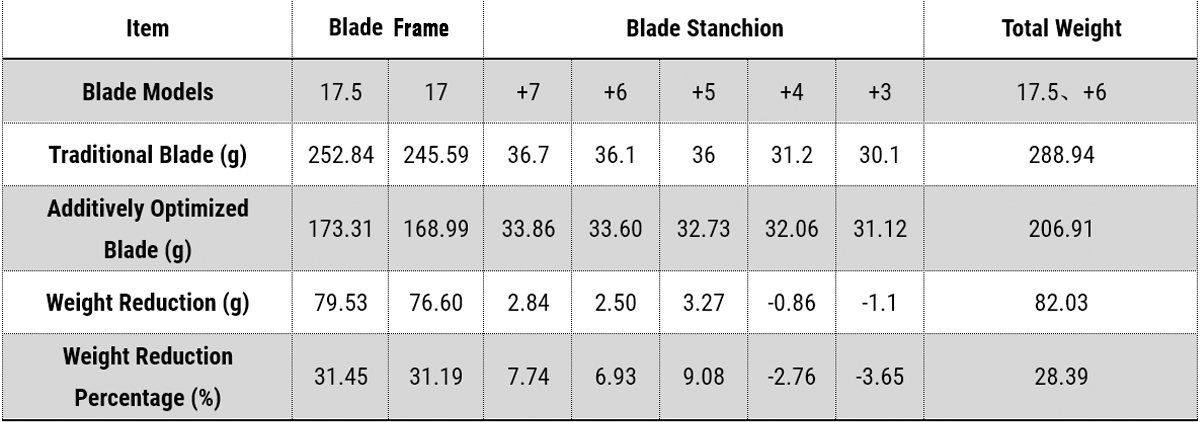

At the beginning of this project, a series of dynamic data of each skater are collected for analyzing the stress on the blades and stanchions during the starting, speeding, relays and turns. According to the data, Farsoon application R&D team conducted a variety of complex “design-build-test” topology optimization on the blade design for the best streamlined geometry, with a significant weight reduction over 20% compared with the traditional blade. The new designs also meet the requirements for quick installation, positioning and processing of the blades.

Figure 3: The speed skating technician measures the radian of Farsoon’s 3D printed blades. Image Courtesy: Farsoon Technologies

Figure 4: Blades weight comparison: Traditional vs additive manufacturing. Image Courtesy: Farsoon Technologies

“Farsoon’s 3D printed skate blades showcases better flexibility in use due to the reduced weight, which offers smoother and better ice grip at cornering and sharp turns.” A Short Track Speed Skater commented, “During our regular tests under many extreme conditions the optimized blades can successfully withstand the mechanical pressure generated by both intensive starting and fast sliding.”

About Farsoon:

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2017, Farsoon released the first of a new series of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS), and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe. Farsoon is committed to developing AM towards its true manufacturing potential and providing customers with best-in-class systems, materials, software, applications and services. Learn more: www.farsoon.com

DOWNLOAD SUCCESS STORY