Mr. Chen Shaocheng, the founder and general manager of YZH Product Development, and his team have been working to bring customer’s inventions to life for over a decade. YZH works with design professionals, inventors, hobbyists as well as large industrial manufacturers to develop their creative ideas into viable designer model products that sells around the globe.

In order to provide each customer a personal touch to the design, Mr. Chen adopted SLA technology in early 2010 for product development and rapid prototyping. “Our intention is to work directly and guide customer step by step through the development process to maximize the potential of their ideas. 3D Printing is a very important tool for this process – it helps us in reviewing and decision making through each development phase to move the product closer to reality.” Said Mr. Chen.

However, with the increasing market demand of the electronic designer models like RC cars and mini-drones, YZH has been working on a number of projects that involve intricate details and more complex components which need to be operated in extreme conditions including collision and drops, rather than previously static display. These tests often create structural damage in SLA produced prototypes due to the limit of mechanical properties. In addition, YZH has planning on expand additive manufacturing from rapid prototyping to series production for customized end-use parts. Starting 2018, YZH began looking for new technology to address these challenges.

“Farsoon’s Flight technology caught our attention when it was first introduced during TCT Asia 2019. The high production speed, fine detail resolution (as small as 0.3mm (0.012 inch)), and high manufacturing quality brings many new possibilities to our design and series production, especially for parts with delicate structures, fine surfaces and thin walls,” Says Mr. Chen, “These unique capabilities convinced us to be one of the pioneer users investing in Flight 403P.”

High Resolution, Quality Components

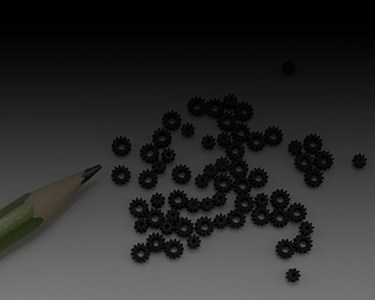

The innovative Flight technology combines the best of SLA and SLS technologies for YZH: high detail resolution and the optimal mechanical performance of plastic powder bed fusion 3D printing. “Now we can series produce a wide range of delicate end-use components and housings with size range from 0.4mm – 25mm (0.016-1 inch) with Farsoon Flight 403P. This advanced technology has brought us huge advantage in developing and produce highly differentiated products to the market.” Says Mr. Chen.

Figure 1: Steering gear components in customized drones with minimum diameter size of 0.4mm (0.016 inch), produced on Flight 403P. Image courtesy: YZH Product Development

Improved Performances

Besides the high-resolution details, parts produced by Farsoon Flight Technology are able to achieve a weight reduction of 20% to 40% compared to those made from SLA technology, while still meeting the designated mechanical properties. The weight reduction of the key components will contribute a significant improvement on the performance of the final product. Also, thanks to the advanced Flight SLS process, complex and delicate parts can now be produced without any supports – this helps reduce the amount of labor required for post processing, and prevent the potential structural or surface damage to the parts during the support removal.

Figure 2: Integrated housing fixtures for Mini-drones, with a consistent thin wall thickness of 0.5mm (0.019 inch), produced on Flight 403P without support, Image courtesy: YZH Product Development

Excellent Yield at Economic Production Cost

Application of the powerful fiber laser on Farsoon’s flagship production system 403P system leads to an industry leading production speed and excellent yield thanks to its expanded build envelope size. “Now we are running the Farsoon machine over 28 days per month, 12+ hours per day with minimum labor required; For small components we can easily add over 10 thousand customized parts in each batch production without the need of any mold-making,” said Mr. Chen, “This new manufacturing tool has brought us the excellent yield and on-demand economy production that we would never imagine.”

Farsoon Flight Technology produced YZH miniature components will be on display at our upcoming in-person global trade shows next month. Customers interested are welcome to visit us at AMUG 2021 in Hilton Orlando at booth 7, and TCT Asia in Shanghai at booth H02 Hall 7.1, or contact us: globalinfo@farsoon.com for more details!

About Flight Technology:

Farsoon’s Flight Technology™ or Fiber Light Technology takes advantage of powerful fiber lasers in place of the standard CO₂ lasers found in standard laser sintering systems. A fiber system is capable of delivering greatly increased power to the powder bed. Due to the more robust and stable nature of a fiber laser system as compared to a CO₂ system Flight Technology™ also provides increased laser longevity which is key when considering ROI for manufacturing applications. In addition, with its increased power and energy absorption characteristics Flight Technology™ will be capable of accessing a much different range of process-able materials and operational flexibility as compared to standard laser sintering systems, which allows for increased freedom for future AM material and application development.

About Farsoon:

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2017, Farsoon released the first of a new series of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS), and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe. Farsoon is committed to developing AM towards its true manufacturing potential and providing customers with best-in-class systems, materials, software, application and services. Learn more: www.farsoon.com

DOWNLOAD SUCCESS STORY