Looking at the bigger picture of the mold-making, additive manufacturing is just one step amongst the many time-consuming processes. The ability to create quality, consistent molds with an accelerated manufacturing stream has become a defining factor to stay in the market competition.

Here is the challenge: when the mold inserts transfer between various different manufacturing equipment, it has to be re-clamped and adjusted to ensure its accuracy in the next process. In traditional machining, the operators can use a variety of fixtures for positioning. Whereas in the 3D printing process, the CNC-machined section has to be re-clamped in position on the base plate, leveled, and centered for 3D printing process. This manual process relies on the operator’s skill and is often limited by the size and complexity of CNC-machined segment, which can take 10-60 minutes per piece of manufacturing objects. When it comes to the large production volume of over 100 pieces per batch, the full positioning process is labor-intensive and time-consuming.

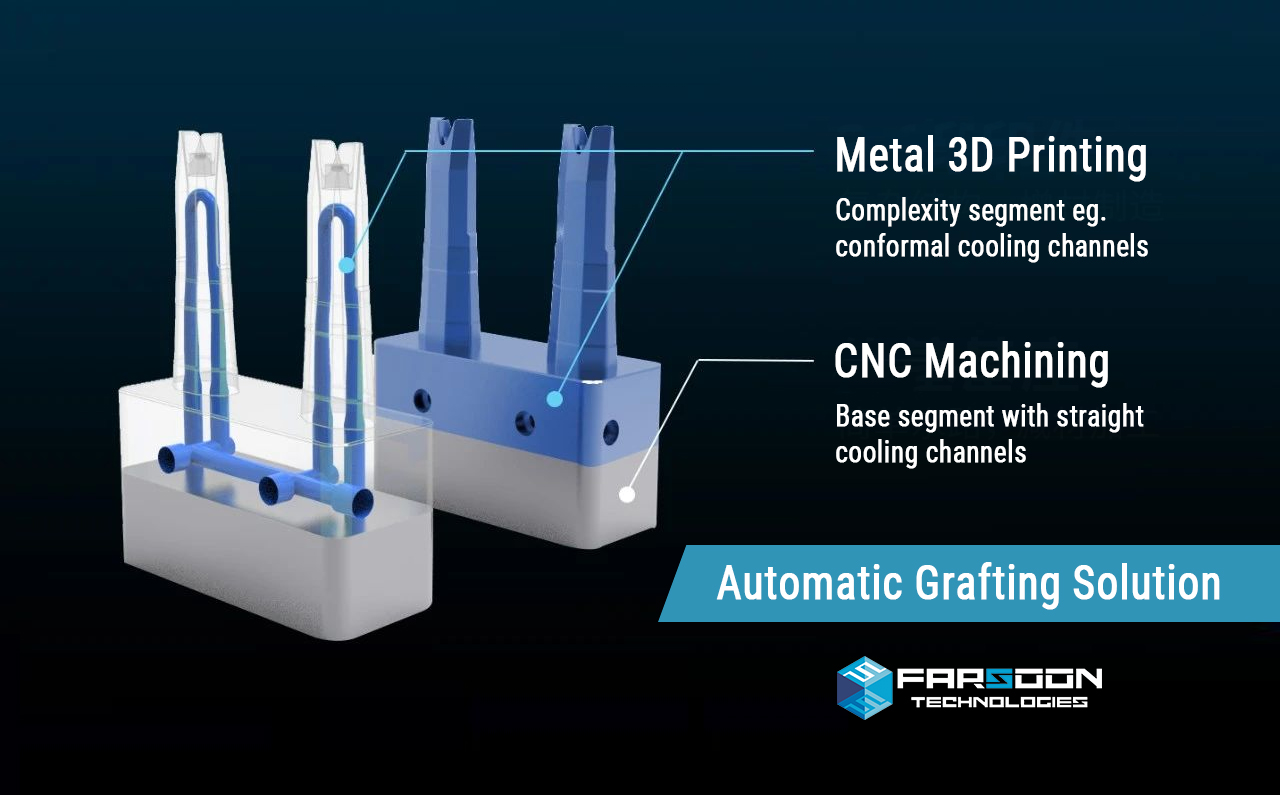

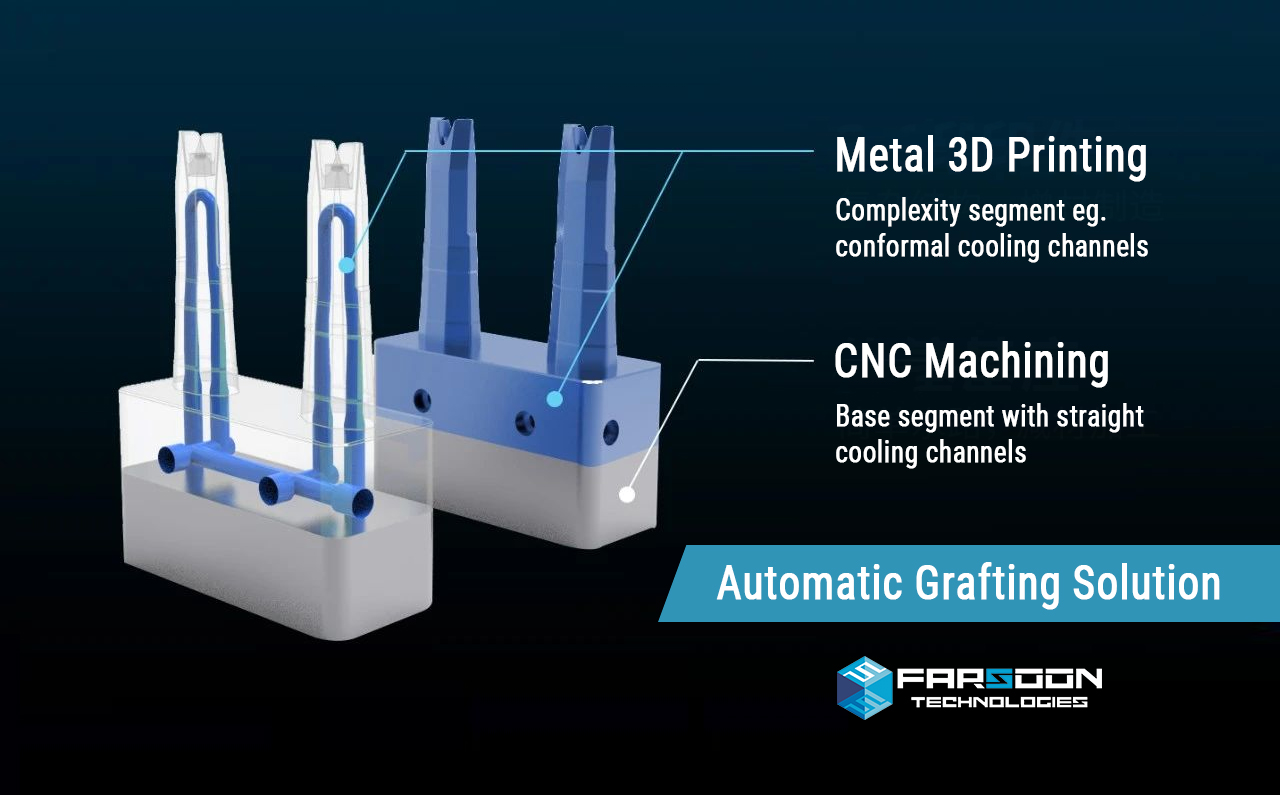

In 2019, Industry innovator Borton Precision partnered with Farsoon and looked into the integration of the two most important processes – CNC machining and metal 3D printing, in pursuit of an advanced grafting solution that can achieve the best manufacturing efficiency and part accuracy.

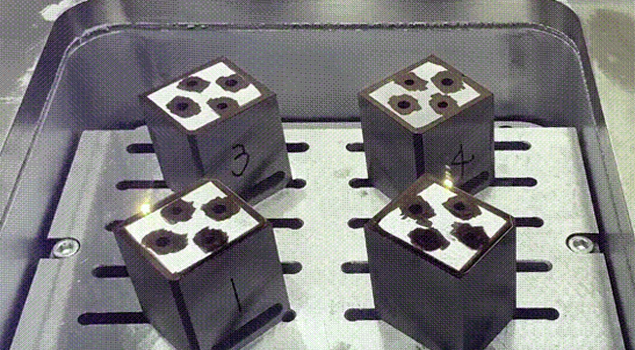

In 2021, with the installation of multiple Farsoon metal platforms FS200M-2 and FS273M-2 at Borton Precision, the innovative grafting solution is introduced to maximize the production efficiency in customized volume-production projects including injection molding, die-casting and fixtures.

The automatic grafting solution package includes:

CCD precision calibration software: FarsoonCalibrationCCD

Automatic grafting software: FarsoonAutoGrafting

Package software: BuildStar (upgraded positioning function)

Build software: MakeStar® (upgraded grafting function)

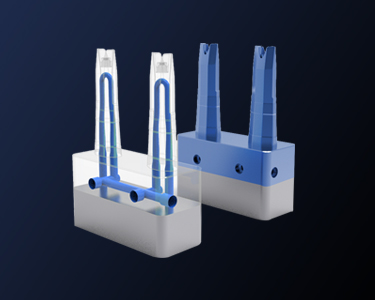

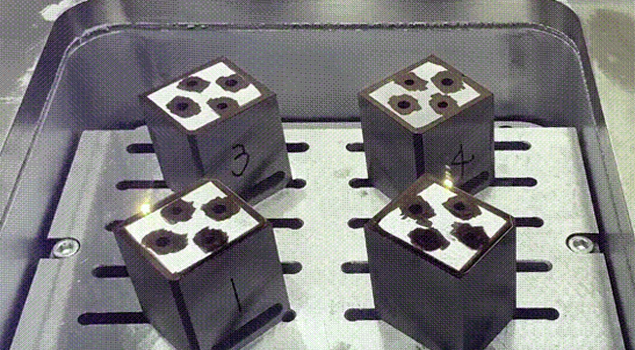

(Figure 1) FS273M-2: The 3D printing process of molds using Farsoon’s automatic grafting solution (Image Courtesy: Borton Precision)

Let’s take a glance of the advantages of the automatic grafting solution:

Improve Productivity & Reduce Cost

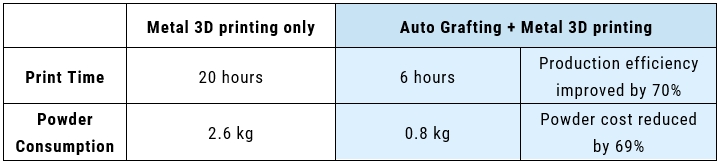

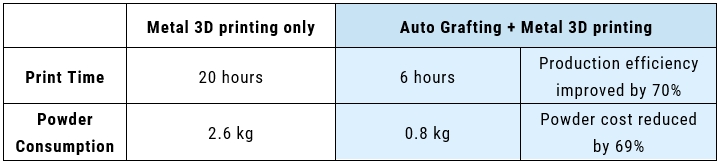

In the world of mold making, manufacturing lead time and cost control are the two major challenges. Take the vaping mold as an example, the application of optimized automatic grafting solution can improve the production efficiency by 70%, reduce powder cost by 69%.

The production efficiency data comparison (Image Courtesy: Borton Precision)

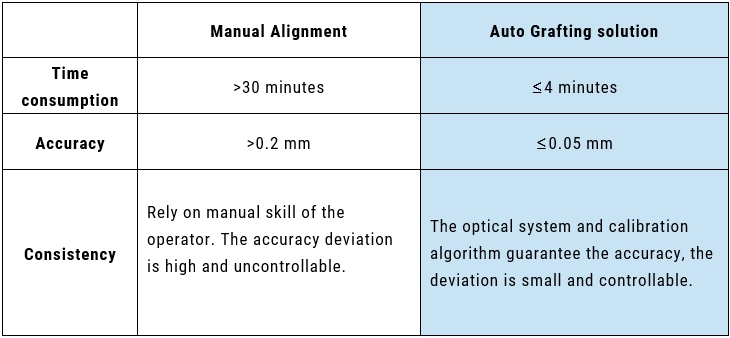

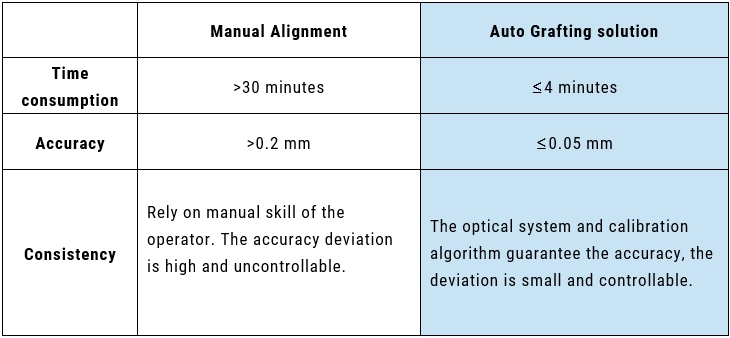

Accuracy & Efficiency

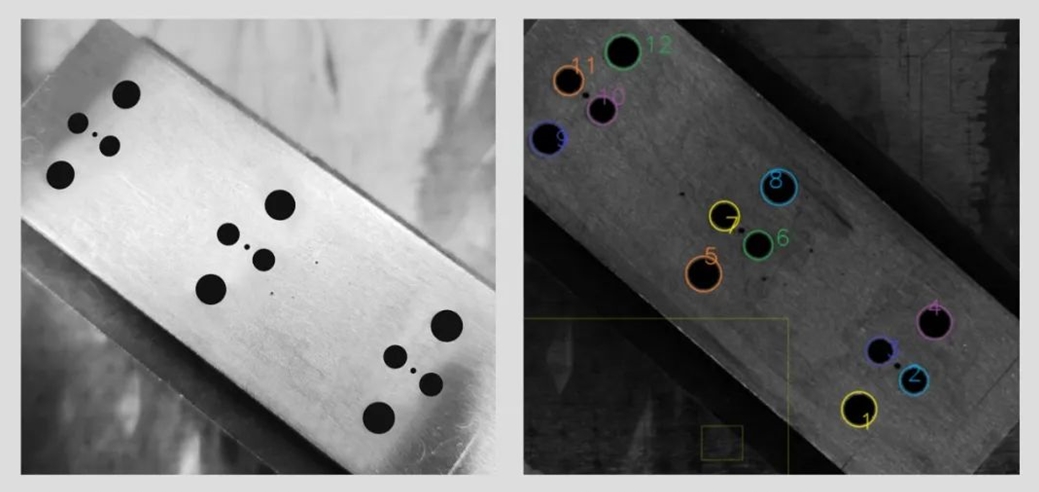

Equipped with high-resolution in-chamber cameras and optimized visual analysis layout, the new automated grafting solution is able to extract the union outline of the bottom section, as well as the internal channel features for best accurate positioning of the 3D printed section. The whole automatic positioning process on Farsoon’s small-medium metal platform only takes few minutes, compared to previously hours of laborious manual alignment work. For advanced designs such as conformal cooling channels, the accuracy tolerance can achieve under 0.05mm, which far exceeds the industry standard of 0.1mm required for a functional mold product.

The production data comparison (Image Courtesy: Borton Precision)

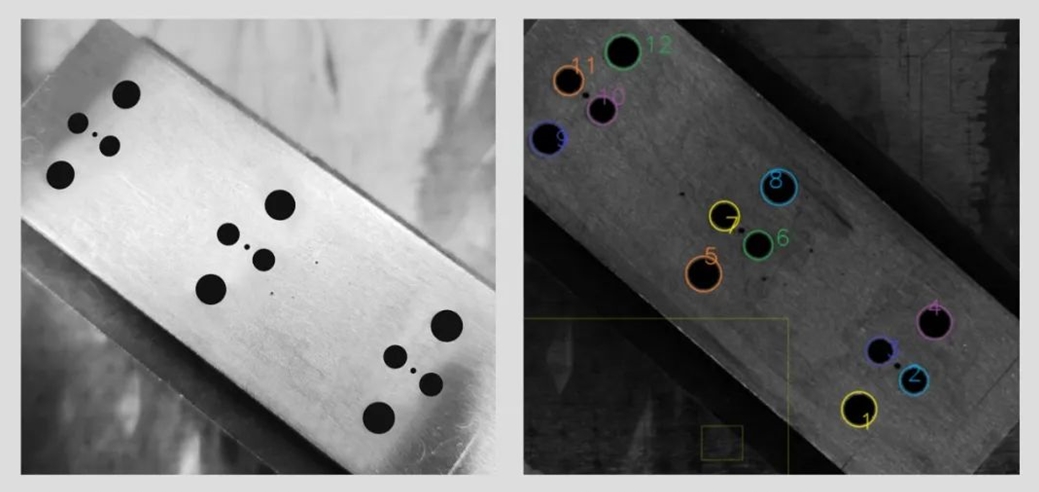

(Figure 2) FarsoonAutoGrafting software is able to extract and define the CNC base outlines for metal 3D printing process. (Image courtesy: Farsoon)

Improved Yield of end-use Product

The new automatic grafting solution is able to optimize the surface quality of conformal cooling channels solving many challenges including adhesion, blockage and fatigue. It enables higher yield of the finished mold product with optimized cooler flow rate and stabilized water pressure.

Farsoon is committed to push true series production of additive manufacturing in the molds & tooling field by co-innovation with industrial partners. Inquires and interested customers in beta-testing of this advanced grafting solution are welcome to contact globalinfo@farsoon.com for more information.

About Farsoon:

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial-level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. Farsoon is committed to developing AM toward its true manufacturing potential and providing customers with best-in-class systems, materials, software, application, and services. On April 17, 2023, Farsoon Technologies Co., Ltd. was publicly listed at the Shanghai Stock Exchange STAR Market through the Initial Public Offering of A-share. The stock code: 688433. For more info please visit: www.farsoon-gl.com.