Huaxiang Group, a privately owned medical 3D printing solution provider founded in 2014, and Dr. Wang Wenjun’s Spinal Surgery team from First Affiliated Hospital of University of South China, recently received category 3 medical device clearance from China’s National Medical Products Administration (refer to as NMPA), for its Porous Spine Fusion Cages produced on Farsoon metal systems — this marks the very first approved orthopedic implants built by metal laser powder bed fusion technology in China.

“This is a ground-breaking day for metal 3D printing in the Chinese medical market.” Said Mr. Li Xinghua, head of marketing from Huaxiang Group: “I’m grateful for joining a such strong team with Dr. Wang and industry additive manufacturing leader Farsoon Technologies for this journey. We are very proud to contribute our effort to future patient-tailored spinal implant surgeries with the application of SLM technology.”

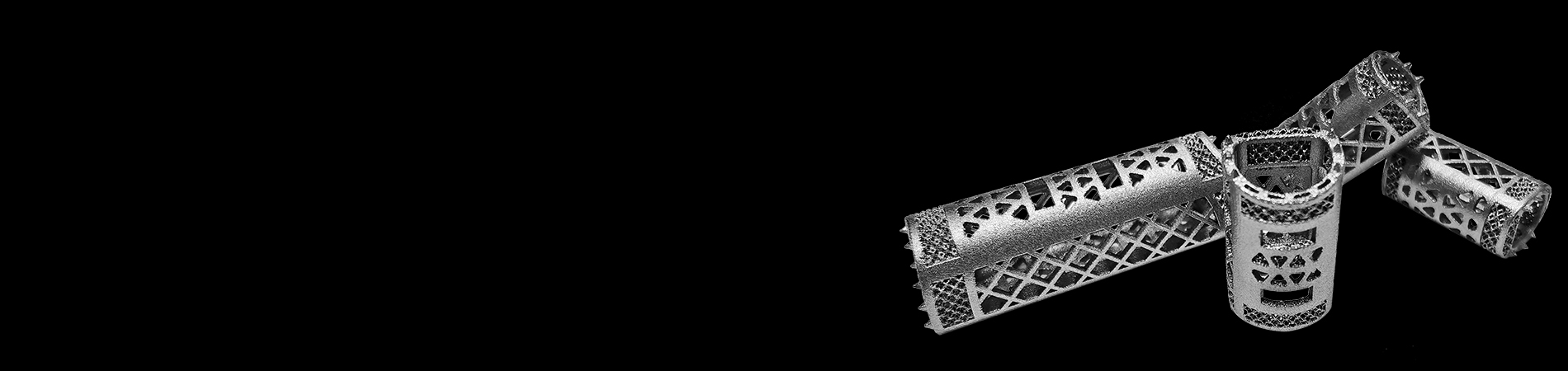

Figure 1: NMPA approved Porous Spinal Fusion Cage 3D printed by Farsoon. Image courtesy: Huaxiang Group.

Compared to traditional trimmed cage and anatomical cage, the 3D printed Porous Spinal Fusion Cage is an advanced solution for spinal conditions including degeneration, fractures, deformities and tuberculosis. Being one of the key medical implant products identified by the 3D Printing Technology Application of Personalized Implant Device project headed by the country’s leading hospitals, research institutes, material manufacturers and 3D printing specialists in the country, the NMPA approved the 3D printed Titanium Spine Fusion Cage showcased a combined knowledge in medical-grade material, additive manufacturing, design software, medical device development & clinical application.

The Spine Fusion Cage portfolio is developed with patent-tailored process from Dr. Wang Wenjun’s Spinal Surgery team for customized volume batches. The development has taken multiple iterations of structural optimization through the years, with comprehensive research over 30 mechanical properties, physical & chemical performance, biological evaluation and cytotoxicity, etc. During the clinical study phase, Dr. Wang’s team has conducted 108 cases in 5 Tertiary A hospitals across the country before it received the clearance from NMPA.

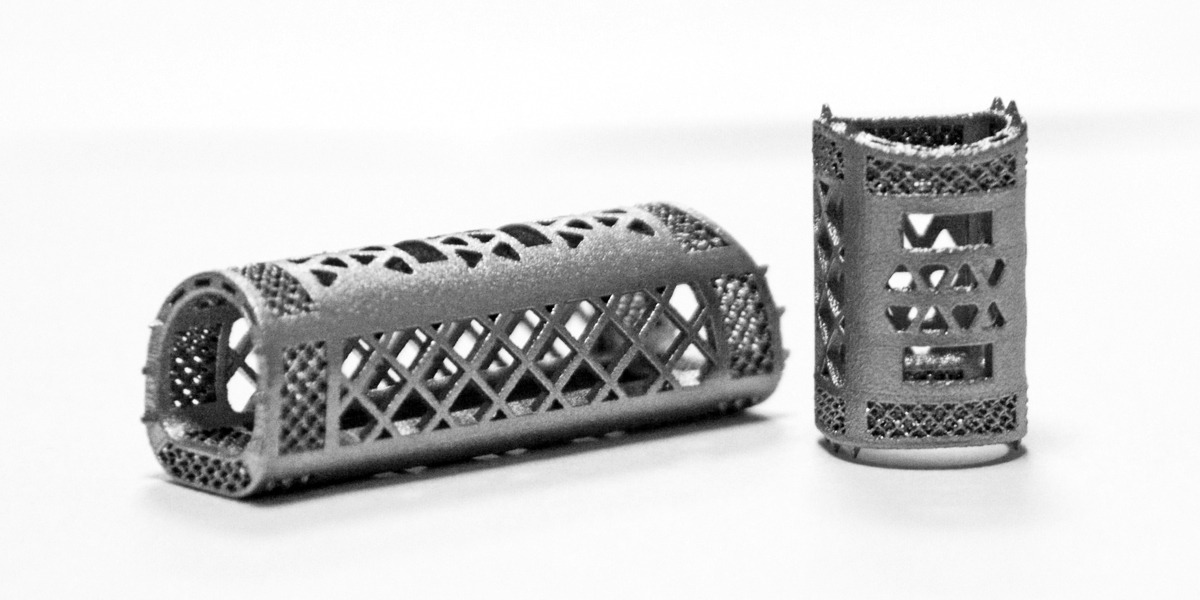

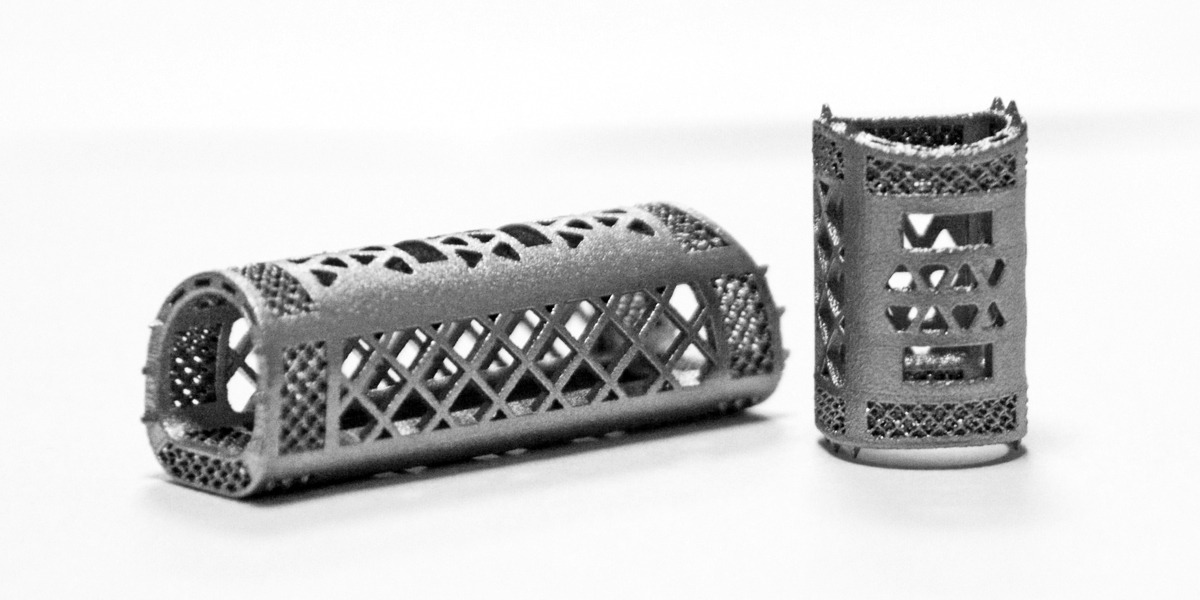

Figure 2 (top left): 3D printed Porous Spinal Fusion Cage portfolio featured with a variety of geometries structures. Image courtesy: Huaxiang Group.

Figure 3 (top right): Huaxiang team conducts Spinal Fusion Cage production on Farsoon FS121M metal machine. Image courtesy: Huaxiang Group.

With the advanced capabilities of metal additive manufacturing, Dr. Wang’s team together with medical additive expert Huaxiang Group, are able to create a unique lattice design similar to the trabecular micro surface structure featuring customizable pore size, porosity and elastic modulus that are close to that of human bones. It helps to reduce the tension of stress, promote bone in growth rate and long-term stability. With substantial input from surgical design and metal 3D printing, unique geometries structures with fully customized anatomical endplates which feature curved angles and expanded contact surface topology are able to deliver the perfect anatomical match for a wide range of complex surgical conditions. The surgeons also benefit from significantly faster “on-demand” development to production cycle for a high-quality, precise product by using Farsoon laser powder bed fusion systems, whereas the conventional multiple-use device usually takes months to manufacture.

Farsoon strives to expand the envelope of additive manufacturing by working with industrial partners and offer highly productive 3D printing solutions in the medical field. During May 26-28th, 2021, Farsoon will be showcasing this Porous Spinal Fusion Cage product at booth H02, Hall 7.1 at TCT Asia located in Shanghai National Convention and Exhibition Center. Inquires and interested customers are welcome to contact globalinfo@farsoon.com for more information.

About the 3D Printing Technology Application of Personalized Implant Device Project:

The 3D Printing Technology Application of Personalized Implant Device project is an initiative supported by the Ministry of Science and Technology in the “13th Five-Year Plan”, led by Shanghai Jiaotong University’s Ninth People’s Hospital, with a strong team consisting of members from the Chinese Academy of Sciences Institute of Metal Research, South China University of Technology, Sichuan University, Xi’an Jiaotong University, Shanghai Institute of Ceramics, Hubei University, Central South University, Farsoon Technologies and Huaxiang Group. The goal of the project is to establish, and extend the application of total 3D printing solutions for advanced medical devices including medical-grade material, 3D printing machines, design software, medical device development & clinical verification and medical supply chains.

About Huaxiang Group:

Huaxiang Group is the industrial leader of medical 3D printing application in China. With an established medical industrial chain including materials research and development, software, additive manufacturing, post processing, etc., Huaxiang Group is ready to offer hospitals and doctors with comprehensive, accurate and efficient industrial grade medical 3D printing solutions.

About Farsoon Technologies:

Farsoon Technologies was founded in China in 2009 and is a supplier of industrial-quality plastic laser sintering and metal laser melting systems. Farsoon has assembled a team of world-class experts in electrical and mechanical engineering, lasers, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diversified company, Farsoon was founded with the clear vision and core objective of creating open platform systems that give the sector the freedom to innovate and expand implementation of additive manufacturing on the global product market.

DOWNLOAD SUCCESS STORY