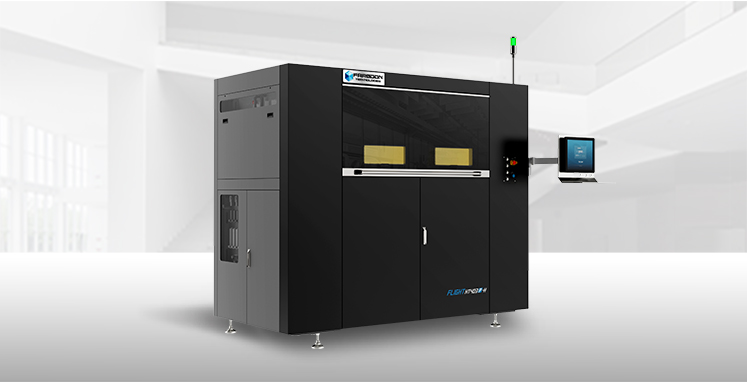

- About Farsoon

Your Industrial

- Products & Solutions

Products + Solutions

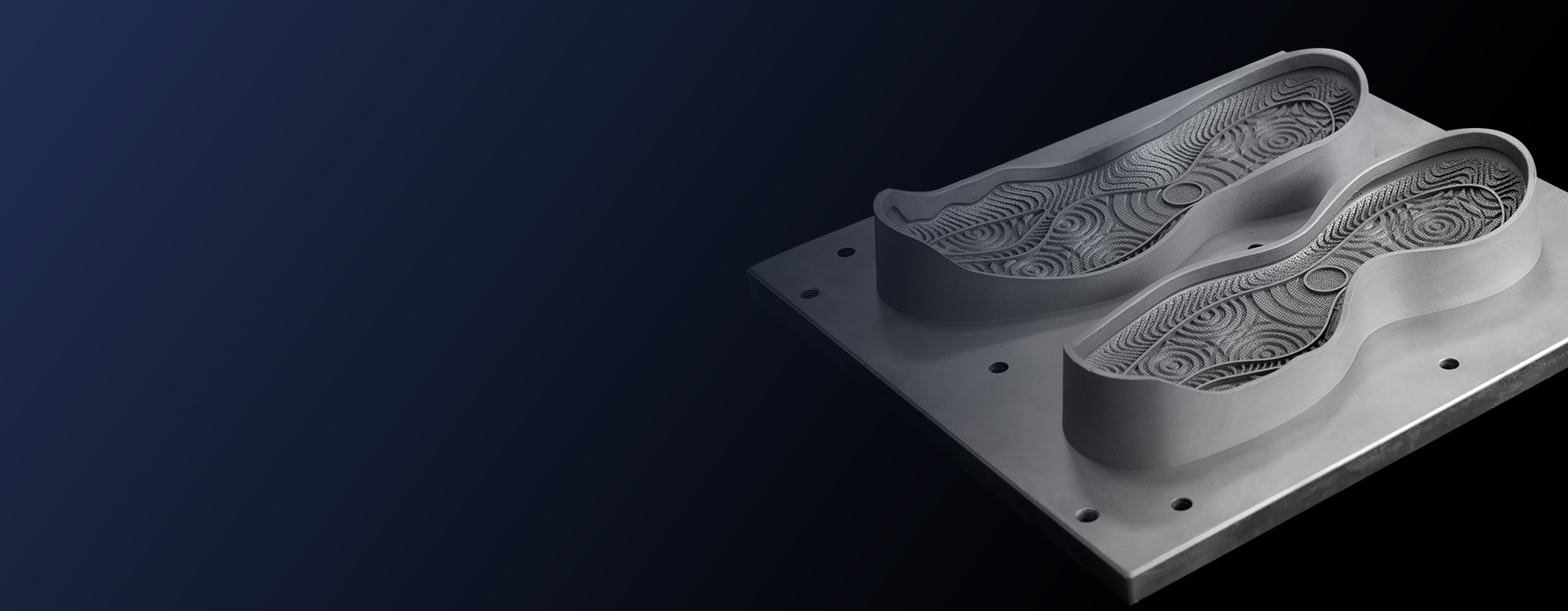

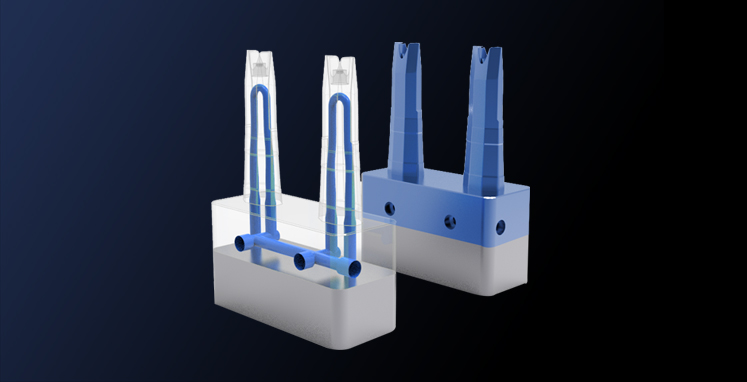

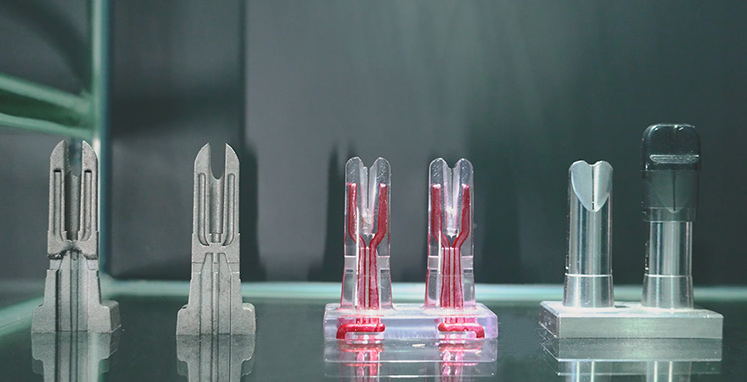

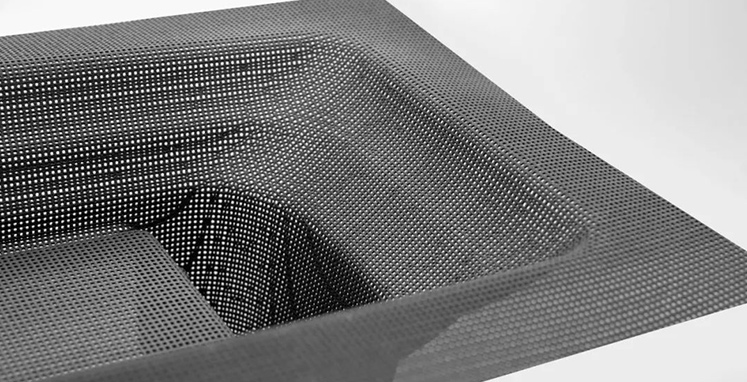

Farsoon offers high-quality AM solutions that can be tailored to your production needs -- including off-the-shelf 3D printers, customized solutions, engineering materials, software systems, customer-centric services and support.

- Success Stories

Innovation. Manufacturing. Together.

Take off with truly open Farsoon AM solution for your industrial production and application innovation. Our extensive product portfolio and customer-centric service will pave the way to your business success.

- News & Media

Company news, events and more.

Stay tuned with our latest innovation in additive manufacturing – new product solutions, industry partnerships, global events, resources and more!