March 17, 2025, Shanghai – Farsoon is proud to announce our latest advancement in industrial metal powder bed fusion technology: Beam Shaping Technology. This innovation represents a significant leap forward in performance, detail, efficiency, and versatility for metal additive manufacturing.

At this year’s TCT Asia, Farsoon is not only showcasing its expertise in large-scale equipment but also emphasizing its commitment to fundamental technological advancements. Driving high-quality, high-volume serial production, Farsoon’s Beam Shaping Technology has been demonstrated across four state-of-the-art metal systems: the FS721M-H-8-CAMS, FS350M-4, FS273M, and FS191M – with each system feature live printing at the event.

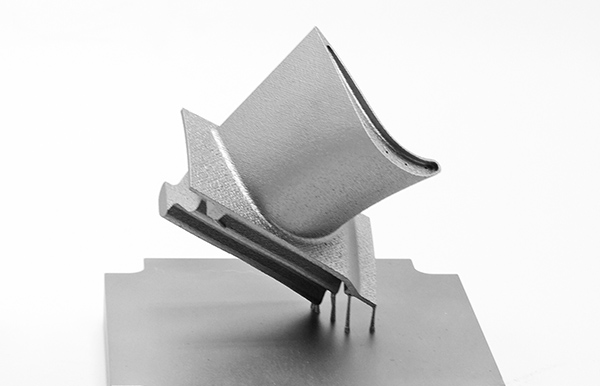

Farsoon’s unique Beam Shaping Technology enables laser spots to be dynamically formed into various shapes, such as ring-shaped, point-ring-shaped, or fully customizable configurations tailored to specific application requirements. When combined with high-power lasers and optimized scanning strategies, this technology significantly enhances printing quality and efficiency for materials like stainless steel, aluminum alloys, and titanium alloys, achieving part densities exceeding 99.95%.

Key Advantages of Farsoon’s Beam Shaping Technology Over Traditional Gaussian Spots:

• Unmatched Printing Speed: Melt pool width increases by 50%-100%, with increased build volume rates by 2.5+ times—without compromising part quality.

• Reduced Spatter: Melt pool spatter (same power & layer thickness) is reduced compared to traditional Gaussian spot, minimizing powder contamination and porosity in built parts.

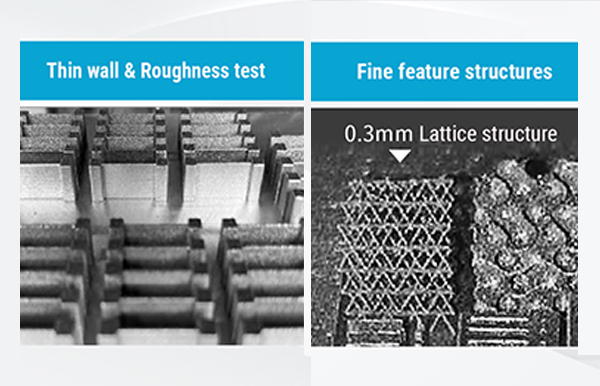

• Exceptional Detail Fabrication: Enables precision manufacturing of intricate features, such as thin wall structures.

• Enhanced Thermal Stability: Lower temperature gradients improve process stability and part consistency.

• Broad Material Compatibility: Ideal for high-thermal conductivity materials, including copper alloys.

Applications Across Industries:

Farsoon’s Beam Shaping Technology is poised to transform industries such as consumer goods, mold manufacturing, 3C electronics, aerospace, and precision casting. Its versatility and performance make it a game-changer for demanding applications.

As Farsoon’s flagship medium-sized metal production system, the FS350M-4 platform equipped with Beam Shaping Technology delivers unparalleled performance for industrial additive manufacturing. Featuring quad 1000-watt lasers and a build volume of 433 x 358 x 400mm, this system is engineered to significantly enhance productivity and manufacturing turnover rates. The integration of Beam Shaping Technology ensures superior print quality, faster build speeds, and exceptional material utilization, making it an ideal solution for high-volume serial production across a wide range of industries.

Looking ahead, Farsoon plans to integrate Beam Shaping Technology into larger metal platforms, including the FS621M, FS811M, and meter-scale systems. Customers interested in exploring this technology or participating in beta programs are invited to visit Farsoon at TCT Asia, Hall 7.1, Booth 7F05, or contact us at globalinfo@farsoon.com.