New to metal additive manufacturing? Let’s start with some quick insight of environmental set up, processes to materials that will help you get started!

1. Inert Gas

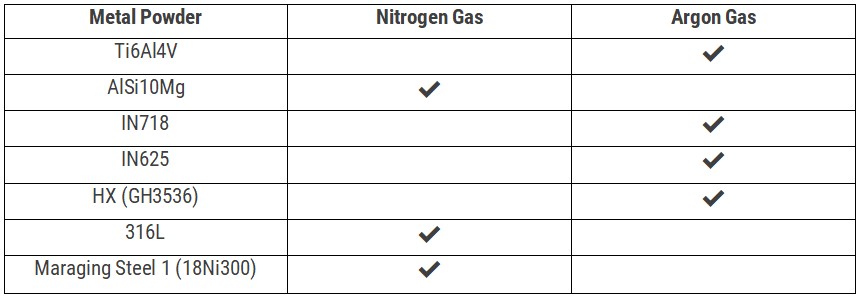

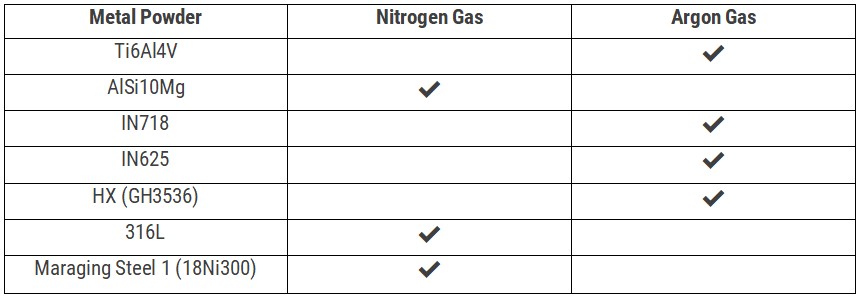

The additive process for powder bed metal requires the protection of an inert gas (nitrogen, argon, etc). The higher the purity of the inert protective gas, the higher the quality of the built parts. Due to the different powder properties and reactivity, different types of inert gases need to be used accordingly. When feasible, it is recommended to use argon as the protective gas due to its purity and inert properties.

The continuity and sufficiency of the gas supply is also key for guaranteeing good part properties. The lack of gas supply may cause a pause during the build process. The workpiece surface will leave traces of shrinkage due to workpiece cooling if the sintering operation cannot be recovered in time.

Types of common metal powder and inert gases to use:

2. Power supply

Metal parts of larger size or bulk volume often take days or weeks to build, during the build time the power requirements of the Metal AM system will reach several kilowatts. It is important that the Metal AM system has a continuous and reliable power supply. If a sudden power failure occurs, the machine shutdown will result in adverse effects on the printing process. If the power failure causes build process data loss, the work piece will be unable to continue resulting in the whole build job being scrapped. Farsoon Metal AM systems have built in features to cope with extreme situations such as sudden power loss, to protect the scanning location upon time and prevent software build data loss. The work piece will be able to continue after the power is recovered.

3. Powders

The quality of the powder directly determines the quality of the print. Confirm the following before printing:

(1) Ensure there is adequate powder in the system, avoid pausing to add more powder.

(2) Adjust powder feed. Not enough powder feed will lead to incomplete surface coverage, and too much powder feed will increase waste. In order to optimize powder utilization, Farsoon has developed the Smart Feed Gain parameter to automatically adjust the feed amount based on the features of each unique part.

(3) Ensure the brand and the chemical composition of the powder meet the required performance standards such as particle size distribution, flowability, oxygen content, sphericity, packing density, hollow powder ratio, etc. Used powder will contain oversize and irregular particles which will require sieving and examination before mixing.

It is essential to keep powder organized when managing multiple material types. The powder should be stored in an airtight, anti-static, and flame-retardant container in a dry, cool, and non-corrosive environment. Powder storage procedures should be provided by the powder supplier. Necessary measures should be taken to prevent powder from being contaminated during use, storage, transportation, sieving, and cleaning.

At Farsoon, we offer an extensive, high-quality metal material portfolio for use with our LPBF systems supplied by industry-leading powder suppliers. Farsoon has developed, tested and qualified a wide range of metal engineering materials optimized for additive manufacturing to ensure the repeatable quality and performance of the produced parts.

For more information, please reach out to us: globalinfo@farsoon.com.