In the evolving landscape of polymer powder bed fusion, one trend stands out: the demand for truly open, industrial-grade 3D printers that can process high-temperature materials. Farsoon is proud to collaborate with leading global experts in material innovation and industrial manufacturing.

Among them is AM-Rauch, a specialized service provider located in Baden-Baden, Germany, renowned for its 12 years’ expertise in utilizing high-performance polymers with Powder Bed Fusion (PBF) technology. AM-Rauch focuses on process parameter development, delivering precision-engineered technical parts in batch series, matching to the stringent demands of medical and manufacturing sectors.

We are excited to announce the successful completion of a beta test of Farsoon’s medium-frame Super-Temperature PBF ST252P system, as well as a customized large-frame Ultra-temperature PBF Flight UT501P system at AM-Rauch. The goal of the beta testing targets high-temperature engineering material process development for new applications, enhancing the capability of prototyping and medium-size series production.

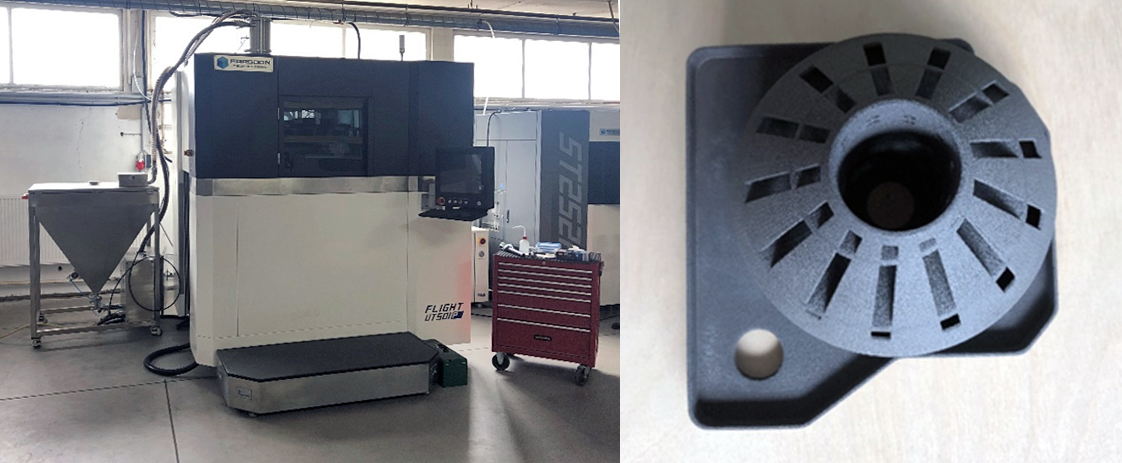

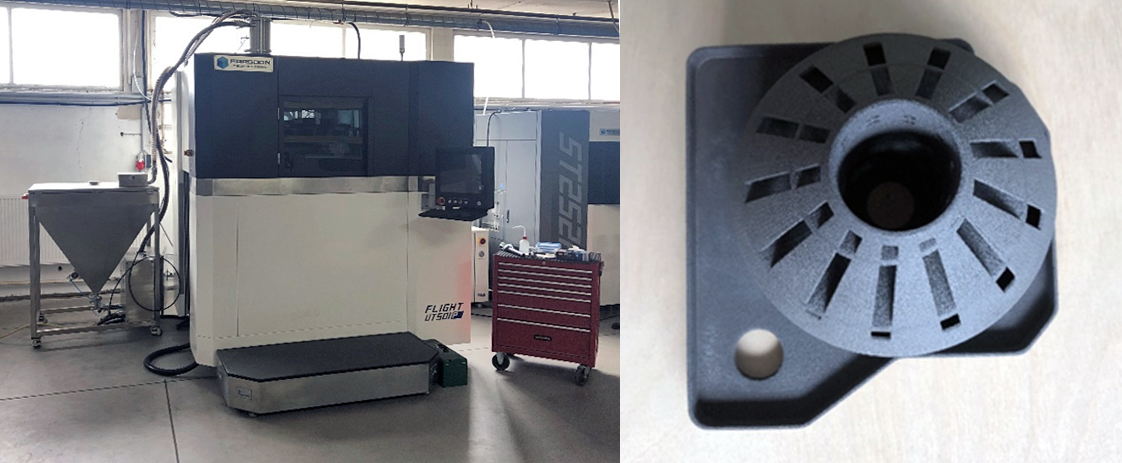

Figure 1 (left): FLIGHT UT501P at AM-Rauch production site

Figure 2 (right): Filter Housing made of LUVOSINT PPS 9268 BK. Image courtesy: Racing team of University of Stuttgart / Germany

After extensive testing aimed at qualifying high-performance polymers for new applications, numerous specialized high-temperature polymers are now successfully processed on FARSOON systems for volume production projects. This includes the development of process parameters for two distinct Polyphenylene sulfide (PPS) materials: TORAY PPS-GF25 and LUVOSINT PPS 9268 BK.

In recognition of this collaboration, AM-Rauch and Farsoon jointly worked on a customized large-format polymer PBF system Flight UT501P featuring robust fiber laser and ultra-temperature capability up to 340°C. Thanks to the expanded build volume of UT501P – for the first time, large-format parts with volumes up to 440 x 440 x 450 mm can now be produced targeting exceptional quality at highly competitive cost per part. Further materials from the PAEK family are expected to be qualified in the near future, expanding the range of high-performance polymers available for additive manufacturing.

Bernd Rauch, owner of AM-Rauch, oversaw the pilot phase and expressed great satisfaction with the collaboration between AM-Rauch and FARSOON Europe. “Apart from a few suggestions for machine improvements, we are very pleased with the system’s performance, which made the decision to fully integrate the machine after the pilot phase an easy one. We are excited for the next generation of UT large-format machines, which will be developed in alignment with customers’ requirements.”

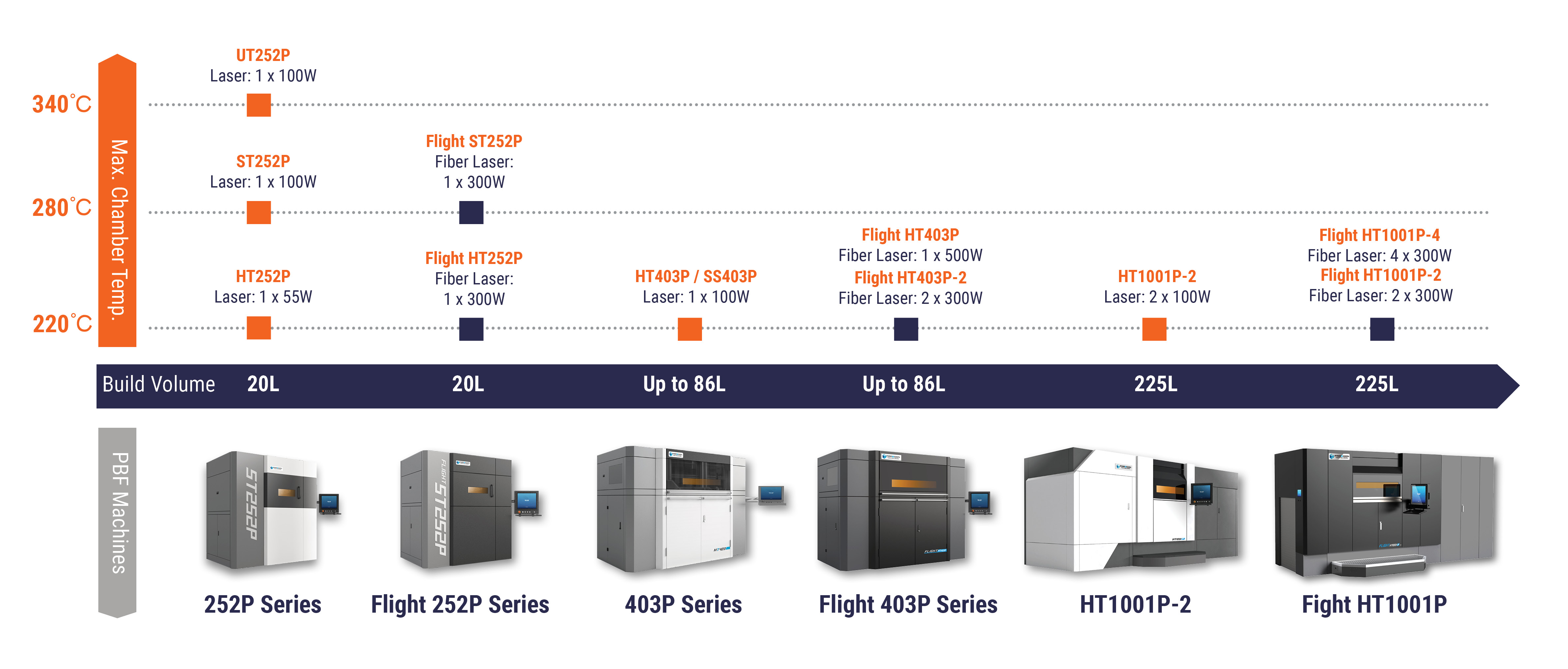

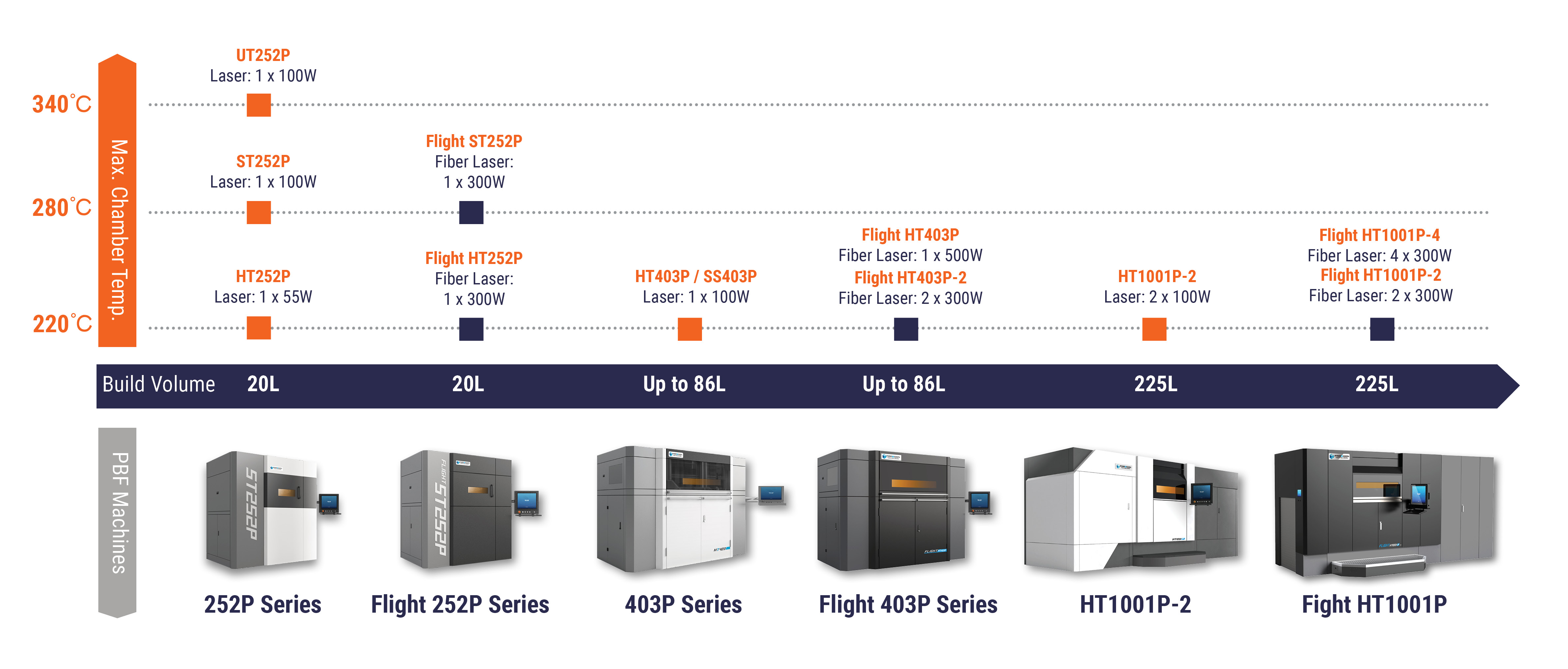

Farsoon has been at the forefront of high-temperature laser powder bed fusion (PBF) technology since 2014, with several high-performance PBF systems successfully introduced to the market capable of reaching chamber temperatures up to 280°C including ST252P. In 2023, Farsoon introduced the powerful UT252P platform with advanced chamber capable of processing materials like PAEK family with melting points exceeding 340°C making it ideal for high-temperature applications in material engineering, medical devices, aerospace, and beyond.

With strong commitment to advancing technology innovation with global industry partners and customers, Farsoon is dedicated to build a more connected and capable ecosystem that drives additive manufacturing into real-world application. Customers interested in Farsoon’s Ultra-temperature solutions are welcome to contact globalinfo@farsoon.com.

Figure 3: Farsoon High-temperature plastic PBF system in a glance

About AM-Rauch GmbH&CoKG

AM-Rauch GmbH&CoKG, based in Baden-Baden / Germany, is world-wide the only specialized service bureau for high-performance polymers in PBF technology. AM-Rauch began processing the high-performance polymer PEEK HP3 using the PBF in 2013. In addition to PEEK and PEKK materials, many special high-performance polymers such as PPS or PK are now processed on FARSOON systems. AM-Rauch is able to react quickly and easily to customer requirements thanks to its own expertise in process parameter development.

About Farsoon Europe GmbH

FARSOON Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Learning from the market about customer needs, Farsoon has moved to address the need for higher levels of productivity, improved feature details, and enhanced operational efficiency and flexibility. Farsoon’s latest innovations like the Continuous Additive Manufacturing Solutions (CAMS) and the very accurate and ultra-fast Flight™ Technology stand for highest production rates and real industrial use of Additive Manufacturing.

Farsoon´s subsidiary FARSOON Europe GmbH (Stuttgart, Germany) provides the whole range of machine portfolio after technical confirmation in China, as well as local service and maintenance activities.

Press Contact:

Mr. Yukio Tee

Tel.: +49 15154929344

E-Mail: yukio.tee@farsoon-eu.com