> New 3D printing PA6 material solution improve properties of components and saves costs

> BASF and Farsoon combine their strengths to make 3D printing mass production possible

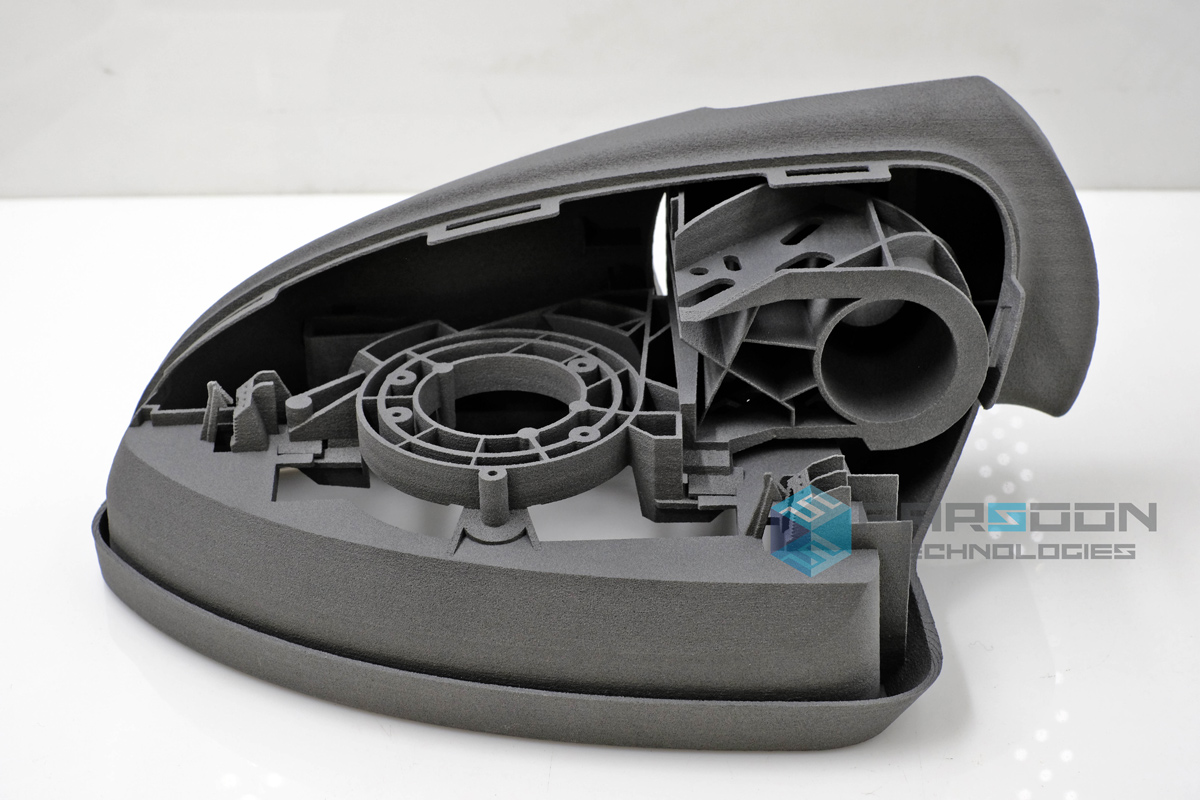

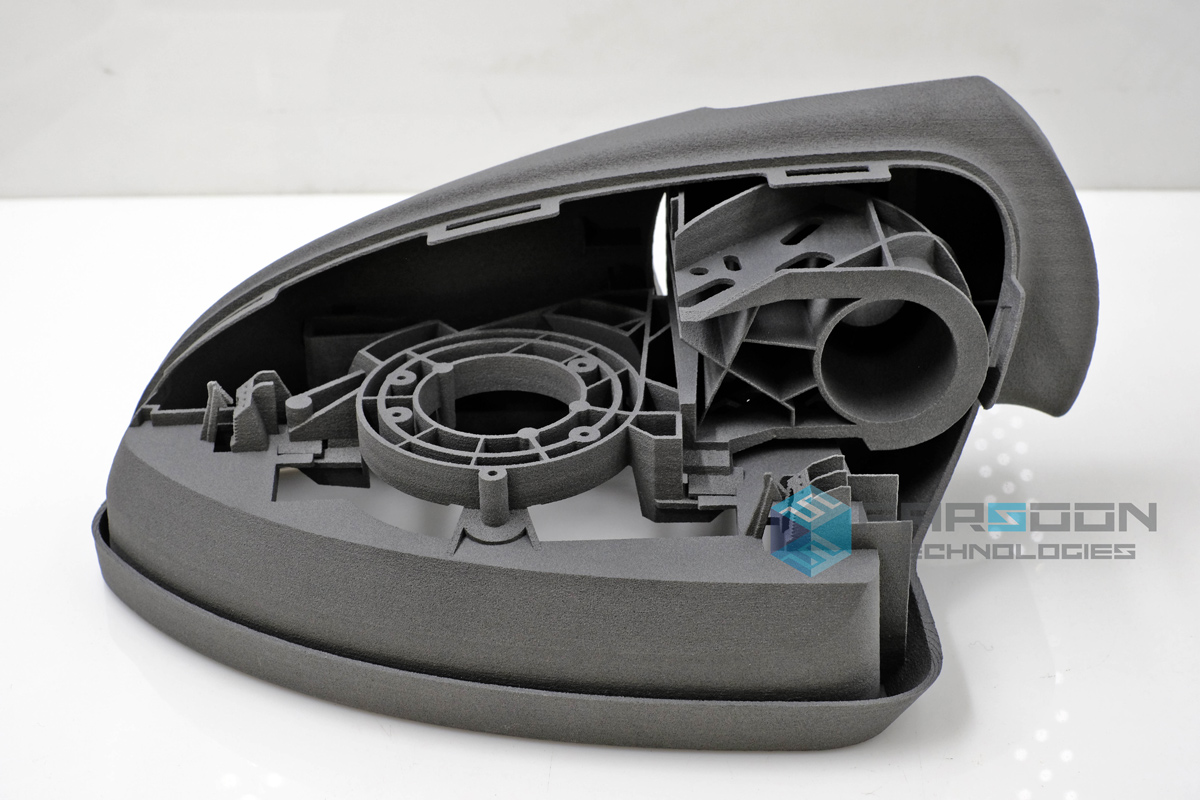

Rear-view mirror housing made from BASF Ultrasint PA6 X043 with Farsoon HT403P

Shanghai, China – February 28, 2018 – BASF, the world’s leading chemical company, and Farsoon, a leading Industrial 3D printing solution provider, have signed a strategic agreement to offer customers a new polyamide (PA) based 3D printing material solution in China. With the launch of BASF Ultrasint PA6 X043 Black, manufacturers can produce components with optimized shapes, reduced weight, and with the ability to withstand tough environments. This high-performance material will create new possibilities for a variety of industries, including aerospace, automotive and consumer.

Ultrasint PA6 X043 Black offers high strength, good recyclability and a high heat distortion temperature, at a competitive cost. Combined with Farsoon’s new continuous additive manufacturing solutions (CAMS) – HT1001P, HT252P, ST252P, HT403P – this material can help customers develop high performance components and significantly increase productivity.

“This new breakthrough in 3D printing materials makes direct manufacturing possible, which further accelerates the industrialization of 3D printing in China. In the future, Farsoon will continue to work closely with BASF to help customers enhance their equipment and material performance, while reducing production costs. We aim to offer customers a true additive manufacturing solution,” said Dr. Xu Xiao Shu, Founder and Chairman of Farsoon.

“BASF is dedicated to developing high performance 3D printing materials like the Ultrasint PA6 series. We provide an open platform by working with our partners, such as Farsoon, to develop competitive 3D printing material solutions to realize future customer needs for mass production,” said Mr. Michael Tang, Senior Business Development Manager of BASF 3D-Printing Asia Pacific.

BASF’s Ultrasint PA6 X043 Black material, along with the world’s largest polymer powder bed system, made with the Farsoon’s Continuous Additive Manufacturing Solution (CAMS) technology, will be presented at TCT Asia 2018.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. The more than 115,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into five segments: Chemicals, Performance Products, Functional Materials & Solutions, Agricultural Solutions and Oil & Gas. BASF generated sales of €64.5 billion in 2017. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (BAS). Further information at www.basf.com.

About Farsoon

Farsoon Technologies is a total solution supplier of industrial grade plastic laser sintering and metal laser melting systems founded in 2009 by Dr. Xu Xiaoshu. Farsoon has developed a team of world-class experts with competencies in tailored for developing additive equipment. Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the users the freedom to innovate and expand the envelope of additive technology for the world. It is our core belief that only by having an open system and finding new, better, and more cost-effective materials can the industry continue its rapid growth. Learn more about Farsoon at www.farsoon.com.