November 03, 2021, Stuttgart and Leverkusen, Germany

> Successful use of Covestro PBT and TPU powders on Farsoon plastics laser sintering machines

> Industrial 3D-Printing with high reliability and increased productivity

> Collaboration on new engineering-grade powder materials for end-use parts

Materials manufacturer Covestro operates Farsoon Laser Sintering Systems in their German and Dutch (legacy-DSM) additive manufacturing facilities for testing the processing and printing of new materials such as TPU, PP and PBT. Downstream customers have validated such parts for end-use applications in automotive, electrical and consumer industries. Based on customer feedback and success, the two companies are strengthening their collaboration to foster series production of 3D-Printing.

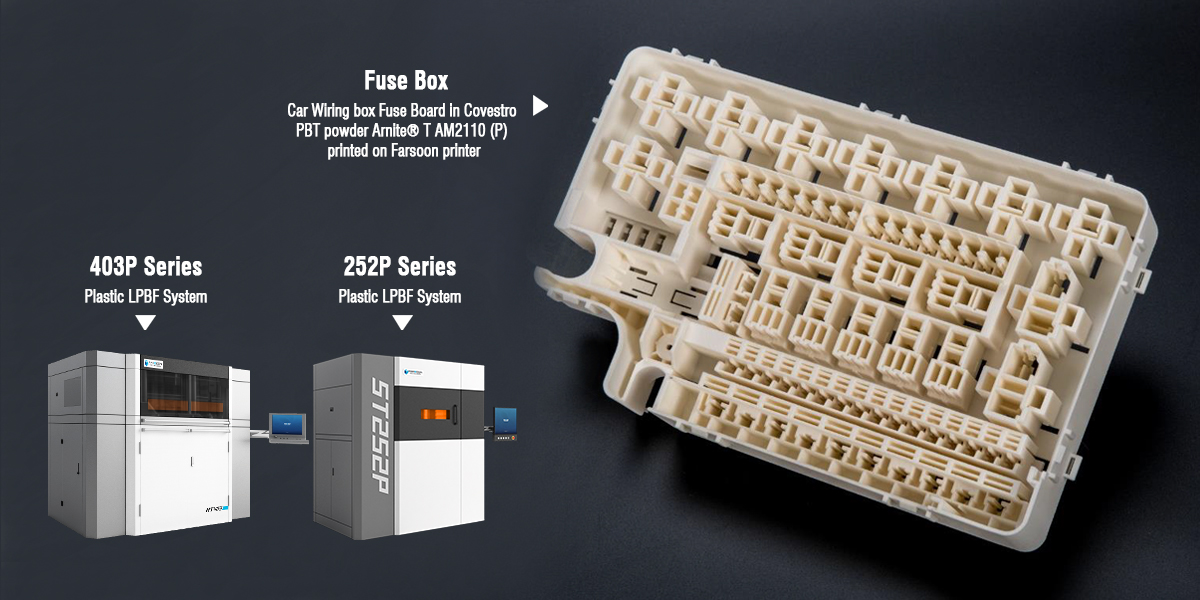

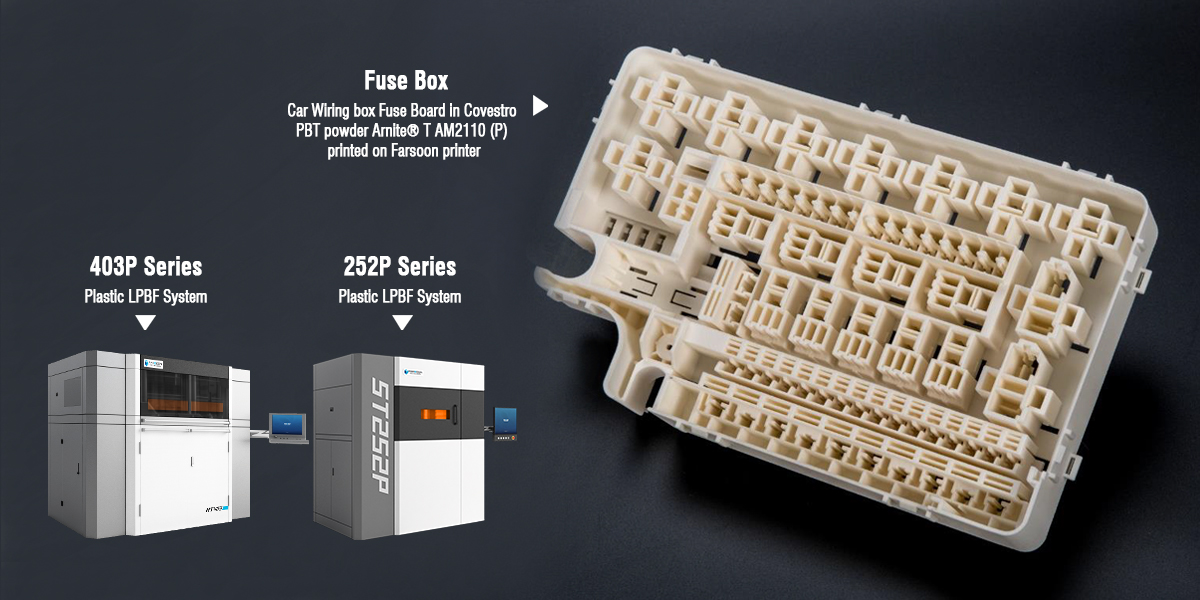

Both Farsoon and Covestro are committed to an open systems philosophy so customers are free to choose materials for their 3D-printing systems that suit their end-use applications. In this collaboration, Covestro is contributing its expertise in polymer-based 3D printing materials and Farsoon its expertise from powder-based laser sintering machines. Covestro has already successfully launched TPU and PBT polymer powders developed on Farsoon 252P-series machines. The development of additional powders and the upscaling to larger series applications is part of the strengthened collaboration.

Customer success

Covestro, Farsoon and Seifert Logistics Group (SLG) in Ulm, Germany, jointly developed TPU parts for footwear. Seifert Logistics fabricates TPU parts on a Farsoon SS403P at high productivity levels.

Covestro, Farsoon and a partner from the automotive industry collaborated to develop end-use parts for interior car applications using legacy-DSM PBT powder Arnite® T AM1210 (P).

“We are very pleased to extend the opportunities to the additive manufacturing market by proactively supporting new applications with new polymer powders,” says Dr. Dirk Simon, Managing Director of Farsoon Europe GmbH and member of Farsoon’s Global Management Team. “Farsoon SLS machines are very compatible with Covestro’s polymer powders, which offer a very interesting property profile to form an important foundation for our customers’ market success.”

Farsoon machines are all truly open systems which means operators can optimize process parameters for highest productivity at required part qualities for the material of choice. The High-Temperature (HT) and Super-Temperature (ST) configuration of Farsoon machines allow process chamber temperatures of up to 220°C or 280°C respectively. The machines are equipped with high-speed scanners and powerful lasers. Farsoon is committed to help making fabrication of 3D-parts cheaper, for instance with its Fiber-laser Flight™ Technology. The high productivity of parts’ production makes series applications increasingly accessible.

“By collaborating closely with printer manufacturers, we can test materials in the development process and provide customers verified material and printer solutions”, said Geoff Gardner, Innovation Director Additive Manufacturing at Covestro. “Farsoon SLS printers and especially their Flight™ Technology can run at standard and high temperatures so we can print PBT, PP and TPU all on the same printer. And with their higher accuracy and productivity, and lower cost per part, they are well suited for industrial production.”

Both companies will demo their polymer powder materials and printers at Formnext 2021, from 16-19 November in Frankfurt, Germany: Covestro at booth 12.1 C11 and Farsoon at booth 12.1 G19.

About FARSOON

FARSOON Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Learning from the market about customer needs, Farsoon has moved to address the need for higher levels of productivity, improved feature details, and enhanced operational efficiency and flexibility. Farsoon’s latest innovations like the Continuous Additive Manufacturing Solutions (CAMS) and the very accurate and ultra-fast Flight™ Technology stand for highest production rates and real industrial use of Additive Manufacturing.

Farsoon´s subsidiary FARSOON Europe GmbH (Stuttgart, Germany) provide the whole range of machine portfolio as well as local service and maintenance activities.

Press contact:

Mr. Nico Fiscella

Tel.: +49 711 13796 000

E-Mail: nico.fiscella@farsoon-eu.com

About Covestro

With 2020 sales of EUR 10.7 billion, Covestro is among the world’s leading polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative, sustainable solutions for products used in many areas of daily life. In doing so, Covestro is fully committed to the circular economy. The main industries served are the automotive and transportation industries, construction, furniture and wood processing, as well as electrical, electronics, and household appliances industries. Other sectors include sports and leisure, cosmetics, health and the chemical industry itself. At the end of 2020, Covestro has 33 production sites worldwide and employs approximately 16,500 people (calculated as full-time equivalents).

Learn more about legacy-DSM additive manufacturing on am.covestro.com and Covestro on www.covestro.com

Arnite® is a trademark of DSM.

Forward-looking statements

This news release may contain forward-looking statements based on current assumptions and forecasts made by Covestro AG. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. These factors include those discussed in Covestro’s public reports which are available at www.covestro.com. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.

Press contact:

Mr. Dr. Frank Rothbarth

Tel.: +49 214 6009-2536

E-Mail: frank.rothbarth@covestro.com