Changsha & Beijing, China, June 17th, 2020 – Farsoon Technologies and Siemens Ltd., China (referred to as Siemens China) announces the first milestone of industrial software integration, the first Farsoon system installed Siemens NX software now started beta-testing at customer site. After establishing the framework for integrated industrial solutions for additive manufacturing last September during the 21st China International Industry Fair (CIIF), Siemens and Farsoon R&D teams have been working intensively to push the technology integration. The goal of this collaboration is the implementation of Siemens’ end-to-end software and “Digital Twin” solutions on all Farsoon’s metal and plastic open platform industrial AM systems.

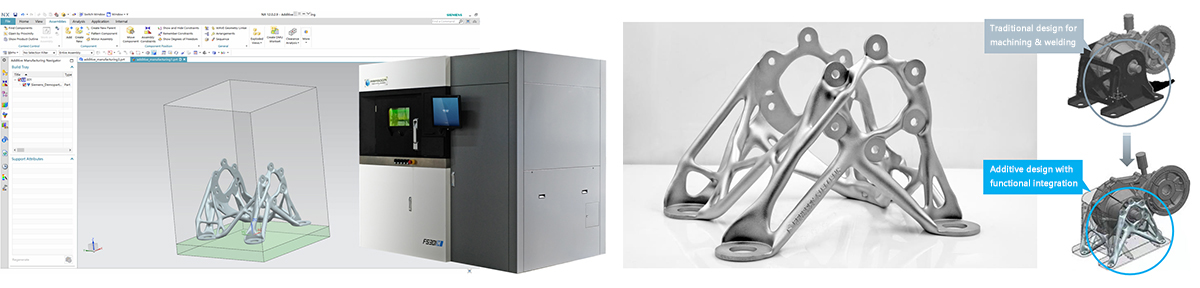

Figure 1: (Left) Farsoon and Siemens established additive manufacturing strategic collaboration at 21st CIIF. (Right) Siemens NX software in-house testing at Farsoon’s industrial additive manufacturing workshop, Changsha.

Integrating key functions including design, topology optimization, CAE verification, process simulation, build evaluation and scan-path planning, Siemens NX software has become the ultimate choice for leading industrial manufacturers. With clear focus on industrial additive manufacturing and “Open for industry” philosophy, Farsoon has established an increasing industrial customer base amongst aerospace, automotive, tooling, and large-scale manufacturing users. With joint experience and effort, Farsoon and Siemens will be able to offer customers with high-performance and streamlined “design-to-manufacture” industrial AM solutions.

In addition to software integration, General Manager of Farsoon Technologies-Hope Hou announced the first hardware integration at his presentation at Siemens booth during Formnext 2019: “The industrial control components from Siemens Digital Factory Solution have been applied to Farsoon’s latest metal laser sintering system FS301M, offering high-quality AM solutions to industrial users.”

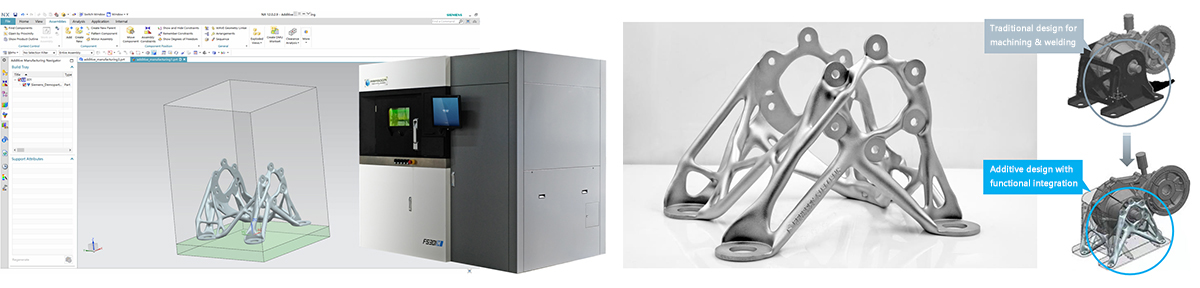

Figure 2: First collaboration part of Farsoon & Siemens: Aluminum Gearbox Mount from Siemens sponsored Formula Racing car. The part is designed by Siemens NX software and fabricated by Farsoon FS301M, size measuring 275 * 245 * 191mm, reduced weight of only 1.119 kg while maintain the same structural strength, simplified manufacturing process, and excellent surface finish: 3um (vertical), 5um (horizontal).

TCT Asia 2020 event:

Xia Weihua, Technical Director of Digital Industries Siemens Greater China, will deliver a presentation titled “NX Design-Simulation Platform and Case Studies“ at Farsoon booth E5-H07. Stay tuned with the detailed schedule to be announced!

About Farsoon:

Farsoon Technologies, founded in 2009 by Dr. Xu Xiaoshu, one of the true pioneers of laser sintering technology with more than 20 years’ experience in the industry, is a leading machine supplier of industrial Metal Laser Melting and Plastic Laser Sintering systems. Located in Changsha, Hunan Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. With clear vision of “Open for Industry”, Farsoon is committed to supporting industrial additive manufacturing with open systems, materials, parameters, and applications.

About Siemens:

Siemens AG is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. The company is active around the globe, focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries.