June 25th, 2024 – Rapid + TCT event, Los Angeles – In the traditional engineering polymers market, PA6 are widely used nylon materials accounting for over 80% of the entire nylon PA (polyamide) market. Compared to standard PA12 materials, PA6 offers higher mechanical properties, better heat resistance, and more competitive pricing, making it one of the top material options for mechanical and thermal stress-resistant components in automotive, electrical, and mechanical engineering.

Observing the increasing need for PA6 family materials in the industrial AM market, Farsoon Technologies has launched a high-performance carbon-fiber reinforced PA6 material FS6130CF-F, targeting high-demanding industries such as automotive, aerospace, electronics, and electrical devices. The high-performance FS6130CF-F is the perfect option for various industrial applications requiring heat resistance, strength, rigidity, modulus, and impact performance.

Figure 1: FS6130CF-F printed part performance compared to other technologies. Image courtesy: Farsoon

Amongst its well-balanced mechanical property profile, tensile strength is a true highlight thanks to the carbon-fiber orientation – it delivers an optimal performance in X direction exceeding 110MPa, 80MPa+ in Y direction, and 60MPa+ in Z direction of the mechanical properties of the printed components, makes it one of the strongest and most stiff materials compared to parts produced by other technologies.

The 3D printed parts with FS6130CF-F showcase good performances at high temperatures comparable to injection-molded PA6 fiber-reinforced materials; It offers a heat distortion temperature (HDT-1.8MPa) of 210°C, good dimensional accuracy without deformation or rupture during the stability test, suited for end-use applications in harsh environments.

Thanks to the advanced composition, the FS6130CF-F offers a low refreshment ratio — the proportion of virgin powder added during the printing process can be as low as 20% (virgin powder: residual powder ratio 2:8), significantly reducing material waste and cost – bringing a truly sustainable manufacturing process to series production customers. During the recyclability test, the material features ease of processing; enabling stable production of high-quality, repeatable parts.

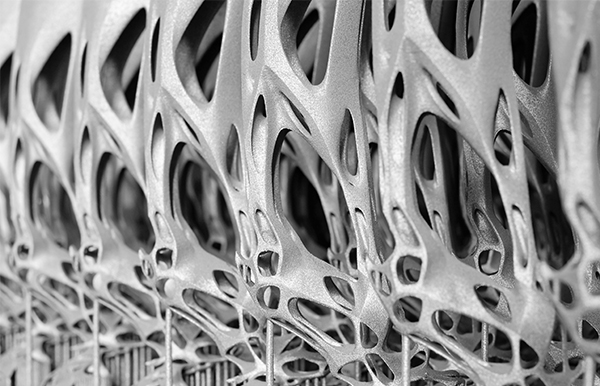

Figure 2: FS6130CF-F example applications. Image courtesy: Farsoon

The optimal performance of FS6130CF-F opens up many possibilities in end-use applications requiring load-bearing and lightweight. Take the NEV (New Energy Vehicles) for example, the carbon-fiber-reinforced FS6130CF-F can be used for customized metal replacement parts; it offers the required tensile strength while reducing the weight of the structure, which helps to achieve improvements of NEV in speed, performance, and lower energy consumption.

Developed for Farsoon’s “Flight” fiber laser PBF technology, the FS6130CF-F material is fully compatible with Flight HT403P-2 (dual-laser) and Flight HT/ST252P High-temperature laser PBF platforms. Thanks to the significantly higher laser power and scanning speed of the fiber laser compared to the traditional CO2 laser, the FS6130CF-F machine-material solutions are ready to deliver high-efficiency additive manufacturing solutions targeting industrial-scale batch production. Like all Farsoon systems, the Flight machine’s are open platforms, offering users the great benefits of running PA6 with validated parameters or exploring customized material processing as needed.

As a technology innovator, Farsoon has consistently pushed the boundaries in production scalability and material diversity in plastic laser powder bed fusion technology. The FS6130CF-F material is now available in the US and European markets for commercial orders. Inquiry or customers interested are welcome to visit Farsoon Technologies Americas at booth 2600 during the Rapid+TCT 2024 this week, or contact us: globalinfo@farsoon.com for more details.

About Farsoon Americas

OPEN FOR INDUSTRY – Farsoon Technologies is a global manufacturer and supplier of industrial-level polymer and metal laser sintering systems. Farsoon Americas was founded in the vibrant Austin, Texas area, to better service the North American market. Here at Farsoon Americas, we have built a local team of Additive Manufacturing experts focused on application support, service, and sales; with a focus on customer-centric development and technical support infrastructure.

https://www.farsoon-gl.com/