November 13-16, 2018 – Formnext @ Frankfurt am Main – the biggest and most important industrial additive manufacturing show in Europe and the world, Farsoon Technologies, for the first time with own booth, welcomed industrial visitors to a great adventure.

The brand-new booth design is with its open layout and warm “dawn light” coloring reinforce Farsoon’s – “Open for Industry” philosophy. Open for Industry as Farsoon understands it will bring significant benefits for our customers: Open Material strategy means that the customer will have the freedom of choosing high quality Farsoon materials or third-party materials. Open Configuration means that customers have access to machine parameters giving customers the flexibility and power to control their builds. Open Application means that the ability to customize materials and parameters allow a wider range of applications. Finally, Open for Partnerships means that Farsoon recognizes the needs of close partnerships in areas such as material, automation, software, and many others, which enables additive manufacturing for true industrial scale production.

“Open for Industry” booth design from Farsoon at Formnext

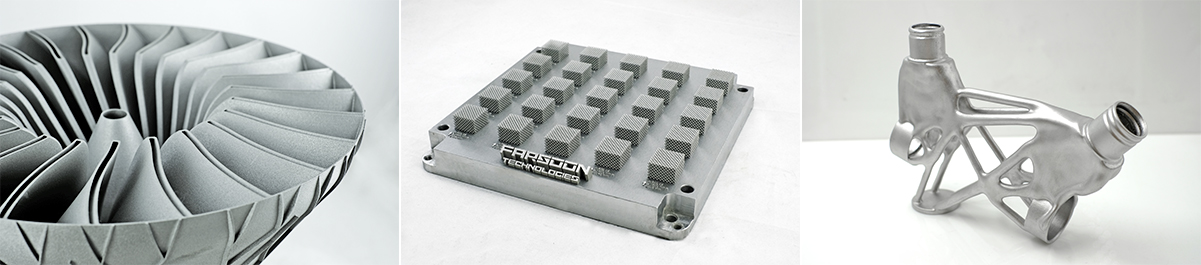

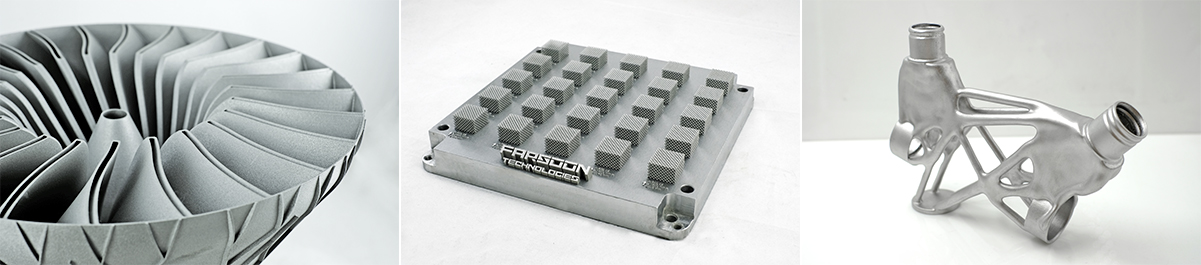

The results of these key approaches of “Openness” are shown by the 3 columns in the booth: Column 1 “Open Parameters for Productivity & Cost Reduction” shows comparisons of productivity, cost and performance achieved by having control of machine parameters. Column 2 “Control of Part Properties for Your Industry” showcased a wide range of industrial applications produced with best optimized parameters and materials according to functional requirements and mechanical properties which can be achieved. Column 3 “High Productivity for Metal through Open Parameters” presented a series of metal lattice structures achieved by differently tuned parameters in a single build and a Titanium Turbine Cooling Testbed, which is printed by Farsoon large-format metal laser melting system FS421M, with the part size of 365 * 365 * 320 mm.

Display of plastic applications in column 2

Display of metal applications in column 3

After establishing FARSOON Europe GmbH in April earlier this year, Farsoon has been continuously investing in building up its regional service and maintenance capabilities to ensure high quality and on time support for European customers.

Farsoon is committed to pushing the boundaries of additive manufacturing production by “Open for industry” approach – offering user full freedom of innovation and expanding the envelope of what laser sintering technology can achieve. On November 14th Dr. Dirk Simon – Managing Director of Farsoon Europe delivered the presentation titled “Farsoon now in Europe: committed to series AM” at TCT’s Introductory Stage, wherein he reinforced Farsoon’s commitment in Europe and its core belief of open for industry for the additive manufacturing market. On November 14th during a Press Conference held at Farsoon’s booth, Dr. Xu Xiaoshu, Founder and CEO of Farsoon, together with Dr. Simon, formally introduced Farsoon to the Europe’s AM industry media where Farsoon’s commitment to Industrialization received many compliments and interactions.

Dr. Xu Xiaoshu, Founder and CEO of Farsoon and Dr. Dirk Simon, Managing Director of Farsoon Europe speak to AM media representatives at Farsoon’s booth

During the Formnext show, Farsoon for the first time in Europe, showcased its latest AM innovation that “surprising the additive industry”– HT1001P – A Continuous Additive Manufacturing Solution (CAMS) system, and meanwhile further announced the launch of Beta testing programs with two Industrial AM customers in Europe and North America.

Farsoon’s HT1001P system enables the fabrication of large parts (build envelope of 1000 x 500 x 450 mm) with engineering plastics, such as reinforced PA6. With its unparalleled productivity, large build envelope and continuous operation feature, Farsoon has become a trendsetter for increasing competitiveness of additive manufacturing and provides a thought-through solution for industrial level production of functional parts at a substantially lower cost. Showing 3 full modules including a pre-heating/loading station, building station and cooling station all connected by an internal conveyor system, the HT1001P received strong attention and inquiries from many Industry users.

Left: The HT1001P in operation; Right: The HT1001P was well received at Formnext

The exceptional productivity of HT1001P was showcased by two large parts displayed at the booth. Symbolizing the high reaching goals of Farsoon and its partners the Flying Tiger P40 model was successfully produced on HT1001P and hung over the machine along with the slogan “Large – Robust – Accurate”. The HVAC Unit, measuring 810 * 465 * 431 mm – was printed as a single piece in 18 hours with Farsoon’s FS3300PA material showing the high productivity of the HT1001P system.

Flying tiger P40 Model and HVAC Unit (produced in one-piece) measuring 810 * 465 * 431 mm, fabricated on HT1001P

With its innovative technologies and international strategy, Farsoon has established a solid industrial customer base in Asia – Pacific region. While still new to North American and European markets, Farsoon is actively engaged in working with AM customers in these regions. By providing new technologies, reliable support and open mindedness towards working with customers and partners for best solutions, Farsoon hopes to accelerate the growth of the AM industry towards true industrialization.

About Farsoon Technologies

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009 in China, is a global comprehensive solution supplier of industrial grade polymer laser sintering and metal laser sintering systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.