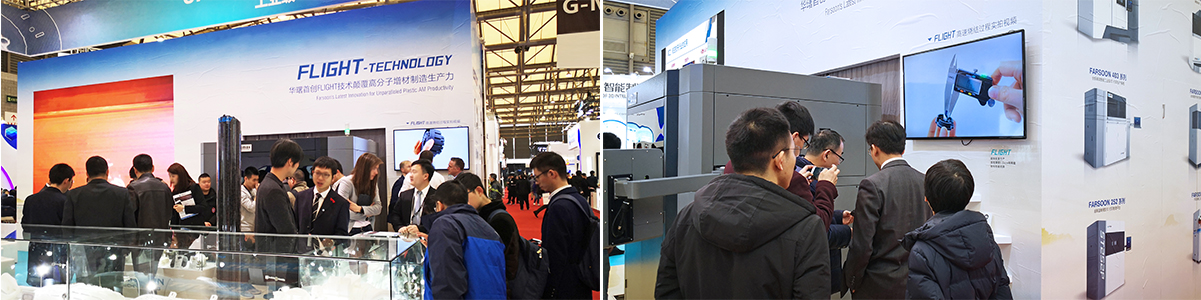

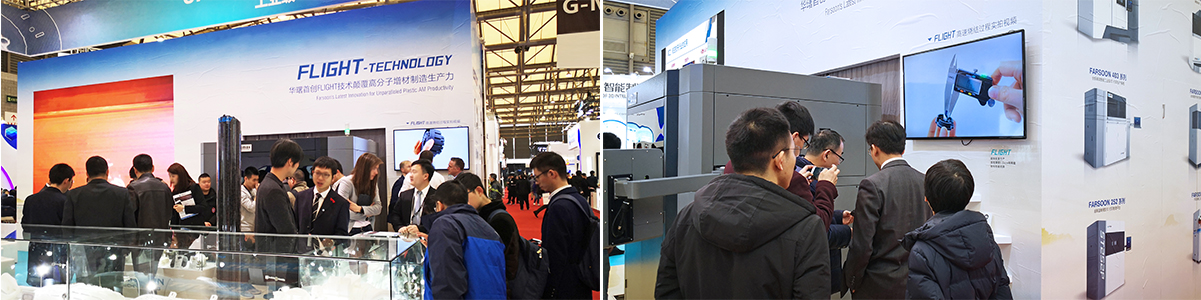

Feb. 21-23, 2019, Shanghai, China — TCT Asia — one of the biggest industrial additive manufacturing shows in the Asia-Pacific area, Farsoon Technologies once again showcased to visitors its ability to develop industry leading innovation.

(Fig 1, top left) Farsoon booth at 2019 TCT Asia

(Fig 2, top right) Dr. Xu Xiaoshu, Founder and Chairman of Farsoon, first presented Flight™ Technology at the TCT Introducing Stage

Dr. Xu Xiaoshu, Founder and CEO of Farsoon, announced the development of its new Flight™ Technology at the TCT Introducing Stage. Addressing the market need for higher levels of productivity, improved feature details, and enhanced operational efficiency. Farsoon has combined powerful fiber laser technology with plastic laser sintering systems, the new technology will greatly enhance the productivity of the current state-of-the-art laser sintering systems. At the Farsoon booth, a 403P system was showcased with the new Flight™ Technology amazing visitors with it’s speed of production and fine part details. The operational machine attracted continuous attentions and inquiries from trade show guests and industry experts.

(Fig 3, top left) Flight™ Technology received continuous inquiries at the booth

(Fig 4, top right) Visitors were impressed by the high feature resolution on parts produced by Flight™ Technology

(Fig 5, top left) Farsoon showcased the productivity of Flight™ Technology compared to standard Plastic laser sintering

(Fig 6, top right) Daniel O’Connor and Samuel Davis from TCT Magazine interviewing Dr. Xu Xiaoshu, Founder and chairman of Farsoon, Dr. Dirk Simon, managing director of Farsoon Europe and Chenlu Fang, Farsoon global marketing manager at Farsoon booth

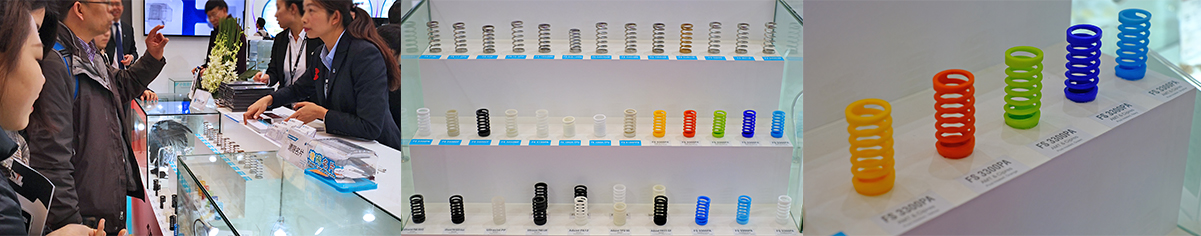

With the company philosophy “Open for Industry“, Farsoon showcased a wide range of AM solutions covering industries such as aerospace, automotive, medical, dental, and tooling amongst many others. Farsoon’s “Open system”, which includes open materials, open configurations and open applications, is able to help Farsoon customers greatly enhance their AM productivity and ROI.

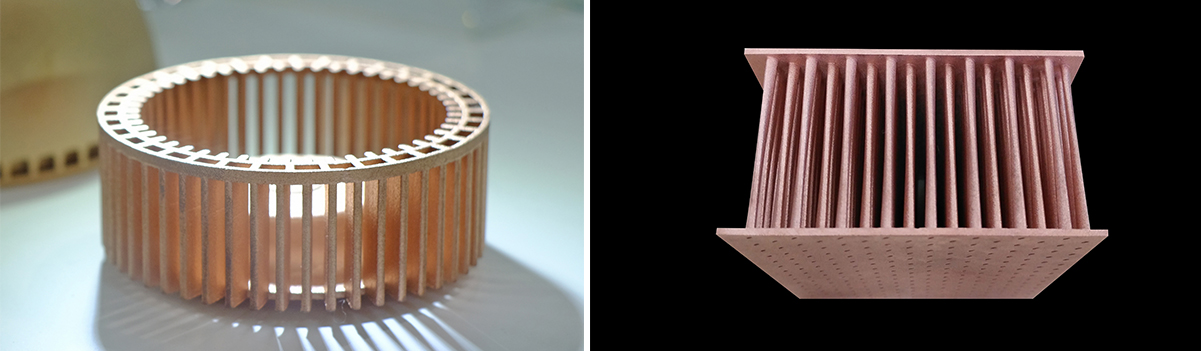

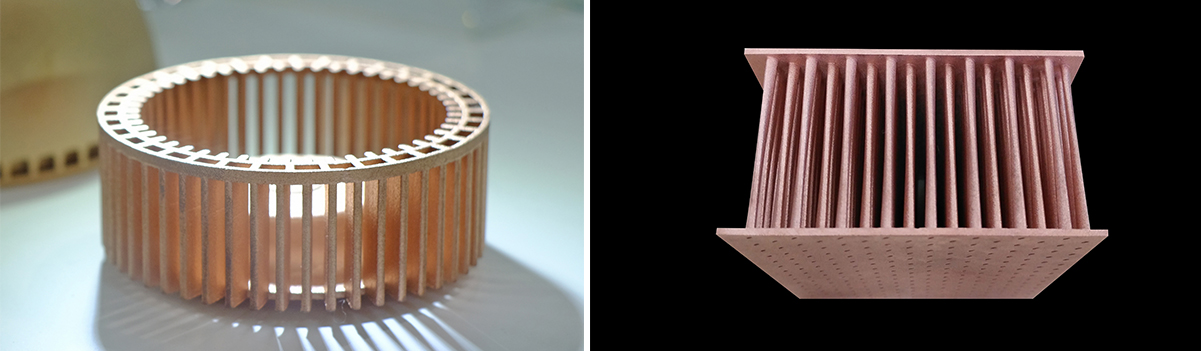

One featured part on display was the pure copper heat exchanger. Produced with a unique process developed for Farsoon systems, Farsoon engineers were able to help the customer produced part with good density and performance from this challenging material.

(Fig 7, top left) Display of pure copper heat sink

(Fig 8, top right) Display of pure copper heat exchanger with channel structure as thin as 0.5mm

(Fig 9, top left) Display of metal applications in Aerospace

(Fig 10, top right) Display of light-weight Tantalum implants with medical partner

(Fig 11, top left) Large HVAC unit build as one-piece on Farsoon CAMS HT1001P measures 810 * 465 * 431mm (31.89 * 18.3 * 16.97 in)

(Fig 12, top right) Large automotive front grill produced on Farsoon CAMS HT1001P

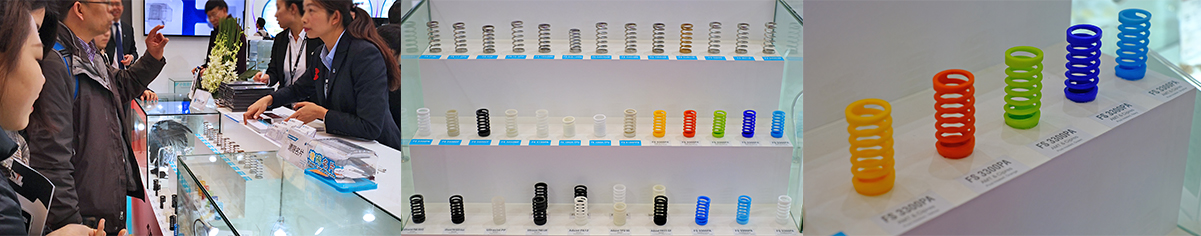

(Fig 13, top) Display of material springs: with unique open material strategy, Farsoon system is capable of processing a wide range of metal and plastic materials, and showcasing customer the options of post-processing by open partnership

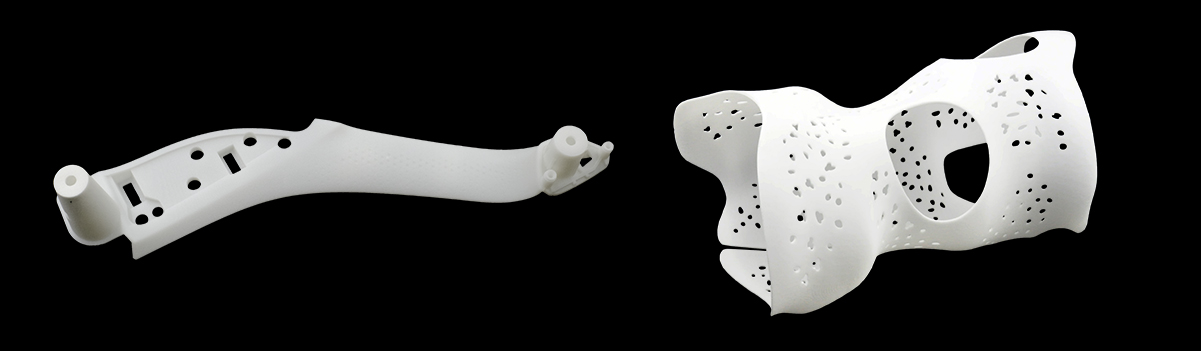

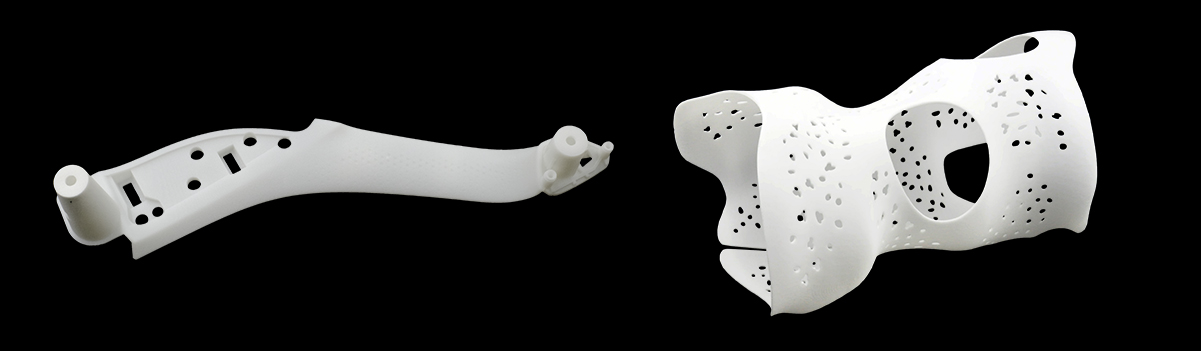

During the TCT show, Autodesk, Arkema and Farsoon also announced a three-party collaboration to accelerate industrial production for additive manufacturing. Working together, the three companies will strive to develop an open ecosystem by optimizing and integrating hardware, software, and material workflow.

(Fig 14, top) Display of plastic automotive arm-rest and rehabitation apparatus printed with Arkema PA11 material on Farsoon SS403P system

On the second day of TCT Asia, Farsoon held the Aerospace & Aviation AM Conference which attracted over 100 experts and keynote speakers from the Chinese and international aerospace industries including Honeywell, COMAC, Oerlikon, CASIC, ANSYS. The keynote speakers explored the general trend of aerospace & aviation AM technology along with application cases. Each speaker shared their innovative projects and success stories as well as collaboration efforts with Farsoon’s open systems. Along with the Aerospace & Aviation conference, Farsoon held several presentations at its booth during the three-day show. These presentations showcased Farsoon applications covering a range of topics from material, to software, to applications in the aerospace, automobile, and medical industries.

(Fig 15, top left) Farsoon Aerospace & Aviation AM Conference

(Fig 16, top right) Presentations of Farsoon application case studies at booth

Celebrating its 10th year anniversary in 2019, Farsoon is committed to developing AM technology towards industrial applications. With the core philosophy of “Open for Industry”, Farsoon is looking forward to working industry partners to build a better future for the additive ecosystem. Keep tuned to learn the latest innovations from Farsoon, we look forward to bringing more innovation and surprises to the AM industry!

About Farsoon Technologies

OPEN FOR INDUSTRY – Farsoon is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2017 Farsoon released the first of a new series of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS-Continuous Additive Manufacturing System) systems, and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe. Farsoon is committed to developing AM towards its true manufacturing potential and providing customers with best-in-class systems, materials, software, applications and services.