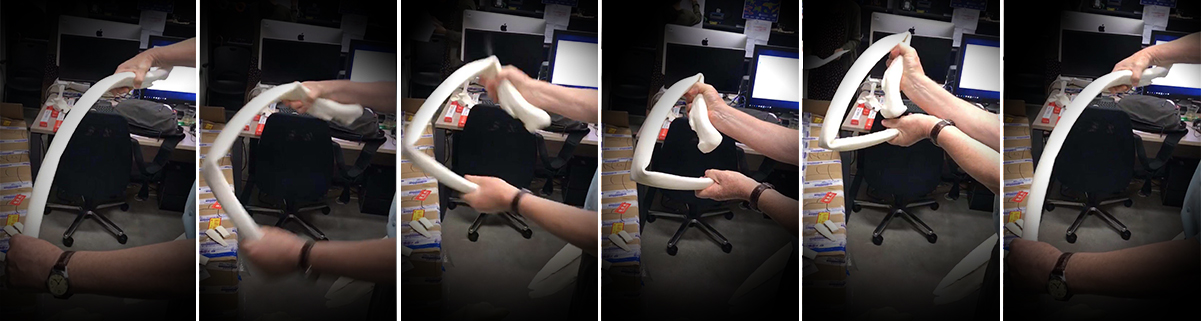

In 2014, the remains of a 10.8-meter-long “Omura” whale was found beached in Hung Shek Mun, Hong Kong. The “Omura” species of whale was first discovered in 2003 and the body was identified by genetic analysis. In order to retrieve the complete biological information, the whale skeleton was 3D scanned by staff from the Jockey Club College of Veterinary Medicine & Life Sciences as well as students from City University of Hong Kong.

Display of 3D printed “Omura” at City U Exhibition Gallery, Photo courtesy Xuberance

Recently at the City University of Hong Kong, an animal exhibition is set up to highlight the skeletal structure of a variety of animals fabricated by different technologies, which attracts hundreds of visitors each day. As a highlighted display of the exhibition, a mockup of the whale skeleton is on display. The skeleton can be assembled based on matching the numbers marked on each “Omura” whale bone along with instructions. A rare video of an “Omura” whale underwater also shows visitors the real size and movement of this animal.

The build of this skeletal mockup was based on the scan data from Jockey Club College of Veterinary Medicine & Life Sciences. Xuberance, a digital design company located in Shanghai, and CAMC, an additive manufacturing service bureau located in Chongqing, further collaborated to transform the scan data into a series of 3D digital models and to reproduce the full set of skeletons on Farsoon’s Plastic Laser Sintering system 402P series.

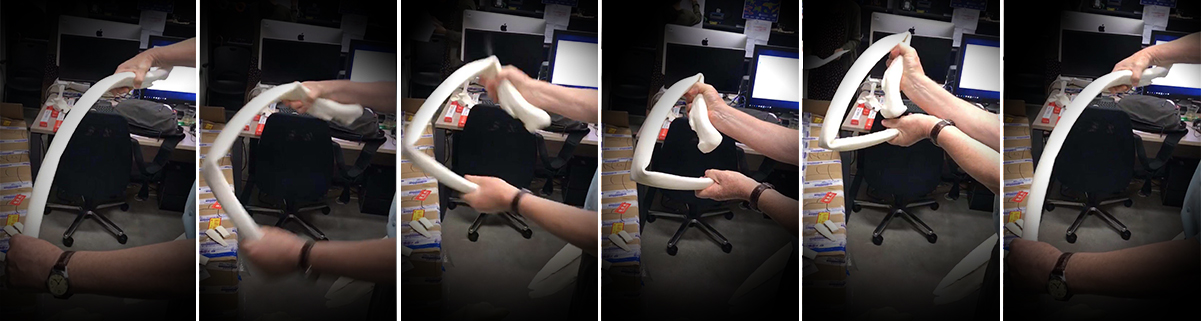

Intended to invite visitors to interact with the installation, the “Omura” is 3D printed using TPU (thermoplastic polyurethane) – an elastic material with good strength, flexibility and hand feel properties. Thanks to Farsoon’s “Open Parameter” capability, the 402P series is able to tune parameters to achieve best performance from the material. By working closely with Xuberance, engineers from CAMC were able to optimize the processing parameters to ensure the final parts achieve the designated impact and flexural strength while retaining ductility. ” We received a lot of positive feedback since the opening of the exhibition” said Luo Tao, CAMC General Manager, “The high strength ensures the durability of the installation while the material is soft and safe enough for children to play with.”

Bend Test Image

Exhibitor test – bend the finished parts at City U Exhibition Gallery, to ensure the 3D printed skeleton is able to bend or drop without any damage. Image courtesy Xuberance

3D printed “Omura” assembly, Photo courtesy Xuberance

About City University “Animal Show”

Organizer: City University of Hong Kong, National Palace Museum Taiwan

Concept: Jeffrey Shaw

3D Printing design: Xuberance

Production: CAMC, The Jockey Club College of Veterinary Medicine and Life Science, ACIMI School of Creative

About Xuberance

Xuberance is a world-renowned 3D printing design company dedicated to providing 3D design and research services worldwide, focusing on 3D data services, 3D product customization and 3D printing related research, development and user training. Founded in 2008 by Steven Ma, Xuberance is the first professional 3D printing design company in China, covering a wide range of fields including art, fashion, jewelry, interior, architecture, and industrial product design. For more information, please visit: http://www.xuberance.com/

About CAMC

Chongqing Additive Manufacturing Center (CAMC) is a service supplier of additive manufacturing production. It is located in Gangcheng Industrial Park in Jiangbei District, Chongqing. CAMC currently operates multiple Farsoon plastic and metal systems, including 402P Series, 252P series, FS271M and FS121M. For more information, please visit: http://www.camc3d.com