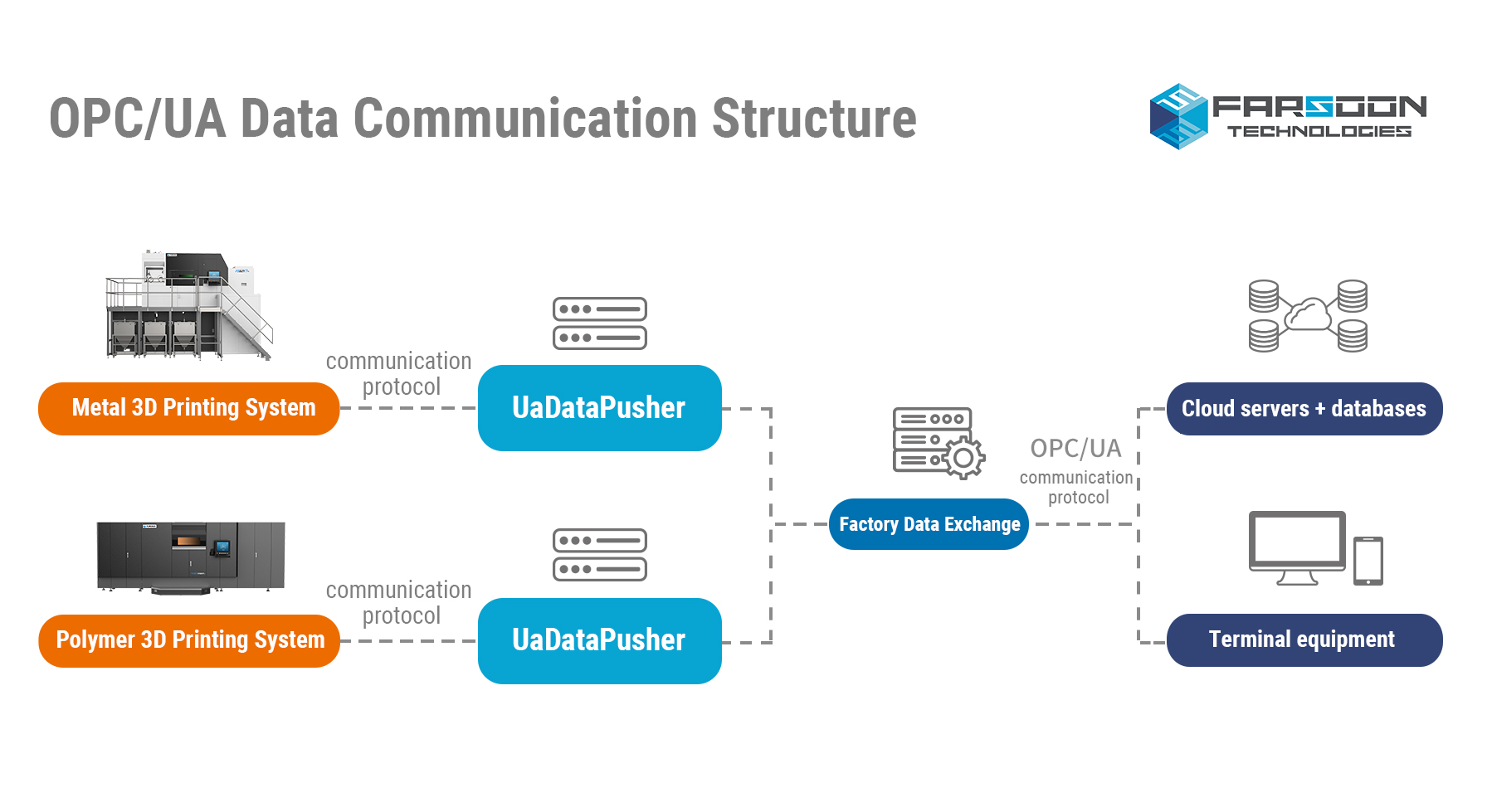

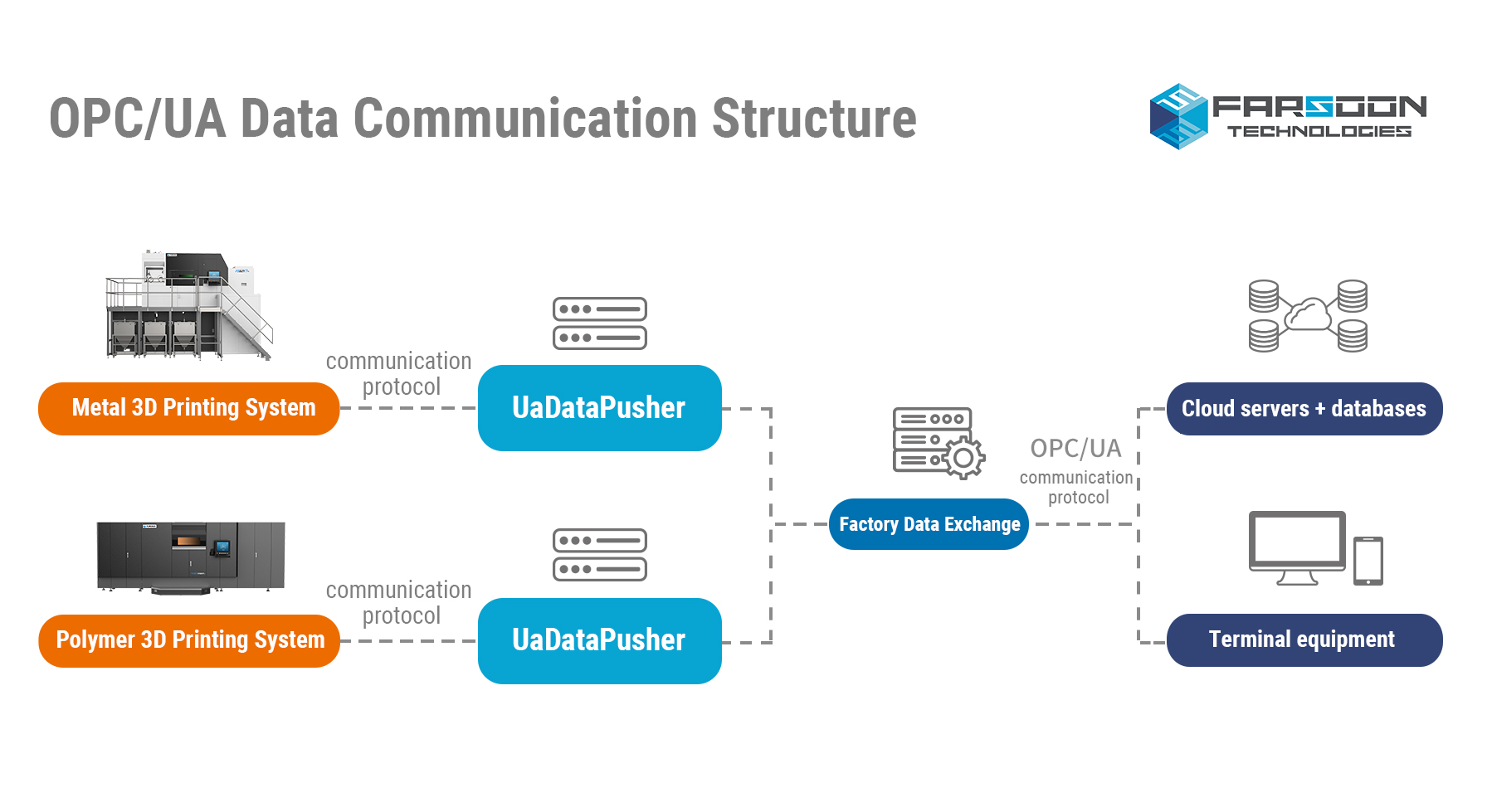

The OPC Unified Architecture (OPC/UA) communication protocol, developed by the OPC Foundation, is an advanced technology designed to enable seamless connection across an entire smart factory, from a single device to the enterprise-scale data flow. It features cross-platform compatibility, high security, and structured address space, making it a powerful tool for industrial automation.

Introducing UaDataPusher

Leveraging the OPC/UA communication protocol, Farsoon Technologies has officially launched UaDataPusher to the global market, an advanced communication software developed in-house. UaDataPusher helps businesses across industries and scales efficiently collect, analyze, and centralize vast amounts of serial production data from manufacturing environments. By facilitating seamless data exchange in 3D printing, it enables manufacturers to extract valuable insights, enhance production efficiency, and implement smart manufacturing solutions.

Real-Time Data Collection and Storage

Farsoon’s UaDataPusher integrates the OPC/UA communication protocol to support seamless client communication and data transmission. The software can be installed on Farsoon metal or polymer 3D printing system, enabling real-time monitoring of over 20 key operational parameters, including machine performance, build process parameters, and job package data. These insights are then shared via Farsoon’s MakeStar software to an OPC/UA server for further processing.

The key advantages of UaDataPusher include:

• Rapid data collection with centralized storage and analysis

• Seamless compatibility with both existing and future systems

• Simplified configuration and maintenance

• Expanded communication range and enhanced performance

Furthermore, authorized factory managers can access real-time machine data anytime, anywhere, ensuring secure and reliable communication between data acquisition and management systems.

Additionally, UaDataPusher integrates with Farsoon’s MES (Manufacturing Execution System) and other digital production management platforms to enable cross-platform data synchronization. This capability helps users streamline operations, reduce costs, and implement precise production orders.

UaDataPusher Implementation in Europe

A renowned research institution in Europe, specializing in polymer and metal material development as well as additive manufacturing processes, has been using Farsoon’s high-temperature polymer 3D printing system—252P Series—since 2018. In November 2023, they integrated UaDataPusher into their production environment, successfully achieving real-time monitoring and data analysis of their manufacturing activities.

As part of its daily operations, the research facility requires continuous monitoring and documentation of equipment status, production progress, and print quality. With UaDataPusher, they have achieved transparent, seamless data exchange across all production stages. The software enables regulated maintenance and process optimization, resulting in improved production efficiency, enhanced workflows, and reduced manufacturing costs. UaDataPusher provides comprehensive data-driven feedbacks to support production operations, equipment management, and factory oversight.

Farsoon remains committed to driving the rapid advancement of additive manufacturing technologies. By integrating data-driven automation solutions, Farsoon continues to push beyond traditional single-machine, discrete production models toward a fully connected, industrial ecosystem. If you are interested in high-volume additive manufacturing or OPC/UA communication solutions, feel free to contact us at: globalinfo@farsoon.com.