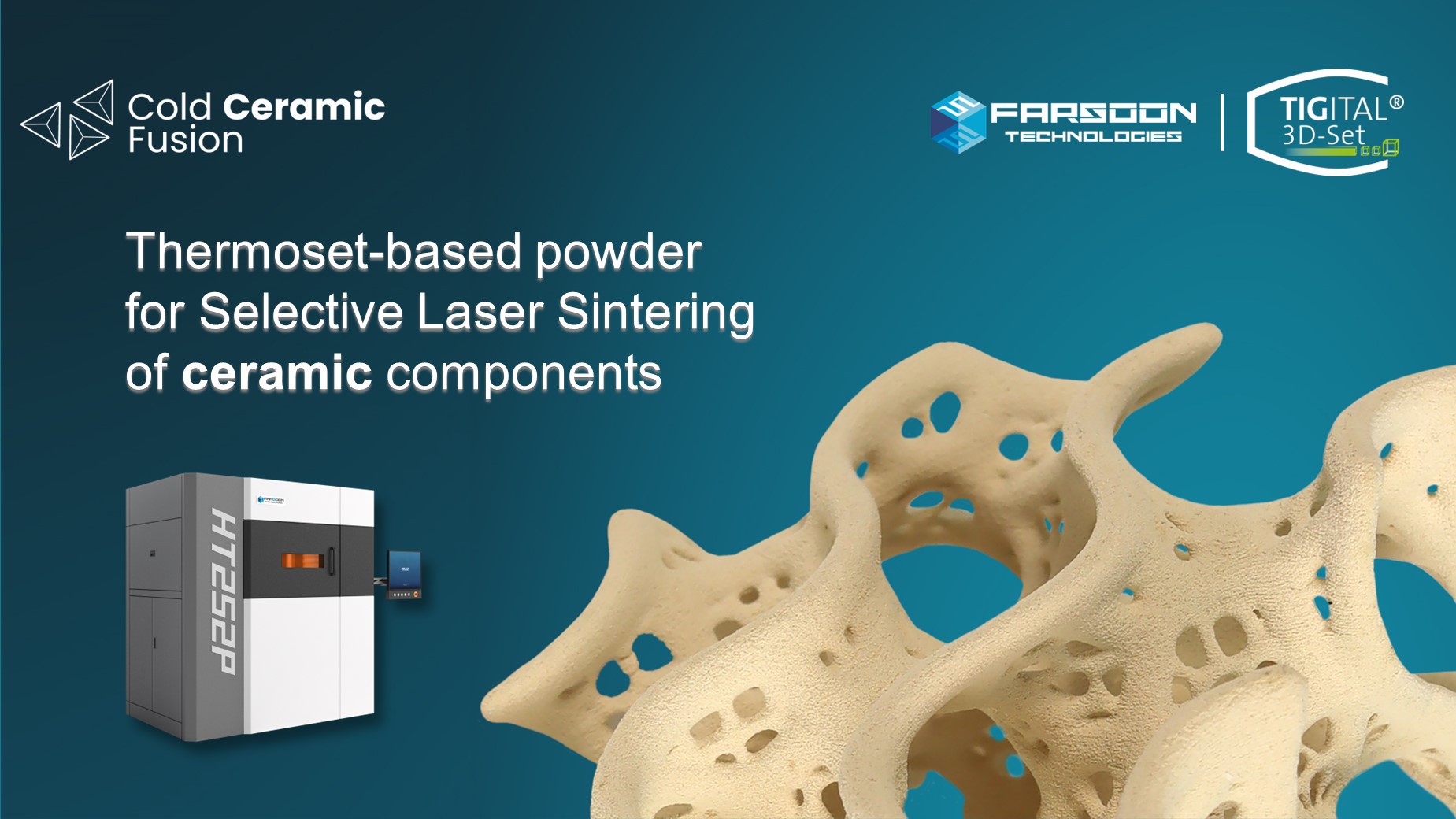

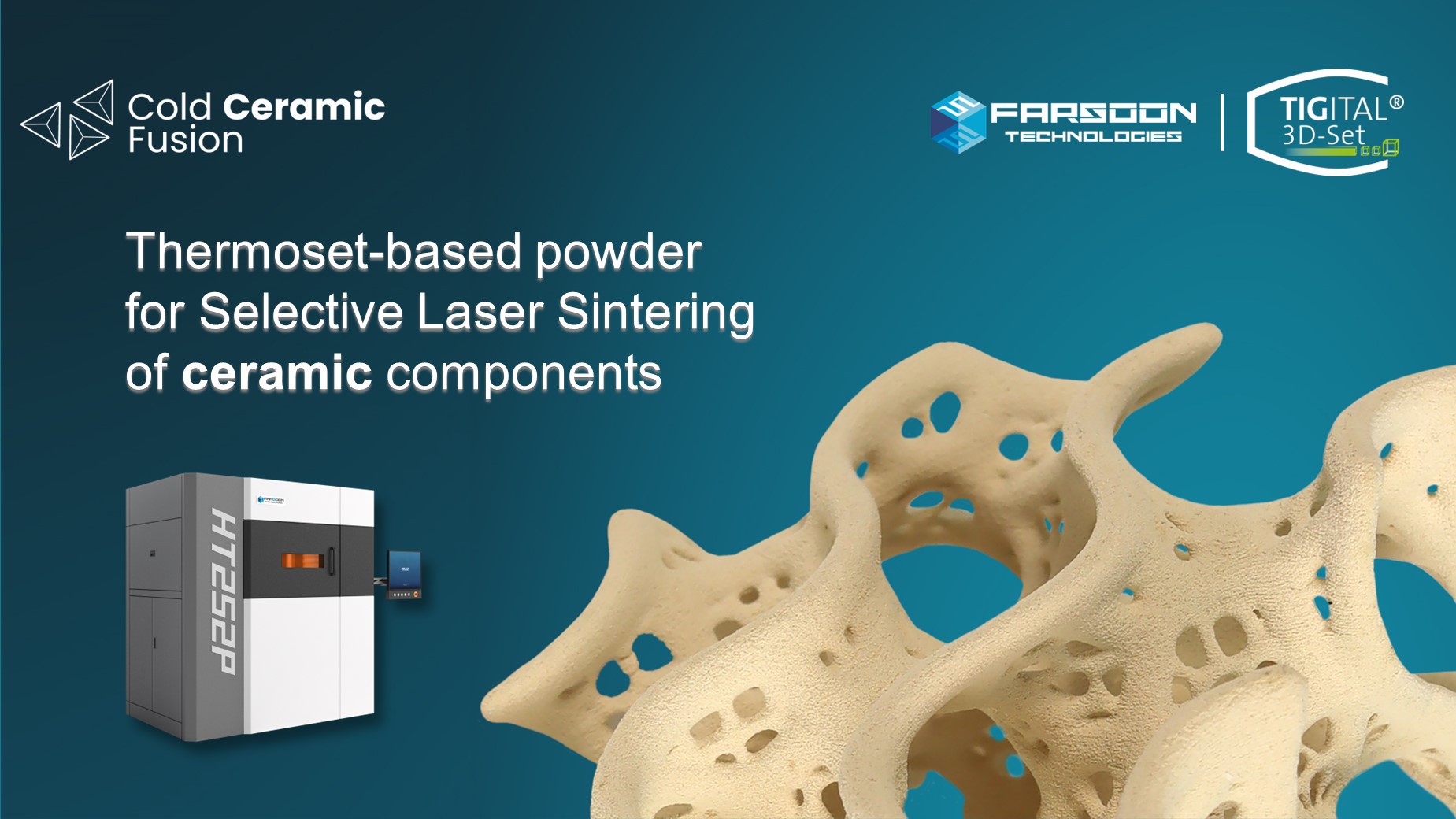

TIGER Coatings, manufacturer of TIGITAL® 3D-SET thermoset SLS (Selective Laser Sintering) materials and 3D Printer manufacturer Farsoon are collaborating on the release of a ceramic thermoset-based material for PBF (Powder Bed Fusion) based on Farsoon’s open SLS platform HT252P. TIGITAL® 3D-SET are expanding their material portfolio for the additive manufacturing industry to unlock new markets and provide new solutions for customers in the ceramic industry.

The Cold Ceramic Fusion process now offers the advantages of 3D SLS printing for the additive manufacturing ceramic industry. What clients can expect is superior productivity with a large build size and good resolution compared to other ceramic AM (Additive Manufacturing) technologies.

TIGITAL® 3D-Thermosets offer the best solution for incorporating and printing ceramic precursors, such as alumina and titanium dioxide. One of the biggest advantages is the uniform and highly predictable shrinkage in all dimensions compared to other printing technologies for ceramics.

The material is developed within CerAM SLS research project together with Fraunhofer IKTS and Hochschule Mittweida with the aim of producing a water treatment module for photocatalytic water cleaning.

TIGITAL® 3D-Thermosets are easy to print on open polymer SLS devices such as Farsoon’s HT252P at very low temperatures and provides major benefits for a wide variety of applications including the renewable energy and electronic component market as well as the chemical industry.

As an example, the porous structures that can be fabricated with TIGITAL® 3D-SET ceramic materials make them perfect for catalysis and filtration applications. Several beta-tested materials are available, and we are looking forward to meeting you at Formnext 2023 (TIGER Hall 11.0-C68 and Farsoon Hall 11.1-C11).

Oliver Li, Managing Director of Farsoon Europe GmbH states, “At Farsoon, we value the innovation and technology are key to business success as we keep driving the new materials and processes for industrial AM applications with our open-platform PBF 3D printing systems. We are thrilled to explore a brand-new application direction of producing ceramic parts on our laser PBF system with TIGER Coatings, in addition to our current metal and plastic PBF solutions. This not only adds one more innovative material option for the LPBF user of Farsoon but also offers a high-quality alternative for the CIM (Ceramic Injection Molding) user.”

Clemens Steiner, CEO of TIGER Coatings GmbH & Co KG states, “We are proud to further expand our portfolio from high performance polymers for fire retardant applications and drive our innovation strategy into ceramic PBF solutions. Using Farsoon’s open SLS devices gives us the possibilities we need, to explore and find new solutions for the AM industry to apply other material options easier and faster. With this brand-new ceramic material, we opened a superior alternative for users looking for the production of high-quality ceramic parts on PBF systems.”

About Farsoon:

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial-level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2017, Farsoon released the first of a new series of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS) and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe. Farsoon is committed to developing AM toward its true manufacturing potential and providing customers with best-in-class systems, materials, software, application, and services. Learn more: www.farsoon-gl.com.

About TIGITAL® 3D-SET:

TIGITAL® 3D-SET is a leading provider of innovative and sustainable SLS 3D printing thermoset materials that enable our customers to bring their ideas to life with greater speed, precision and cost-effectiveness. Learn more: www.tigital-3dset.com

The project CerAM SLS has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 958174. It is funded by the Austrian Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology, BMK, and is carried out as part of the Production of the Future programme (FFG 892468). It is co-financed with tax funds on the basis of the budget passed by the Saxon State Parliament (SAB 100633121). For more information: Qualification of thermoset-based powders for selective laser sintering of ceramic components — ERA-LEARN