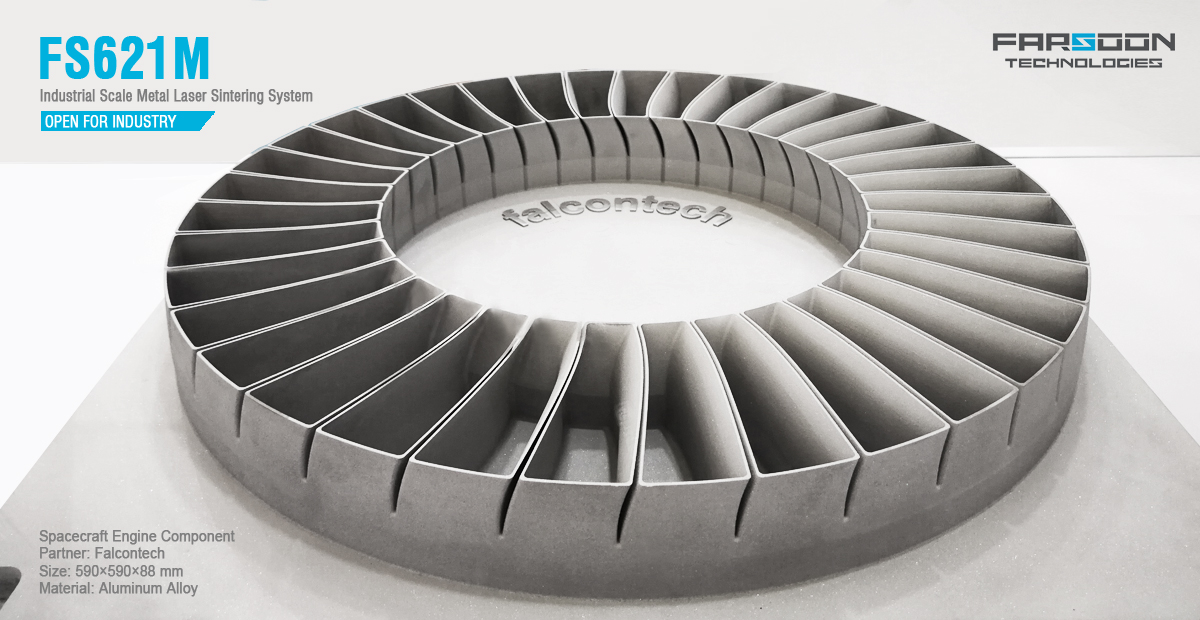

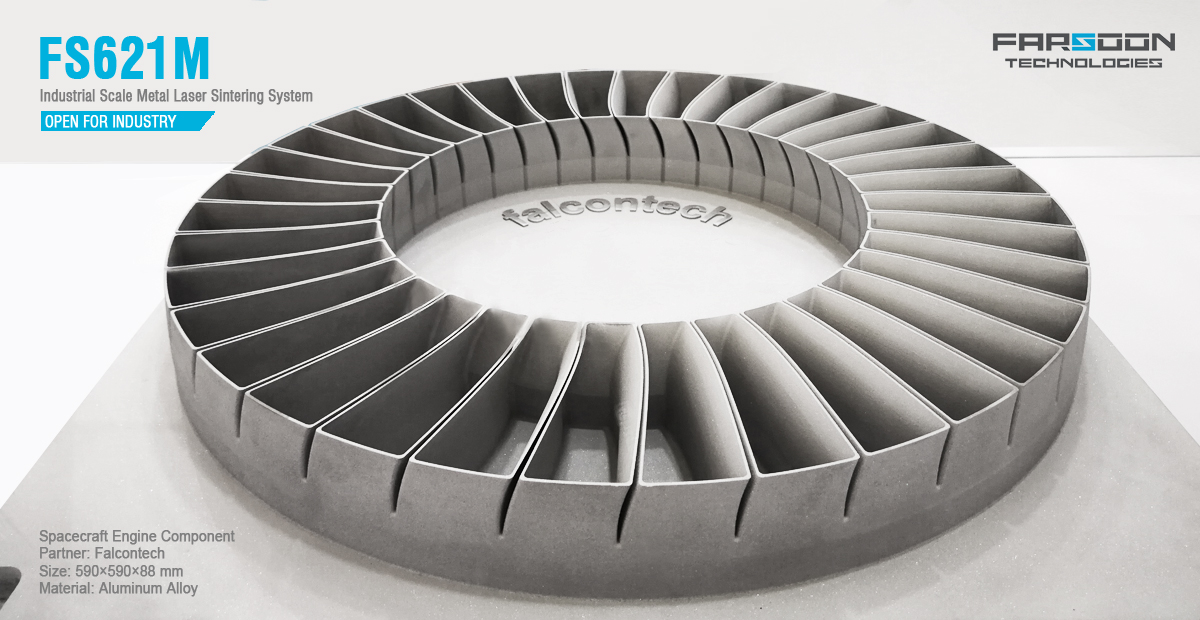

July 9th, 2020 – TCT Asia – Farsoon Technologies is excited to announce the development of the FS621M large-frame metal system. Addressing the metal manufacturing challenges including productivity, size constraints, powder management, process control and factory layout, Farsoon developed the all-new FS621M by co-innovating with key industry partner Falcontech, a leading manufacturing service provider in the aerospace industry, with focuses on extended build cylinder volume and maximum productivity per laser.

Being an important part of Falcontech’s Super AM Factory, Farsoon’s FS621M system gives Falcontech a unparalleled production edge for large aerospace applications. With enhanced additive manufacturing capabilities, Falcontech has succeeded in supporting the development and series production of spacecraft components in a number of aerospace projects. As of today, the installation base of FS621M has reached a total of 7 systems among aerospace and large-scale manufacturing customers who focus on large-volume fabrication, batch production with multi-lasers and processing development of industrial powder materials including titanium alloys, aluminum alloys, nickel-based superalloys and stainless steels.

EXTRA-LARGE BUILD VOLUME WITH 1.1 METER VERTICAL AXIS

Developed with a focus on large build size, Farsoon’s FS621M features one of the largest metal laser sintering build volumes in the additive market, with a build platform size of 620×620mm and vertical axis of 1.1 meter. This expansive build envelope opens new possibilities for large-scale metal production that couldn’t be built before in industries such as aerospace, oil and gas, and many others.

BUILD SPEED + HIGH QUALITY

The FS621M can be equipped with a powerful single 1000W laser or quad 500W lasers allowing for great rates of production. In addition, the FS621M like all Farsoon systems is a truly open platform which offers the user a high degree of control to tailor build parameters for cost-competitive metal additive manufacturing. An advanced dynamic 3-axis scanning system, powerful build process controls & real-time recoating monitoring ensuring the best build quality.

OPTIMIZED FOR OPERATIONAL EASE

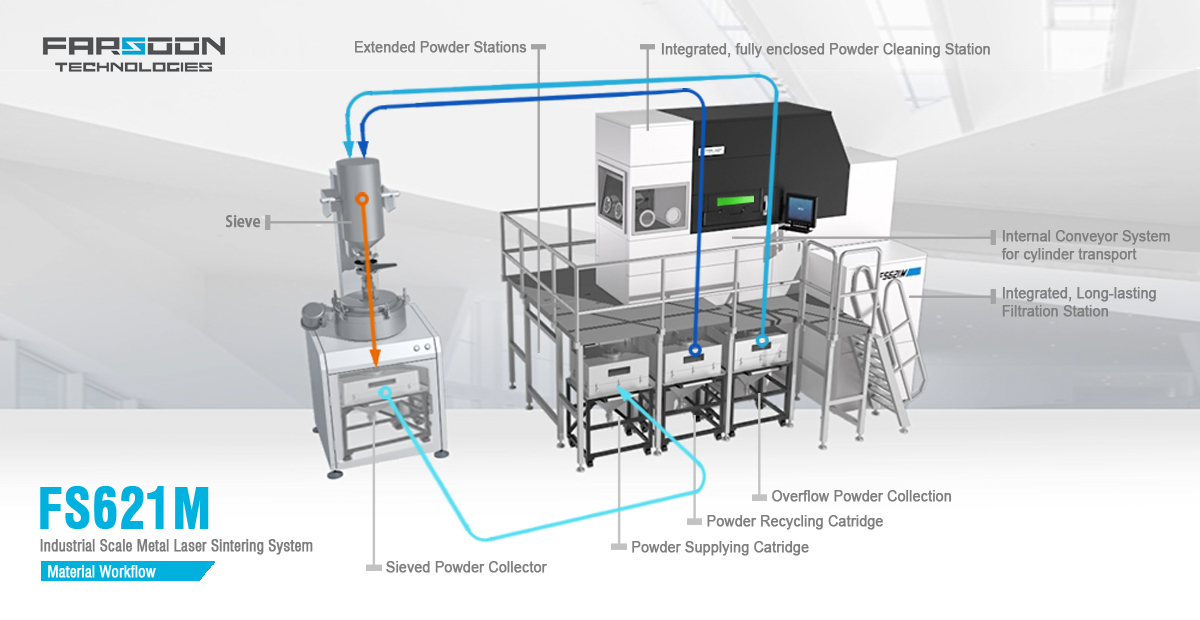

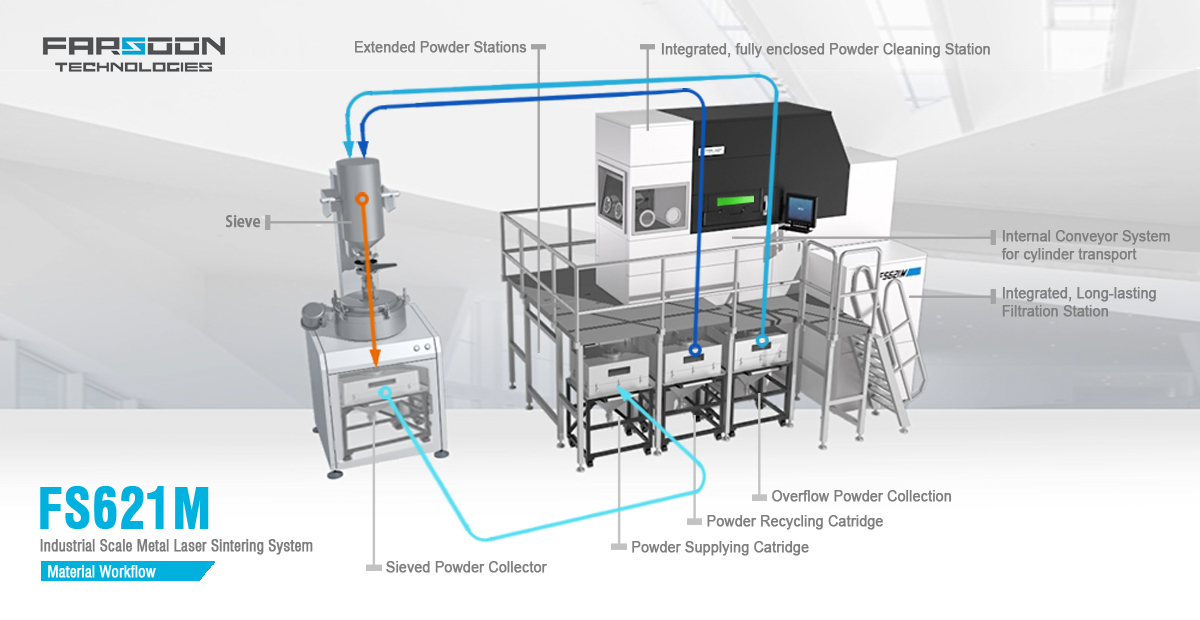

The FS621M’s integrated filter module features secondary circulating system and a dual-station filter design that allows for the exchanging of filters without disturbing the build process. The FS621M powder handling processes share a common powder container design which are used during loading, unloading and sieving procedures. These containers offer fully-sealed power handling, easy transportations between the stations, and safe storage of powder. This partially closed powder system allows for the capability of continuous feeding of powder to the build while retaining the ability to easily exchange and monitor powder quality.

OPEN FOR INDUSTRY

Thanks to Farsoon’s “Open for Industry” philosophy, FS621M users are able to operate with a higher degree of flexibility in parameter setting and material development, which contributes to a variety of processing parameters for specialized applications, including laser settings, scanning path planning, recoating control, size compensation and support design, to help driving innovation and creating added value for industrial customers. This also can help the establishment of processing data base for future development and manufacturing quality control.

Farsoon is eager to work with additional partners in China for the FS621M Beta system. Inquires and customers interested are welcome to contact info@farsoon.com, or visit us at TCT Asia 2020 at booth E5-H07 for more details!

About Farsoon Technologies:

OPEN FOR INDUSTRY – Farsoon is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2017 Farsoon released the first of a new line of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS) Concept, and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe. Farsoon is committed to developing AM towards its true manufacturing potential and providing customers with best-in-class systems, materials, software, applications and services.