Stuttgart, 13.11.2024 – Producing titanium parts using Farsoon’s polymer 3D printers is now a reality, thanks to the innovative ColdMetalFusion technology—a sinter-based additive manufacturing process developed by Headmade Materials. This breakthrough opens new possibilities in high-performance metal AM.

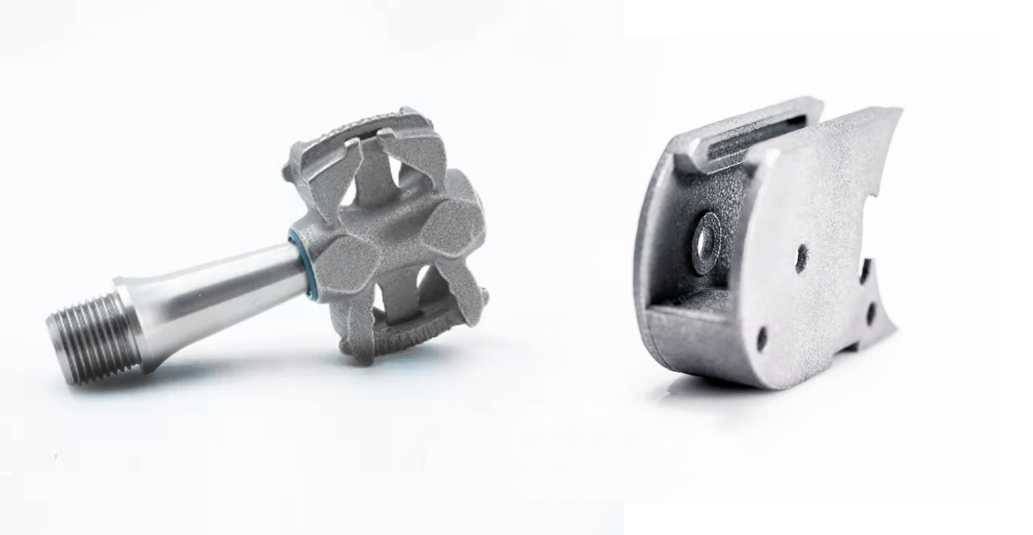

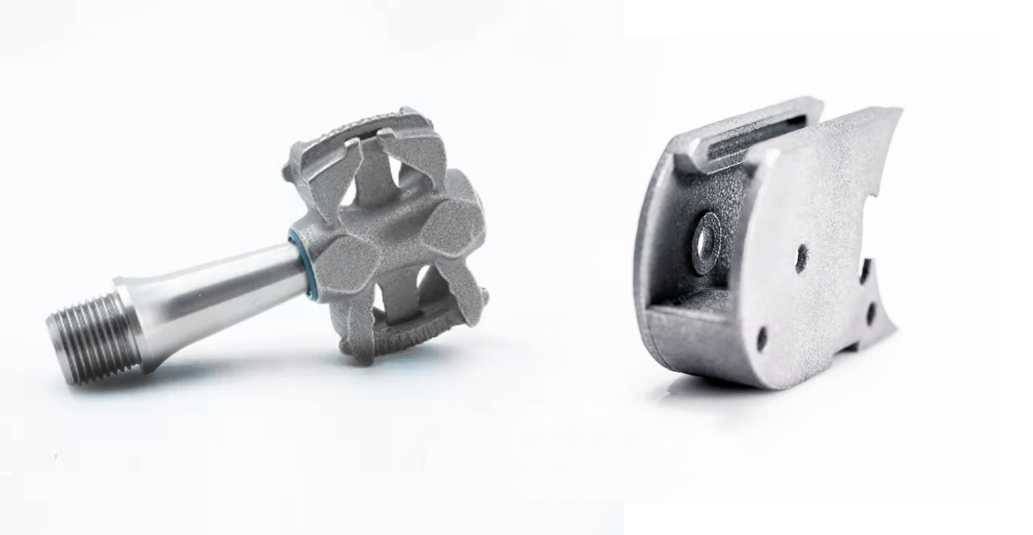

Figure 1: titanium alloy Ti6Al4V parts produced using ColdMetalFusion Technology. Image courtesy: Headmade

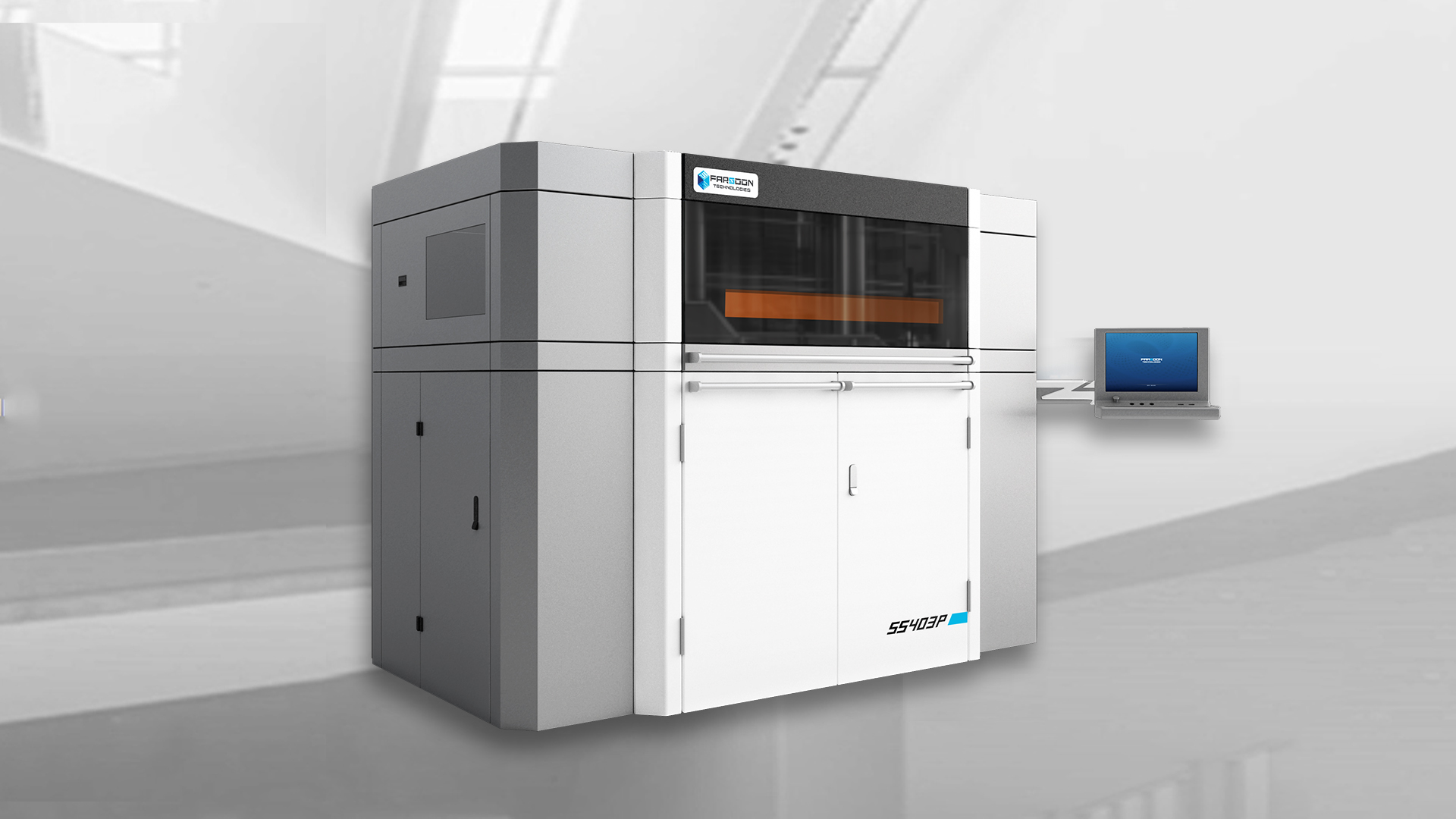

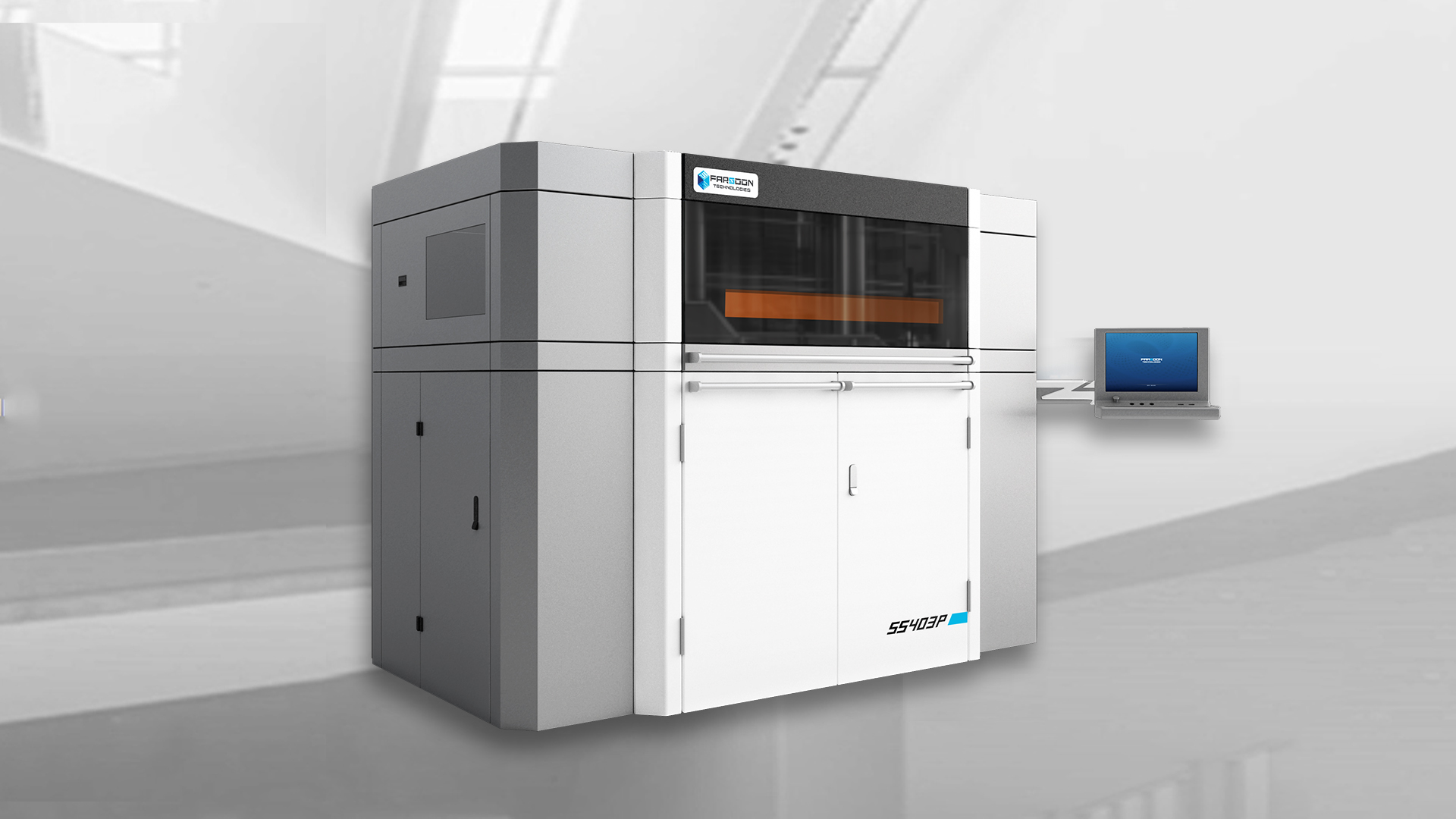

To achieve high-yield, sustainable metal parts production, Headmade Materials has invested in the high-performance Farsoon SS403P Polymer PBF system, now installed at their facility. Leveraging Farsoon’s open parameter strategy, Headmade’s technical team can continuously develop and refine processing parameters across various material families to meet industry-specific applications.

Farsoon’s polymer PBF 3D printer is central to the CMF process, allowing metal parts to be produced without complex support structures. Integrated into the CMF workflow, Headmade Materials has successfully developed CMF-specific Ti64 parameters, exemplified by the production of a large-format impeller for industrial applications. This achievement underscores the scalability and reliability of the CMF process in producing advanced components.

Figure 2: Farsoon Polymer PBF system SS403P. Image courtesy: Farsoon

“By working together with our individual expertise, Farsoon and Headmade Materials are jointly advancing ColdMetalFusion to achieve our common goal of reliable and scalable series metal production. The high productivity of Farsoon’s machines opens up many new opportunities for ColdMetalFusion”, says Christian Fischer, Co-Founder and Managing Director, Headmade Materials GmbH.

This addition marks a significant breakthrough in the cost-effective production of Titanium Grade 5 (Ti64) parts. The collaboration between Headmade and Farsoon is poised to streamline the sourcing of Ti64 components for industries such as aerospace and medical, tackling challenges that have long hindered reliable and affordable production.

Curious About the Future of Ti64 Part Production? Join us at Formnext, Hall 11.0, booth E11, to see the ColdMetalFusion Ti64 impeller part up close and learn more about Farsoon’s groundbreaking technology.

About Farsoon

FARSOON Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Farsoon´s subsidiary FARSOON Europe GmbH (Stuttgart, Germany) provides the whole range of machine portfolio after technical confirmation in China, as well as local service and maintenance activities.

About Headmade Materials

Headmade Materials GmbH develops materials and processes for powder metallurgy. The core technology is the self-developed and in-house manufactured binder systems, which enable customers to produce metal parts cost-effectively and in serial production. Apart of developing standard materials, the company runs bespoke material developments for its customers.

For more information on how Farsoon and Headmade Materials can help you streamline your production process and achieve predictable, high-quality results, contact us at wehelpyou@farsoon-eu.com