Static Firing Skirt on Long March-5 Rocket

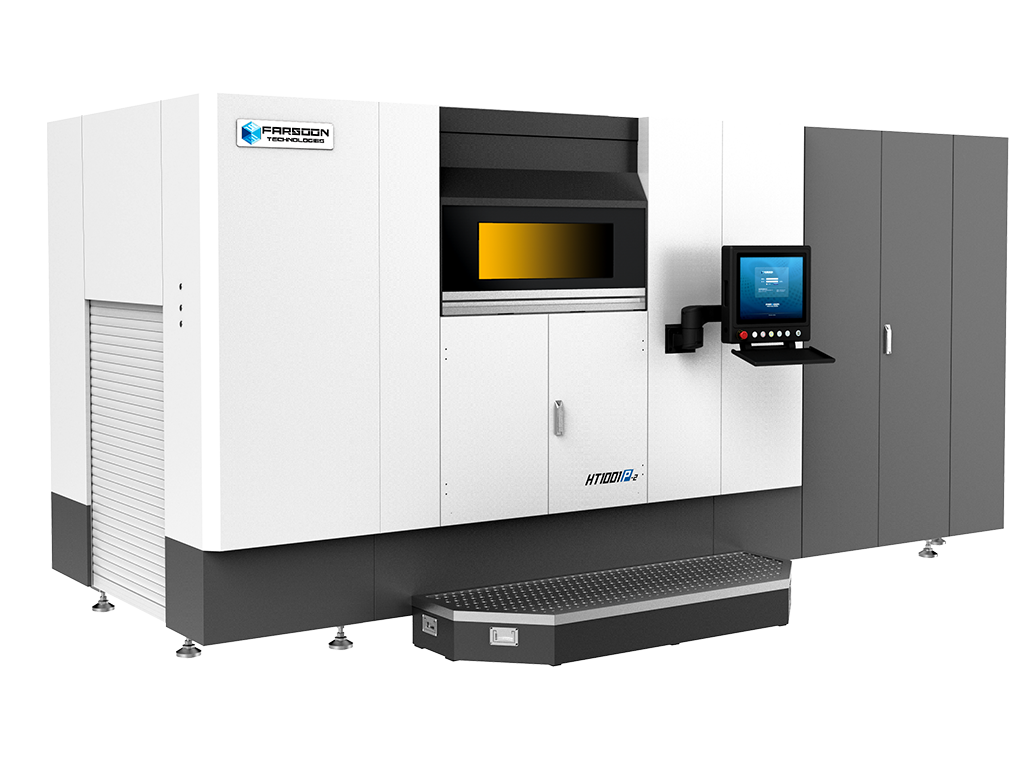

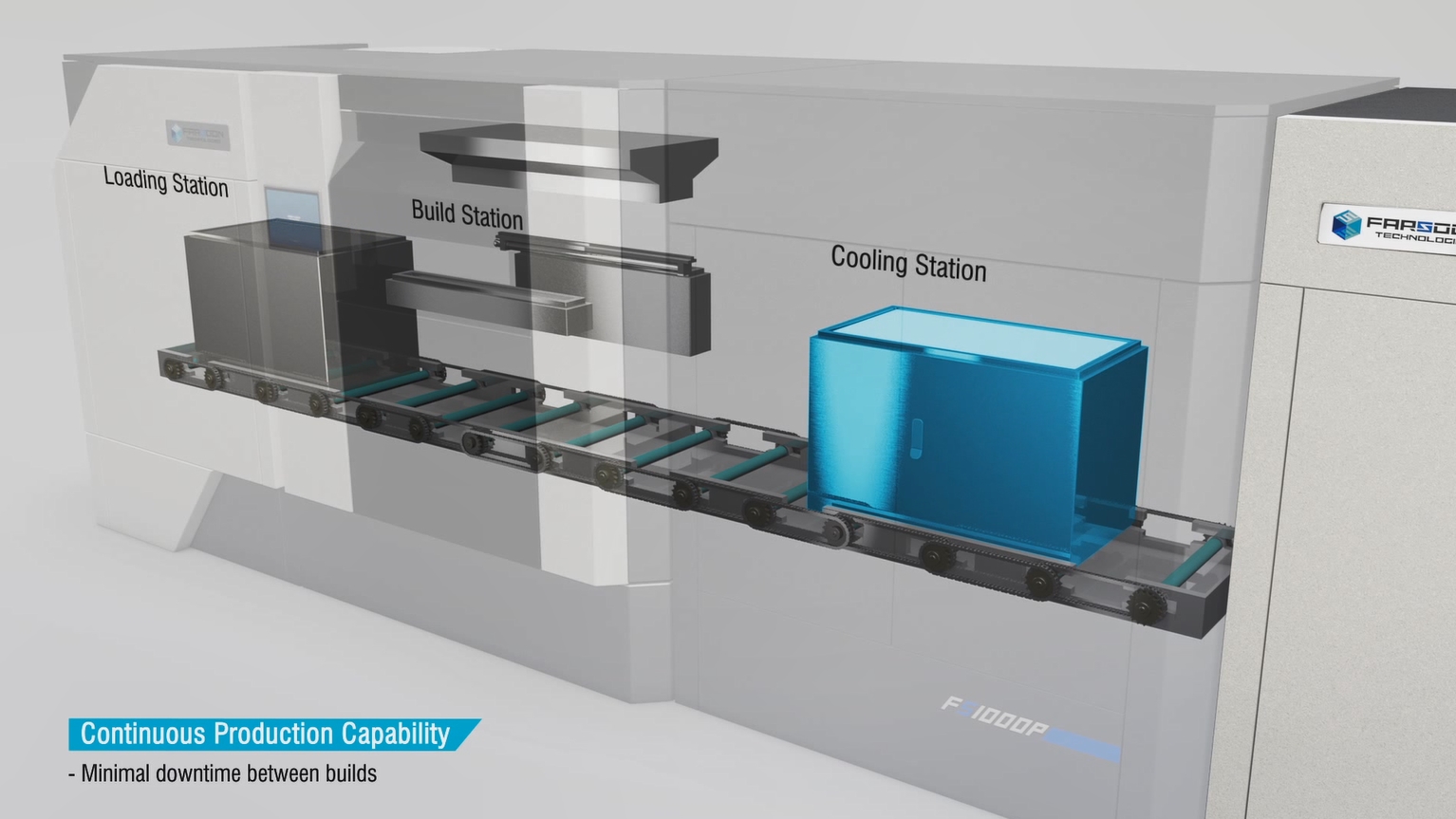

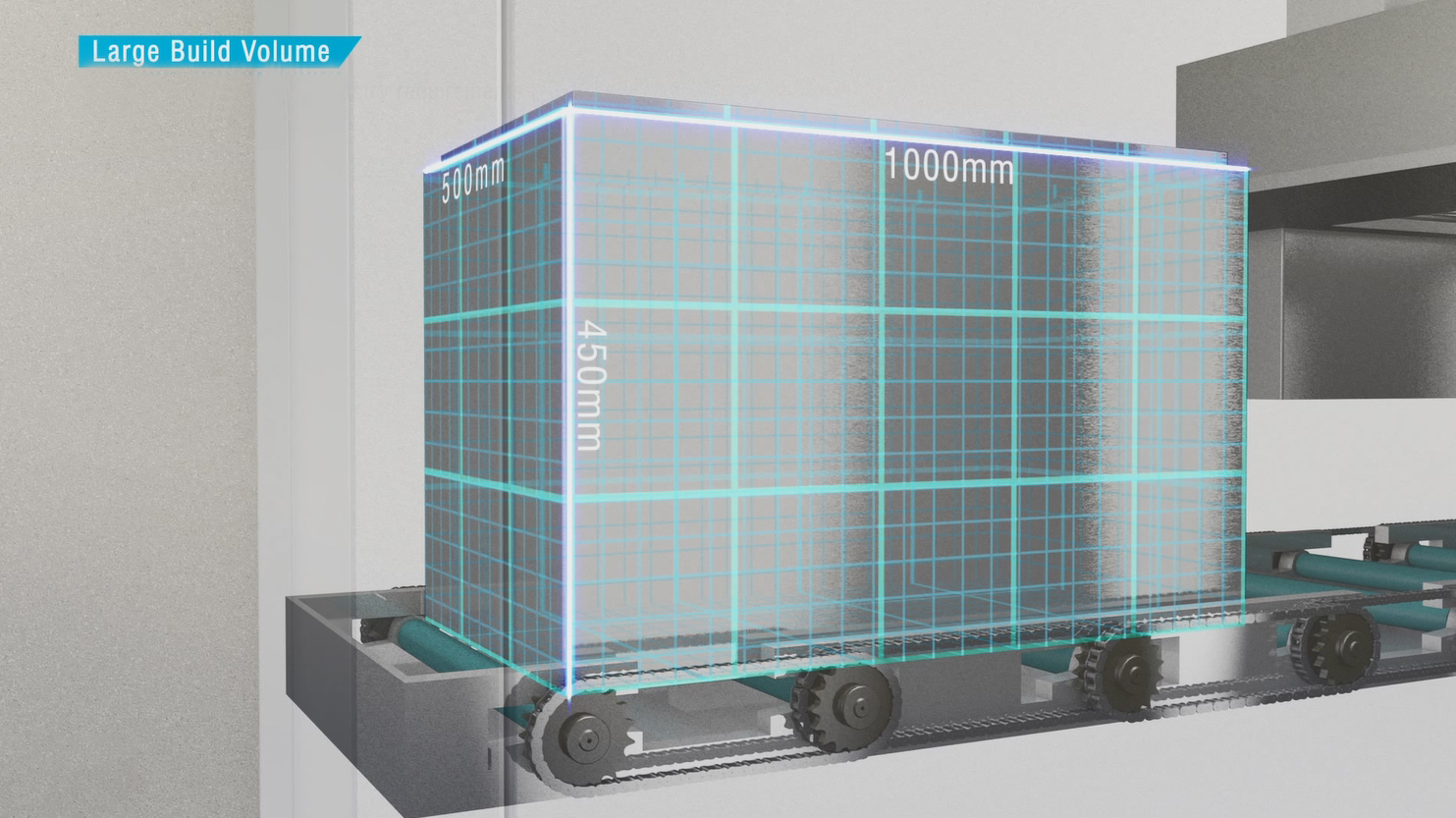

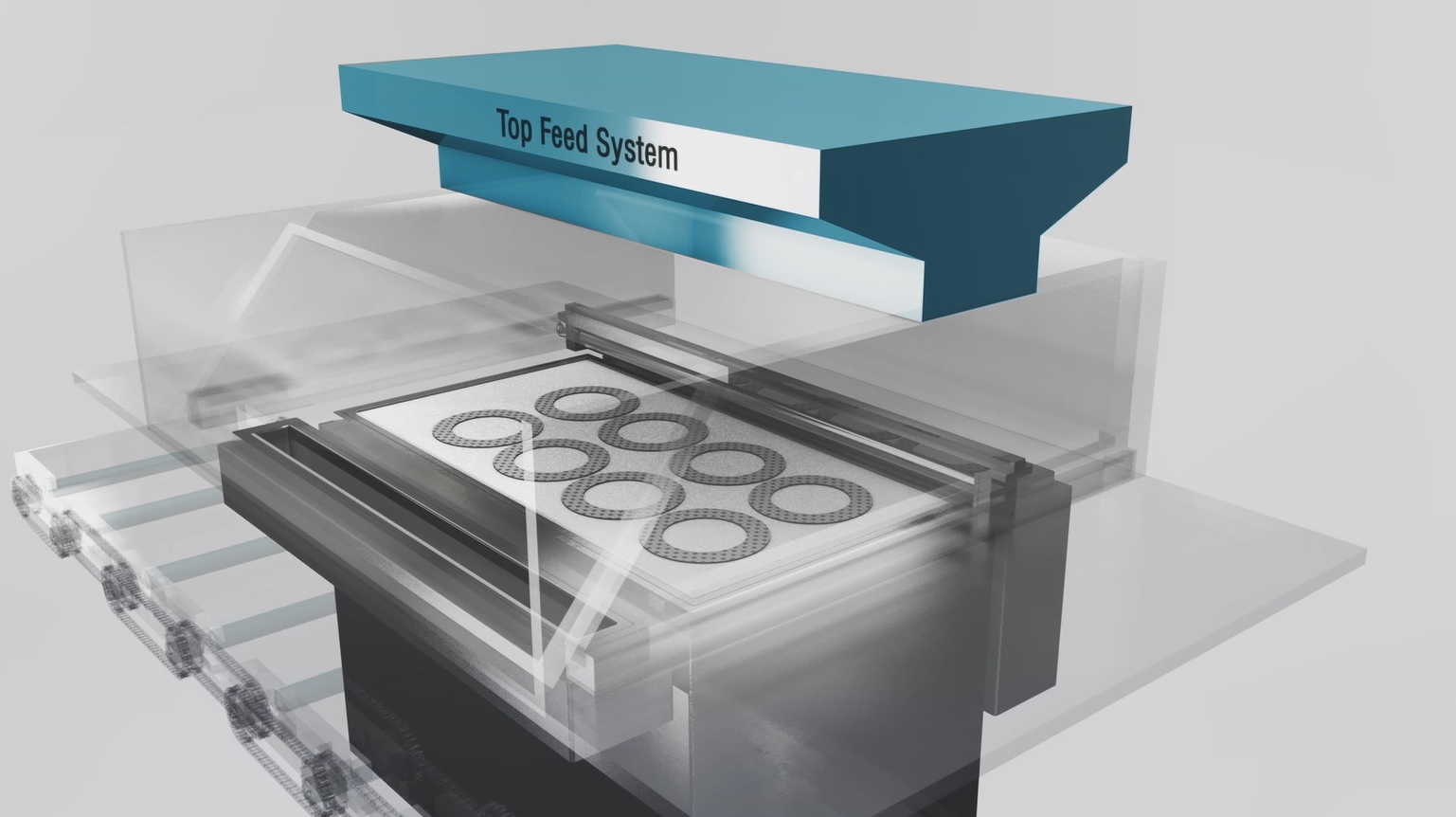

Machine: HT1001P-2

Material: FS3300PA (PA12)

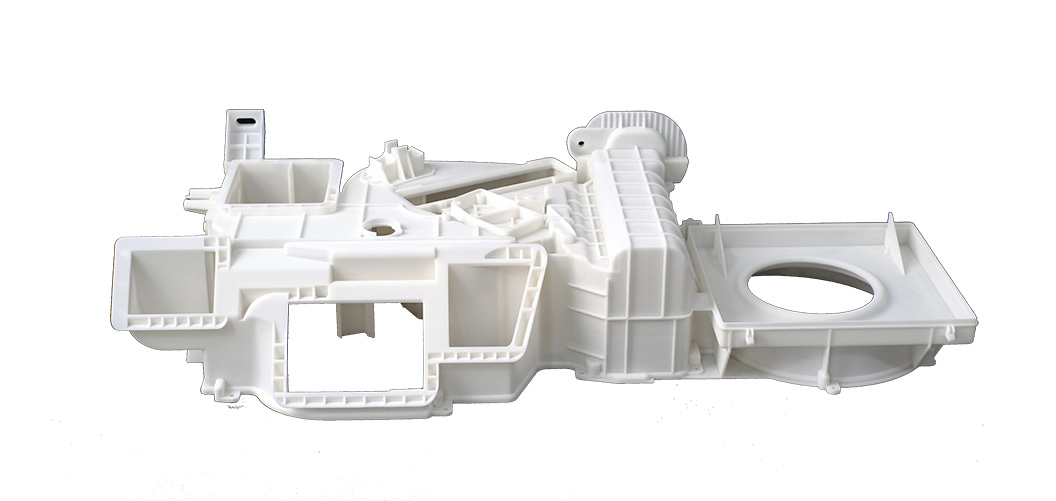

Size: 370 x 100 x 125 mm each

Build Time: 50 pieces produced in 48 hours

Scientists designed the optimized static firing skirt per operating conditions and manufactured the end-use parts using Farsoon HT1001P-2 laser sintering technology and high performance FS3300PA material. Assembled to a 5000mm-diameter cylinder structure, the additively produced static firing skirt features excellent strength and toughness, ease of assembly, good post-processability for water-proofing and salt spray to assess the extreme atmospheric corrosion resistance.

VIEW CASE STUDY